BlazingAngel665

Propulsion Lead, Agile Space Industries

- Joined

- Nov 17, 2015

- Messages

- 87

- Reaction score

- 3

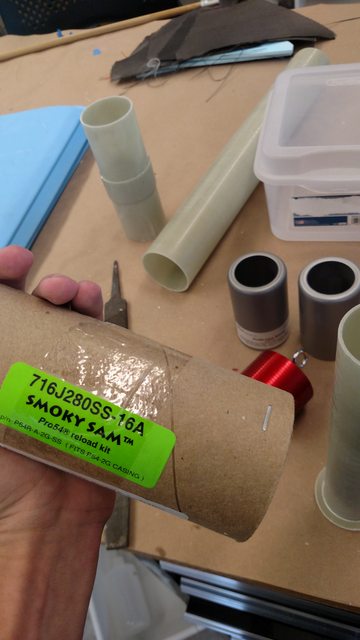

I'm starting a new project, mostly because I picked up a Little Dog in the Yard Sale. My university's shipping department lost it for a little bit because of a mix up, but they recently found it. BUILD TIME!

Motor Mount?

Nah! It's minimum diameter time! This is my first minimum diameter, so if I do a stupid, please say something.

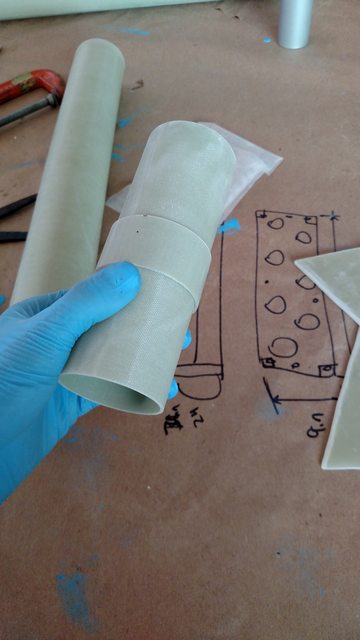

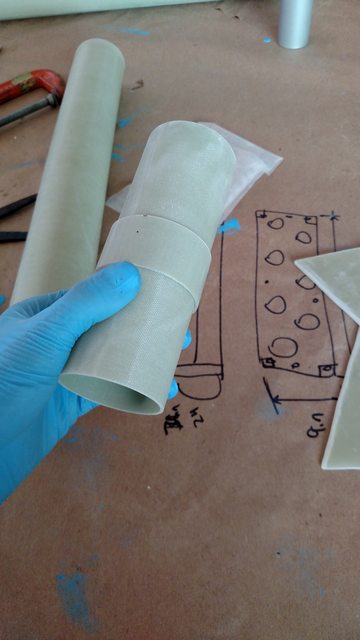

Fiberglass PPE keeps the splinters out of me.

Cutting switchband piece from forward fuselage.

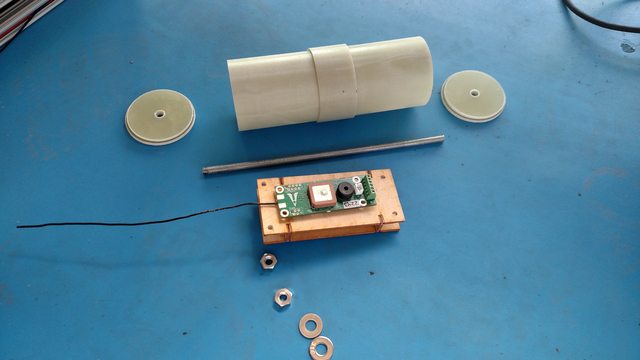

Stepped bulkheads, these make my day when they fit perfectly.

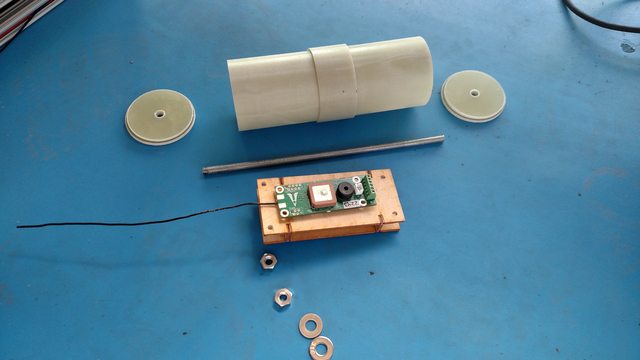

Avionics hardware. I'm using a TeleMetrum 2.0 for recovery and telemetry. I'm looking for over 24,000 ft on this bird so the GPS is essential for recovery. I have a seven element yagi for the ground station. All aluminium hardware to maximize the altitude per motor.

Nose cone is polished up.

All the bits are layed out. The next project is the fin attachment and tip to tip layup. I'm hoping for my first flight to be on Saturday the 30th. I have a J280 which should send this 6,600ft above Berwick, ME. This vehicle's name is "Laika" which is the name of the first living creature to orbit the Earth. I'm thinking a Soviet Army Green with a red and yellow star to show good comradeship. [EDIT: pretend I spelled that right]

Motor Mount?

Nah! It's minimum diameter time! This is my first minimum diameter, so if I do a stupid, please say something.

Fiberglass PPE keeps the splinters out of me.

Cutting switchband piece from forward fuselage.

Stepped bulkheads, these make my day when they fit perfectly.

Avionics hardware. I'm using a TeleMetrum 2.0 for recovery and telemetry. I'm looking for over 24,000 ft on this bird so the GPS is essential for recovery. I have a seven element yagi for the ground station. All aluminium hardware to maximize the altitude per motor.

Nose cone is polished up.

All the bits are layed out. The next project is the fin attachment and tip to tip layup. I'm hoping for my first flight to be on Saturday the 30th. I have a J280 which should send this 6,600ft above Berwick, ME. This vehicle's name is "Laika" which is the name of the first living creature to orbit the Earth. I'm thinking a Soviet Army Green with a red and yellow star to show good comradeship. [EDIT: pretend I spelled that right]

Last edited: