I have had a long term fascination with tube fin rockets. There is just something about the way the fly.

So I decided to build a mid power tube fin rocket designed for anything from an F composite up to a long burn H.

The body tube and fins would be made from cheap postal tubes with a long LOC 29mm motor mount tube. Aero Pack motor retainer and everything else 3d printed.

Nose cone ready for sanding after a long print.

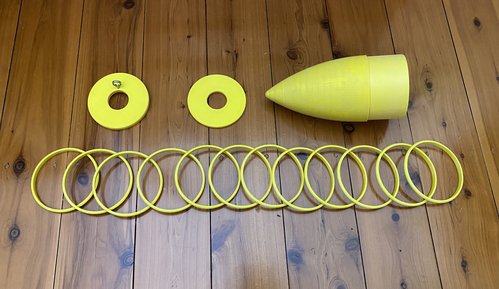

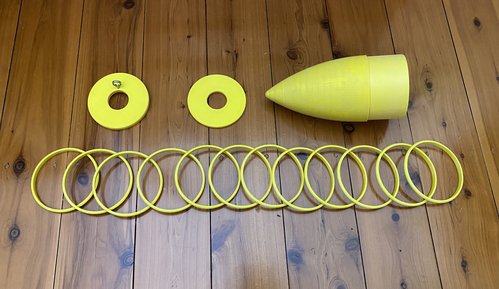

Nose cone, centering rings and fin reinforcement rings.

Fin rings installed. Designed to protect the tube fins on landing.

Extra long motor mount tube. Helps with deployment and holds the chute up in the nose cone.

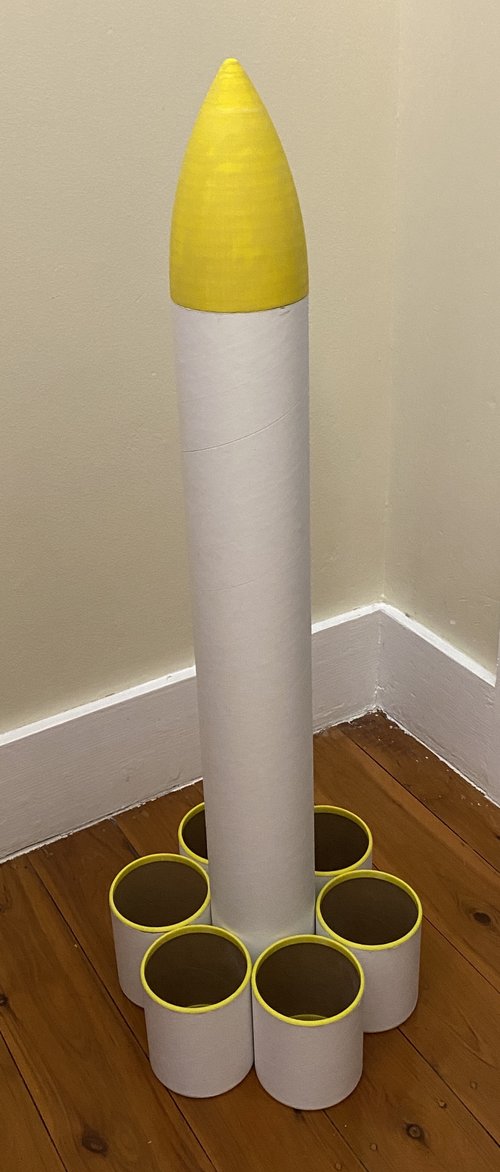

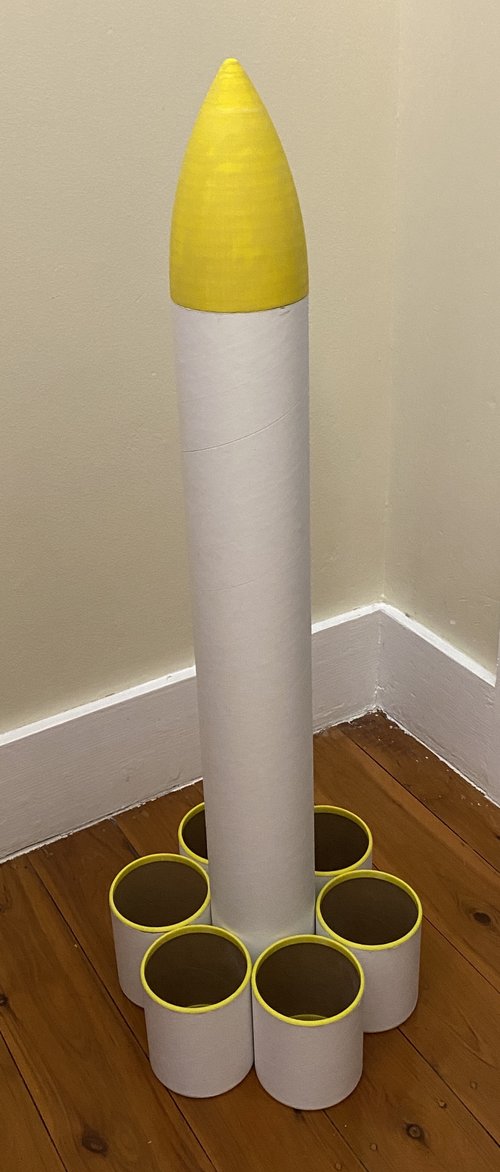

First dry fit.

Dry fit with nylon bolts to help align the tube fins. Rail button at the top of the photo. Needed a stand-off to clear the inside of the tube fin.

Paint scheme based on colours found in the shed.

Some stripes and a vinyl decal finish the job.

Plenty of drag.

Nose down shot.

Maiden flight on an F50-4.

Open rocket said the optimum delay was 4.00 seconds and it was spot on.

Photo credit for the action shot goes to Air Command Water Rockets.

So I decided to build a mid power tube fin rocket designed for anything from an F composite up to a long burn H.

The body tube and fins would be made from cheap postal tubes with a long LOC 29mm motor mount tube. Aero Pack motor retainer and everything else 3d printed.

Nose cone ready for sanding after a long print.

Nose cone, centering rings and fin reinforcement rings.

Fin rings installed. Designed to protect the tube fins on landing.

Extra long motor mount tube. Helps with deployment and holds the chute up in the nose cone.

First dry fit.

Dry fit with nylon bolts to help align the tube fins. Rail button at the top of the photo. Needed a stand-off to clear the inside of the tube fin.

Paint scheme based on colours found in the shed.

Some stripes and a vinyl decal finish the job.

Plenty of drag.

Nose down shot.

Maiden flight on an F50-4.

Open rocket said the optimum delay was 4.00 seconds and it was spot on.

Photo credit for the action shot goes to Air Command Water Rockets.