Justin

Well-Known Member

- Joined

- Apr 2, 2009

- Messages

- 570

- Reaction score

- 0

Originally posted by Mister Rogers

Hey Justin,

is the hollow nose opening a desired design element ? If you wanted to you could cut a piece of styrene (plastic) to fit the opening and glue it flush like a plate. It would make sense that it would cut down on drag but since it is at an angle it may try to push the rocket. I don't know how you could sim thatJust a thought....

Sorry I didn't answer this before. Yes, the Vipers on Battlestar Gallactica had hollow noses. You know, you HAVE to have air intakes for your engines while flying in a vacume

I'm not sure how deep the hollow was however. I want to say for the "scale" of mine it should be 1/2" ish deep. I am not going to create the plate though. Just paint the inside flat black to hide the weight.

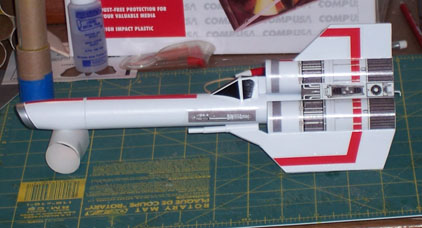

This pic is not related to anything I just said