Rail Dawg

Always learning!!!

The guys on here have been instrumental on getting me to think more than one way about an issue.

And I’ll lay odds that those that have read this thread have picked up a lot of great techniques themselves.

In the peanut gallery there is a gent who even goes so far as to say I’m a danger to the hobby. Of course he stays out of the arena and lobs the rocks in. Don’t know about all y’all but I have seen some carnage and some beautiful flights out there on the playa. Black Rock is where we go to test our rockets and to push the boundaries of amateur rocketry.

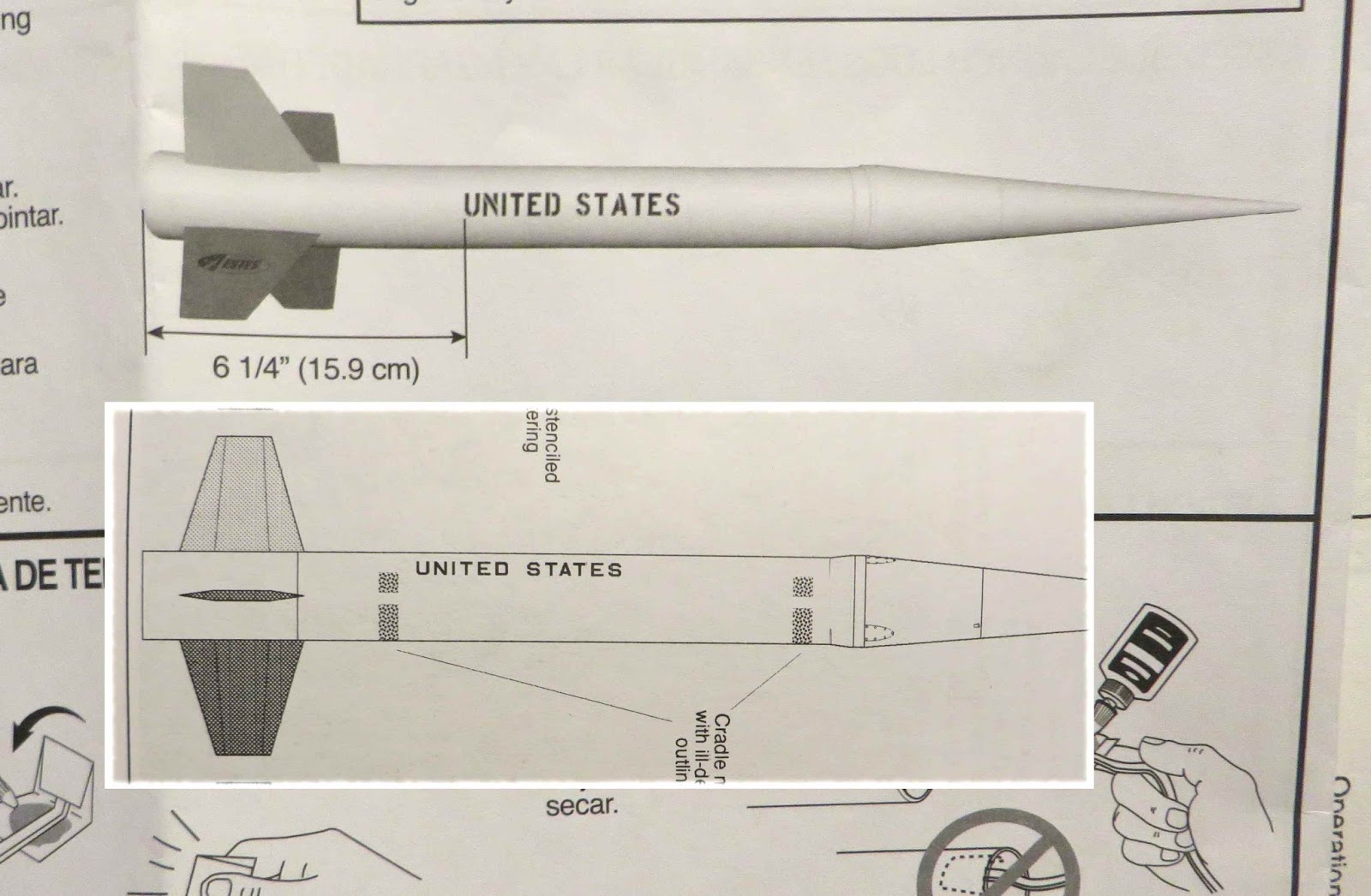

This rocket was built with some outstanding input from the forum. Did I use every idea given? Of course not. But every post from each of you was read and evaluated. And the build on this rocket reflects what I think are the best practices for safety.

This rocket will be approved to fly at a TRA-sponsored event. There are several important gates to pass for approval and those gates will be satisfied.

Never let the naysayers try to bring you down. If I listened to those in the cheap seats hurling insults I’d never have had this outstanding experience. Thanks to all of you for participating in this thread.

And yes Pat G is right but yes there will be a larger rocket built lol.

This R rocket is a great stepping stone. Am having a blast.

Chuck C.

And I’ll lay odds that those that have read this thread have picked up a lot of great techniques themselves.

In the peanut gallery there is a gent who even goes so far as to say I’m a danger to the hobby. Of course he stays out of the arena and lobs the rocks in. Don’t know about all y’all but I have seen some carnage and some beautiful flights out there on the playa. Black Rock is where we go to test our rockets and to push the boundaries of amateur rocketry.

This rocket was built with some outstanding input from the forum. Did I use every idea given? Of course not. But every post from each of you was read and evaluated. And the build on this rocket reflects what I think are the best practices for safety.

This rocket will be approved to fly at a TRA-sponsored event. There are several important gates to pass for approval and those gates will be satisfied.

Never let the naysayers try to bring you down. If I listened to those in the cheap seats hurling insults I’d never have had this outstanding experience. Thanks to all of you for participating in this thread.

And yes Pat G is right but yes there will be a larger rocket built lol.

This R rocket is a great stepping stone. Am having a blast.

Chuck C.