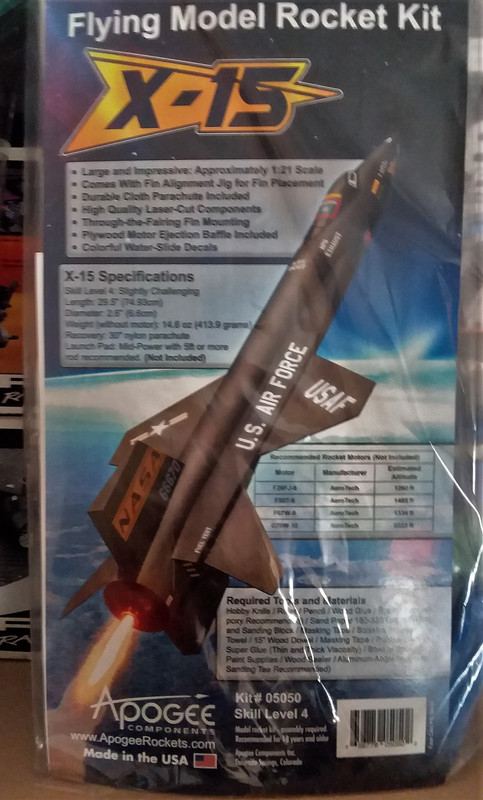

Hey everyone. Got my Apogee X-15 kit. I'm really excited about this kit and the rocket plane it's based on. I thought I'd start this thread so that people could post some tips. This is not a full on build thread. I'm sure some people will do that sometime soon, but I don't have the patience to remember to take all the pics and to post them. But, I do have the wherewithal to post some individual tips to maybe help others. Please feel free to post your tips here. Also, feel free to link to your build thread too.

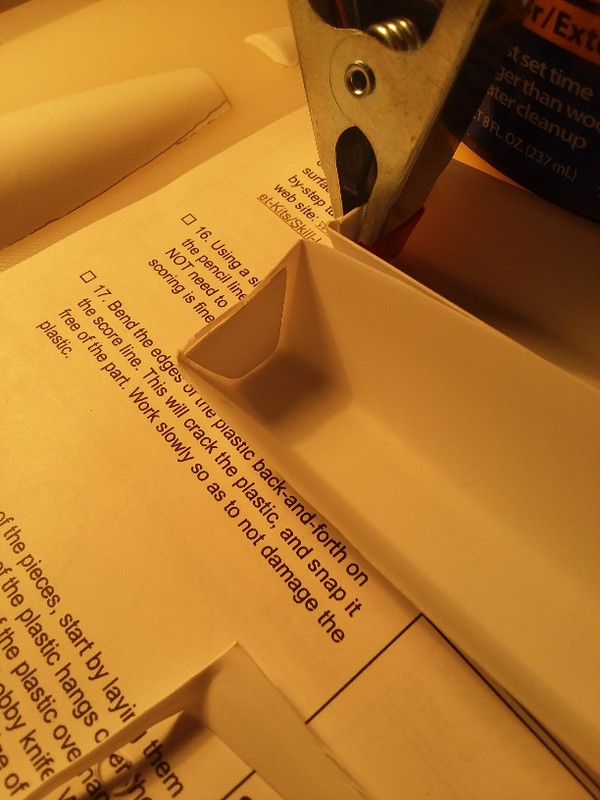

Here's my first tip: Watch the video on Apogee's site for cutting out the vacuum formed sheet!! I was kind of freaked out when I first opened the kit and saw the lack of definition on some of the edges. Tim Van Milligan shows you on the video exactly how to mark the lines and cut it out. I haven't cut it yet but it completely made sense after I watched the video and I have marked up very clean cut lines thus far. I'll take my time and get it right.

Here's my first tip: Watch the video on Apogee's site for cutting out the vacuum formed sheet!! I was kind of freaked out when I first opened the kit and saw the lack of definition on some of the edges. Tim Van Milligan shows you on the video exactly how to mark the lines and cut it out. I haven't cut it yet but it completely made sense after I watched the video and I have marked up very clean cut lines thus far. I'll take my time and get it right.