ECayemberg

Well-Known Member

- Joined

- Jan 21, 2009

- Messages

- 2,876

- Reaction score

- 847

Intro: Ive really enjoyed Mannys Blog-like thread about his trip to the Black Rock Desert, and wanted to document my experience to some degree as well. Now that Manny has returned home from his wayward adventure, its my turn! A little disclaimer here: were about 1.5 months out from the launch and I have a lot to do before then; Ill update the thread as well as Im able, but updates are a lesser priority than being ready on time! The intent of this thread is to loosely cover the activities leading up the event, cover our launches while there, and debrief as appropriate afterward!

The Long and Winding Road:

This journey is a long one; both in time and distance. I discovered high power rocketry with the November/December 1992 issue of High Power Rocketry magazine that featured LDRS XI held at Black Rock. As an 11 year old avid model rocketeer at the time, that issue of HPR sparked the fascination in both higher power rockets and the wonderland outside of Gerlach, Nevada. 20 years later, Im finally going to that place Ive dreamed of for a long time! Though we almost went in 2010, sanity prevailed and we stayed closer to home, attending Airfest 16 in Argonia (another excellent destination as yall know!)

Project Overviews

Im taking two rockets for Balls, two for Hamster Dance, and one for the Bonneville Salt Flats on the way home. Ill try to capture these to some degree in this thread without delving into full blown build threads. In addition to my projects; my travel and flying partners Tom and Marc have requested an additional 8 motors Ill be making for the event.

Balls

20 YEAR ITCH: 20 YEAR ITCHis somewhat of an exotic bird to me; being all aluminum except for the nose. Ive always been enthralled with the Atlantic Research Arcas. Long have I been impressed that such a *small*, common looking rocket could attain altitudes in excess of 150,000. 20 YEAR ITCHis a project that began in the design world as an Arcas and has evolved into what it will be for many reasons (to be discussed later). The rocket is powered by a single stage, mid range O motor.

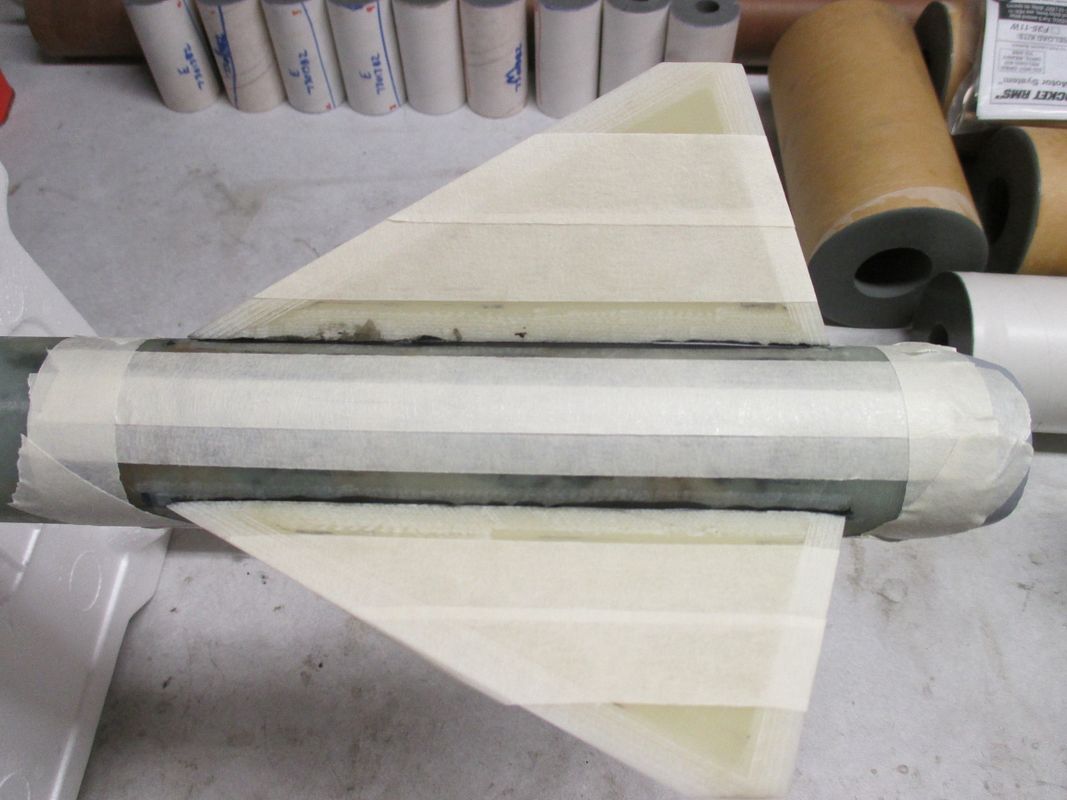

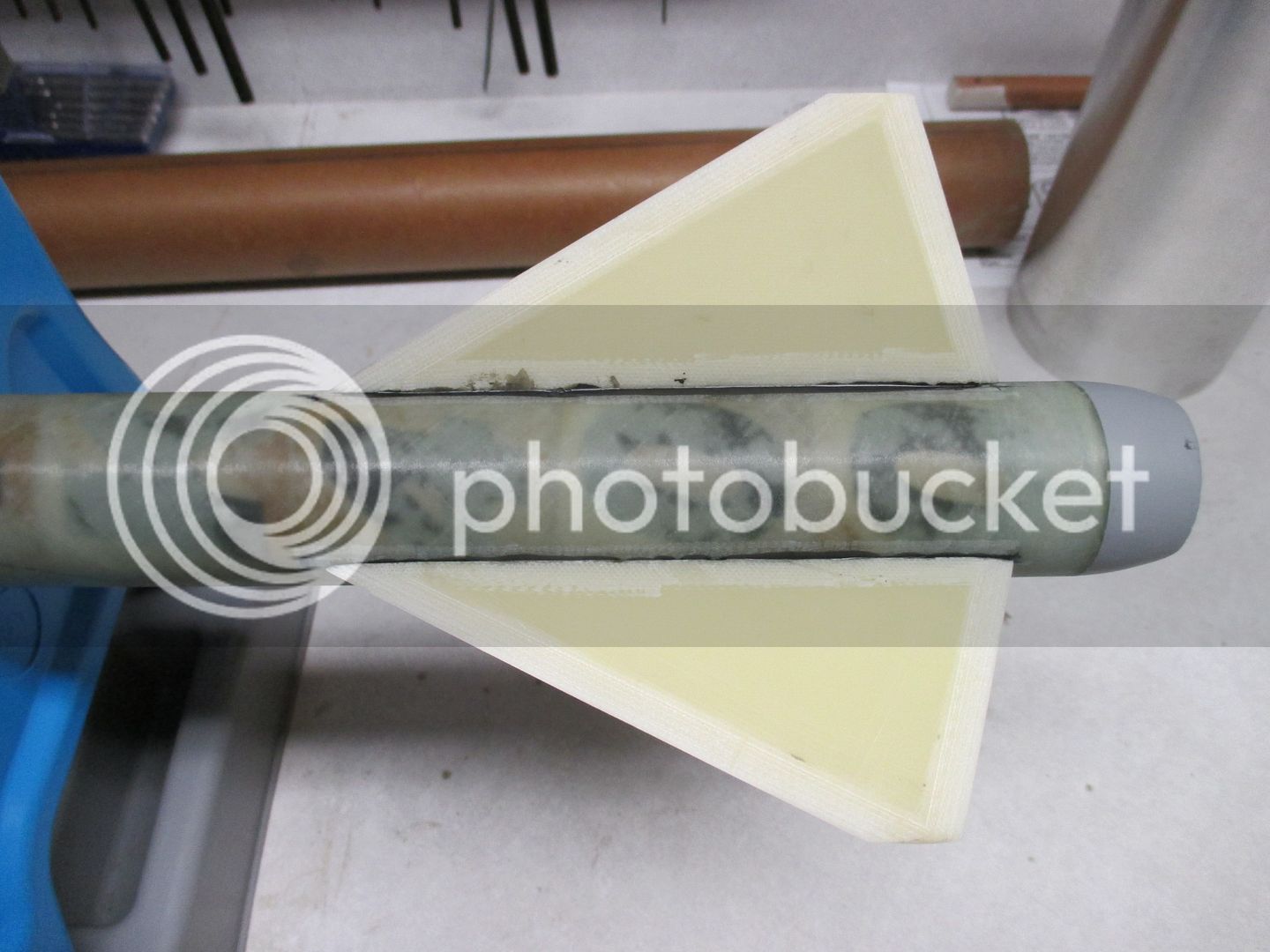

September Fate/Carbon Slipper: a 2 stage 4 to 3 minimum diameter rocket. Carbon Slipper is a 3 min dia all carbon rocket that has flown twice in the single stage configuration; first at LDRS 27 on an M1450W, then again at Thunderstruck 3 on a M3100WT. September Fate is a 4 bare-bones booster for Carbon Slipper; it is a bit unconventional with regard to a standard airframe rocket. Both sections split at the base of their cones for all-out-the-top tethered main recoveries. The pair boosts on a 98-7G N and stages to a moonburner M in AMW 75-7600 hardware.

Hamster Dance

Hamster Dance is a cute little launch held the day before Balls. In short, all motors must be single use, and rockets must be constructed of non-metallic components and have an all up mass of 5 lbs or less.

ISPy: a play on the characteristic specific impulse (ISP); this craft is pronounced I-Spy, which is indicative of a main feature of this motor/airframe. This rocket is a true minimum diameter ship whereas the motor casing is also the airframe. Furthermore, to maximize propellant loading and visual stimulation, the bates grains are linerless; therefore the rocket/motor glows bright red between grains during the second half of the burn (the video of the static motor exemplifies this trait). The motor calculates out to be a 38mm K motor; been done before yet somewhat of a rarity. This rocket has been created to shoot for one of the prized awards.

Alpha Hamster: created with the hope of capturing one of the stated awards and the intent of producing a chuckle or two out of the launch hosts/attendees. This bird is all done, but will be revealed a bit later on.

Salt Flats

Nothing too exciting here: just a simple, durable, and dependable Wildman Jart set to fly on an F or G motor. Marc, Tom, and myself will all be bringing Jarts and keeping them under 3.3 pounds to stay within the Class 1 limitations. Now I just need to decide: red or black?

Pics, additional descriptions, and tall tales of the high seas to follow...for now, a few teaser photos:

-Eric-

The Long and Winding Road:

This journey is a long one; both in time and distance. I discovered high power rocketry with the November/December 1992 issue of High Power Rocketry magazine that featured LDRS XI held at Black Rock. As an 11 year old avid model rocketeer at the time, that issue of HPR sparked the fascination in both higher power rockets and the wonderland outside of Gerlach, Nevada. 20 years later, Im finally going to that place Ive dreamed of for a long time! Though we almost went in 2010, sanity prevailed and we stayed closer to home, attending Airfest 16 in Argonia (another excellent destination as yall know!)

Project Overviews

Im taking two rockets for Balls, two for Hamster Dance, and one for the Bonneville Salt Flats on the way home. Ill try to capture these to some degree in this thread without delving into full blown build threads. In addition to my projects; my travel and flying partners Tom and Marc have requested an additional 8 motors Ill be making for the event.

Balls

20 YEAR ITCH: 20 YEAR ITCHis somewhat of an exotic bird to me; being all aluminum except for the nose. Ive always been enthralled with the Atlantic Research Arcas. Long have I been impressed that such a *small*, common looking rocket could attain altitudes in excess of 150,000. 20 YEAR ITCHis a project that began in the design world as an Arcas and has evolved into what it will be for many reasons (to be discussed later). The rocket is powered by a single stage, mid range O motor.

September Fate/Carbon Slipper: a 2 stage 4 to 3 minimum diameter rocket. Carbon Slipper is a 3 min dia all carbon rocket that has flown twice in the single stage configuration; first at LDRS 27 on an M1450W, then again at Thunderstruck 3 on a M3100WT. September Fate is a 4 bare-bones booster for Carbon Slipper; it is a bit unconventional with regard to a standard airframe rocket. Both sections split at the base of their cones for all-out-the-top tethered main recoveries. The pair boosts on a 98-7G N and stages to a moonburner M in AMW 75-7600 hardware.

Hamster Dance

Hamster Dance is a cute little launch held the day before Balls. In short, all motors must be single use, and rockets must be constructed of non-metallic components and have an all up mass of 5 lbs or less.

ISPy: a play on the characteristic specific impulse (ISP); this craft is pronounced I-Spy, which is indicative of a main feature of this motor/airframe. This rocket is a true minimum diameter ship whereas the motor casing is also the airframe. Furthermore, to maximize propellant loading and visual stimulation, the bates grains are linerless; therefore the rocket/motor glows bright red between grains during the second half of the burn (the video of the static motor exemplifies this trait). The motor calculates out to be a 38mm K motor; been done before yet somewhat of a rarity. This rocket has been created to shoot for one of the prized awards.

Alpha Hamster: created with the hope of capturing one of the stated awards and the intent of producing a chuckle or two out of the launch hosts/attendees. This bird is all done, but will be revealed a bit later on.

Salt Flats

Nothing too exciting here: just a simple, durable, and dependable Wildman Jart set to fly on an F or G motor. Marc, Tom, and myself will all be bringing Jarts and keeping them under 3.3 pounds to stay within the Class 1 limitations. Now I just need to decide: red or black?

Pics, additional descriptions, and tall tales of the high seas to follow...for now, a few teaser photos:

-Eric-

Last edited:

.

.