g_boxwood

Well-Known Member

- Joined

- Jan 20, 2009

- Messages

- 564

- Reaction score

- 0

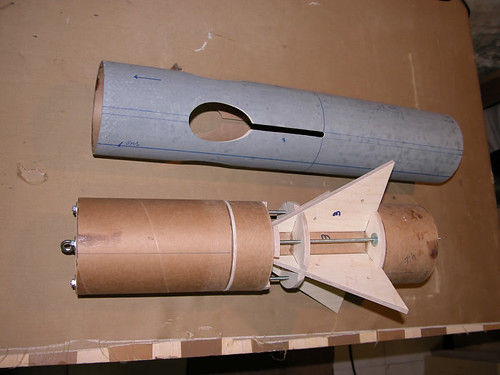

Here we go again... I didn't get what happened to TRF but since this project isn't finished yet I must resume it somehow.

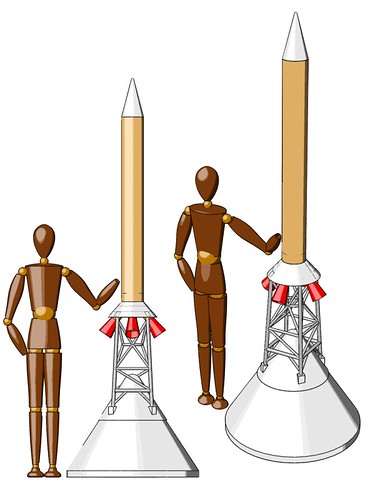

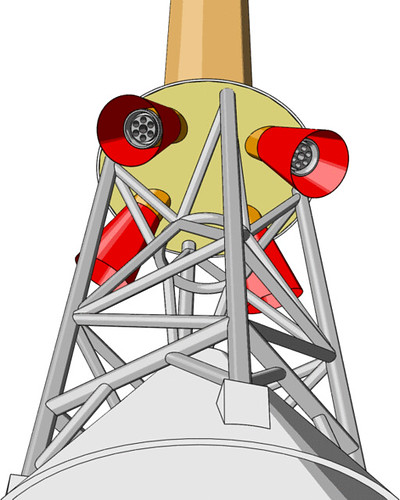

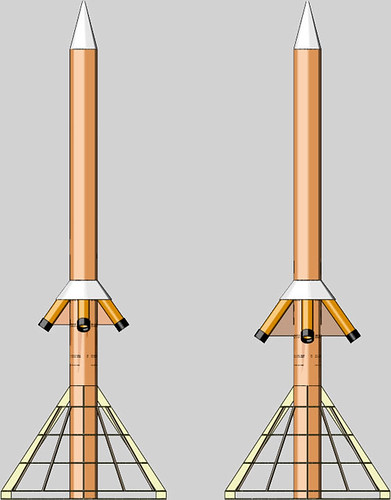

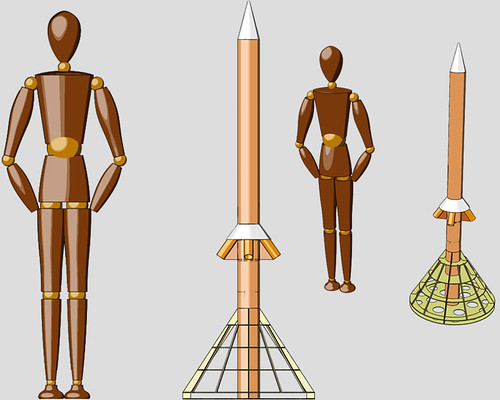

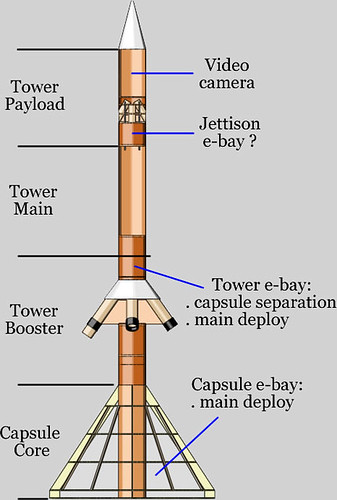

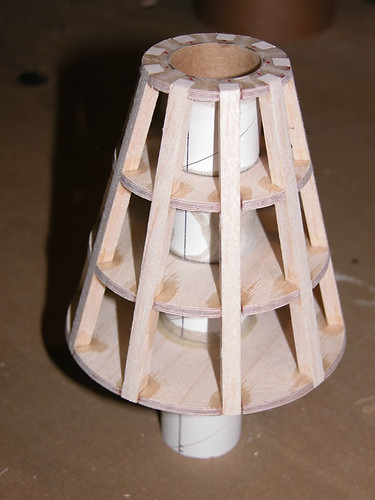

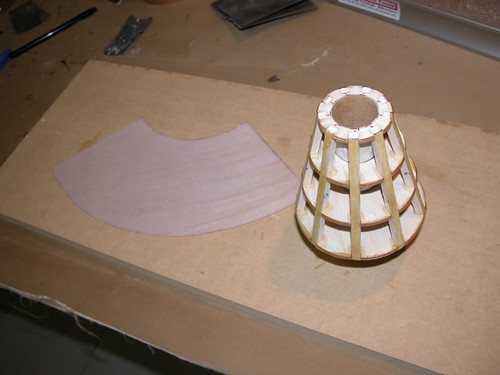

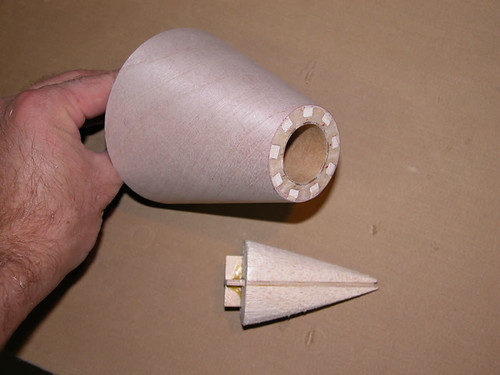

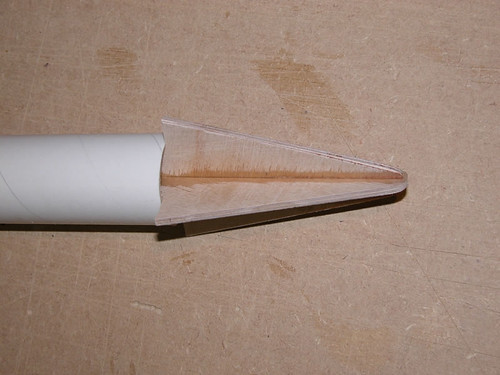

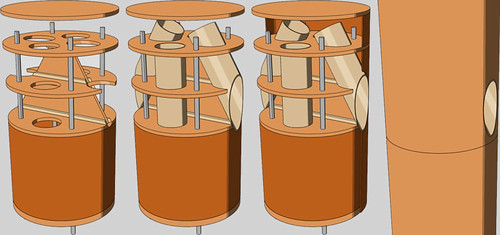

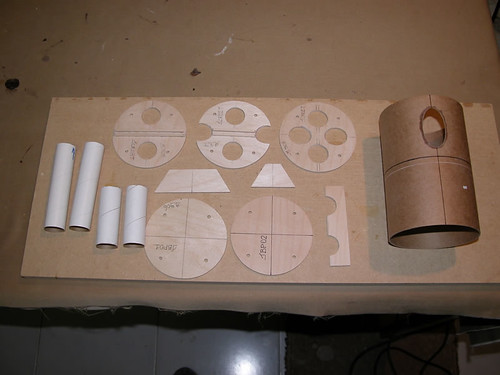

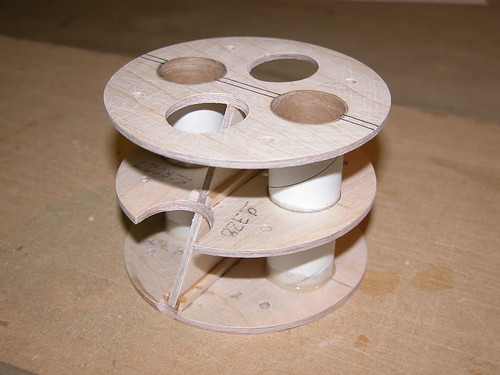

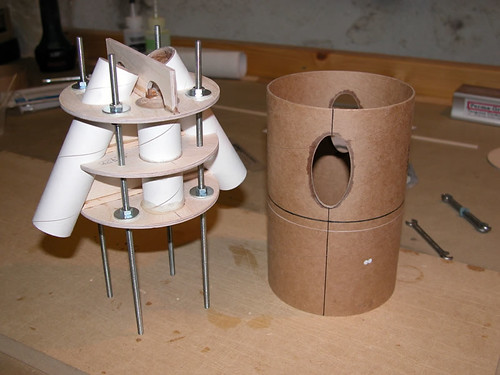

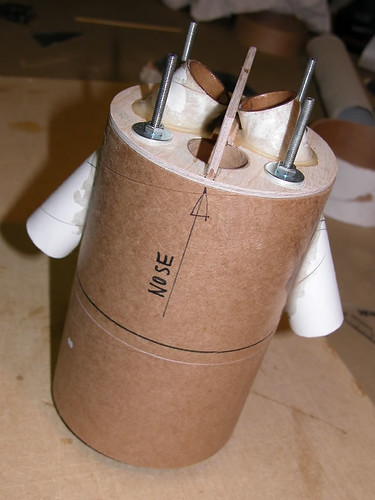

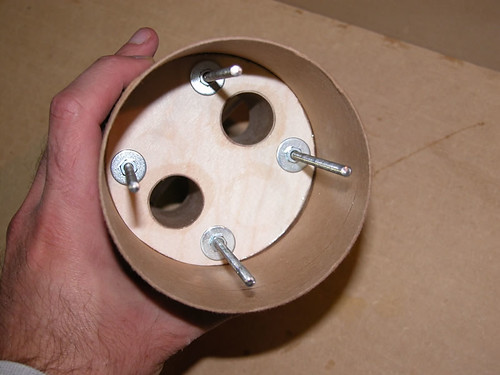

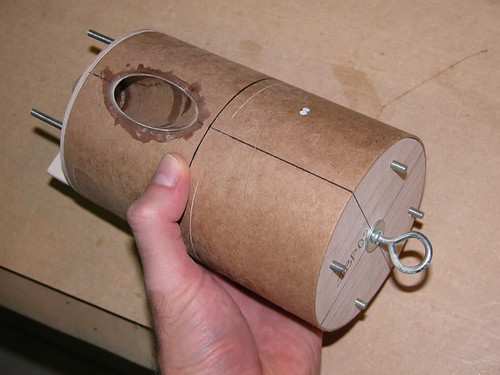

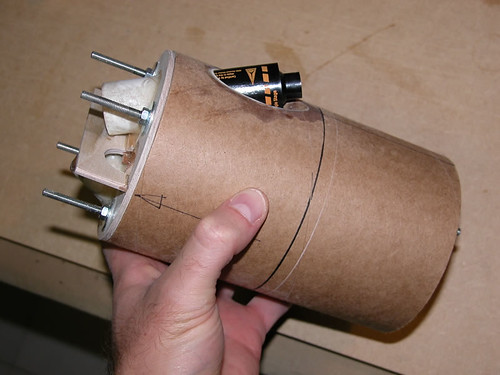

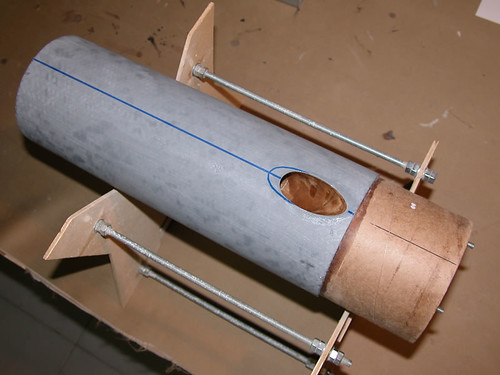

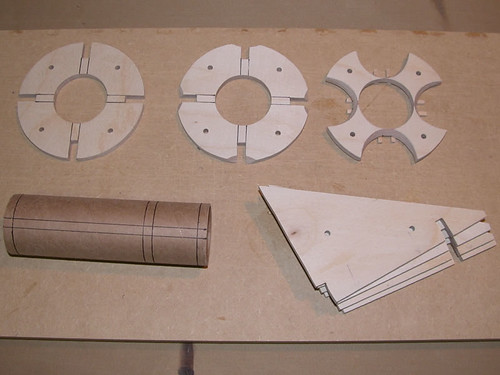

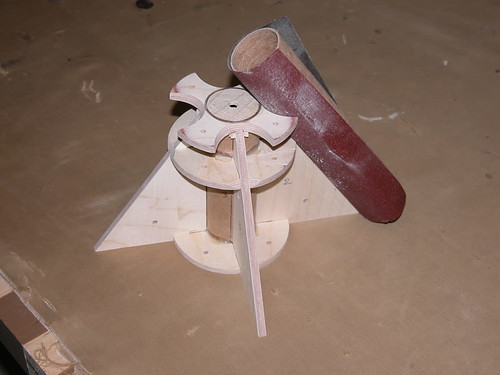

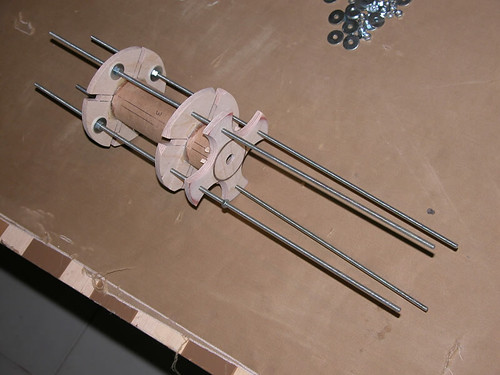

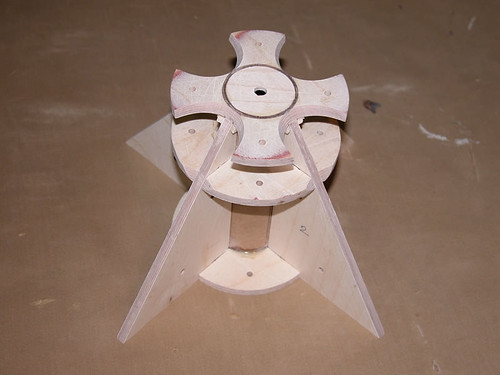

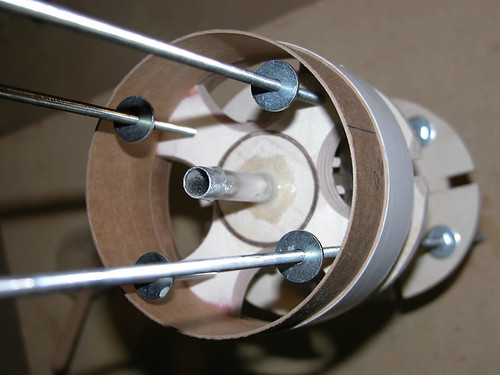

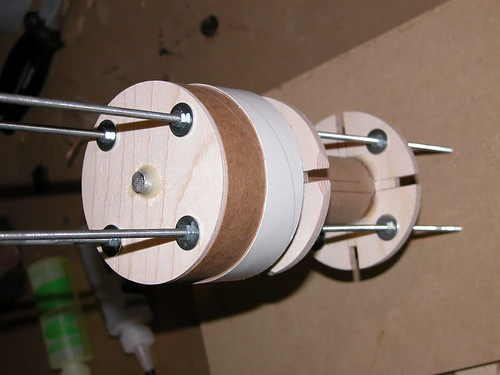

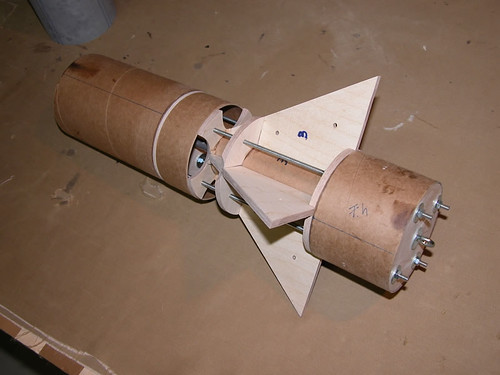

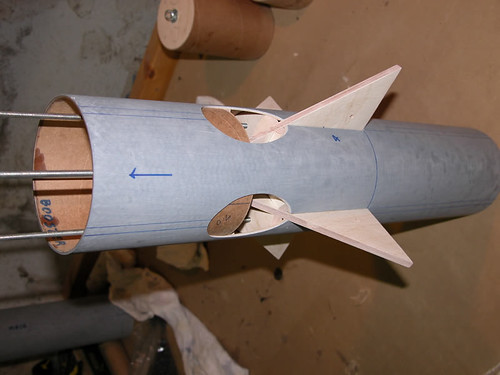

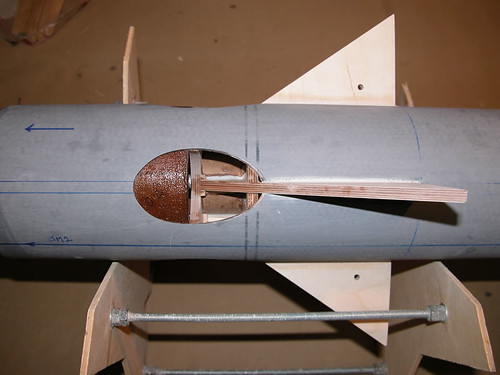

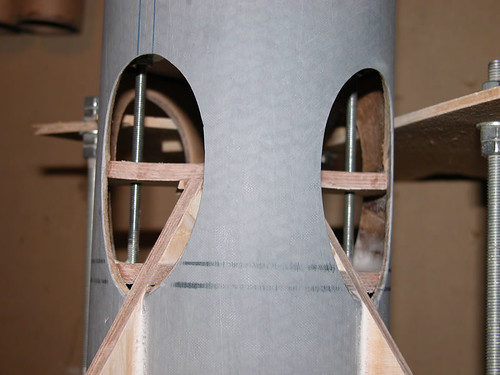

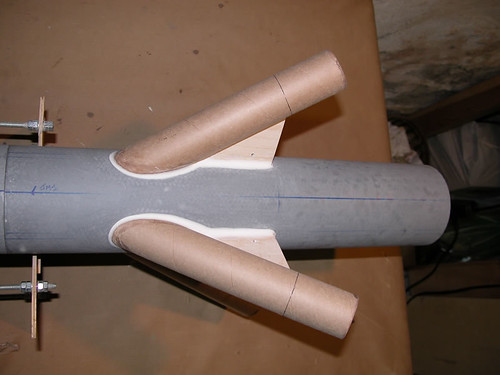

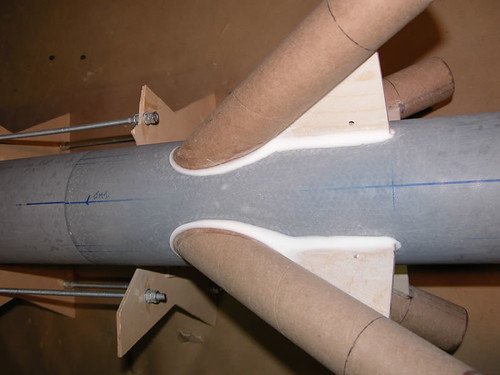

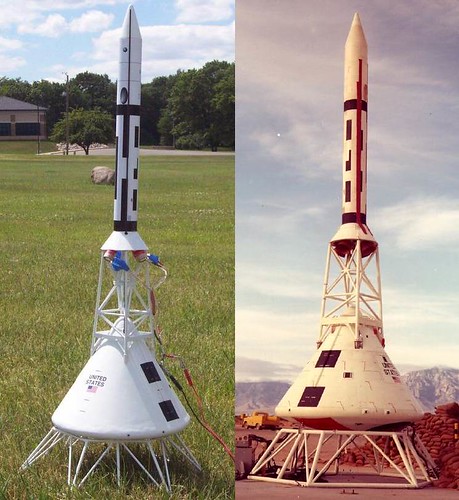

We're talking about the Apollo Launch Escape System...

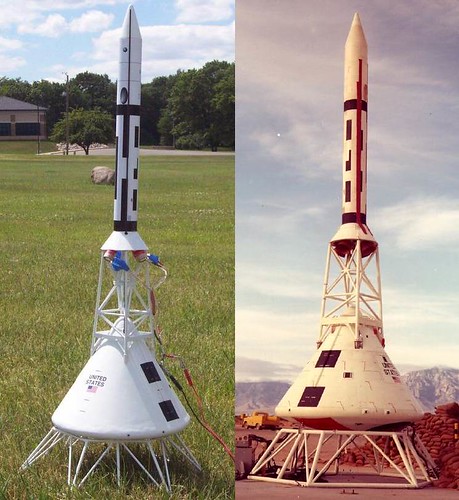

... that Gordon and Gus already modeled around BT-70 tubing: as you see the results speak for themselves, both from the craftmanship and the flight perfomance point of view:

We're talking about the Apollo Launch Escape System...

... that Gordon and Gus already modeled around BT-70 tubing: as you see the results speak for themselves, both from the craftmanship and the flight perfomance point of view: