Clivus

Well-Known Member

- Joined

- Apr 14, 2018

- Messages

- 71

- Reaction score

- 30

I hope tha t you guys don’t mind that I post the junk I make. Hopefully I will get better. I’ve started using Fusion 360. Very nice program with great education.

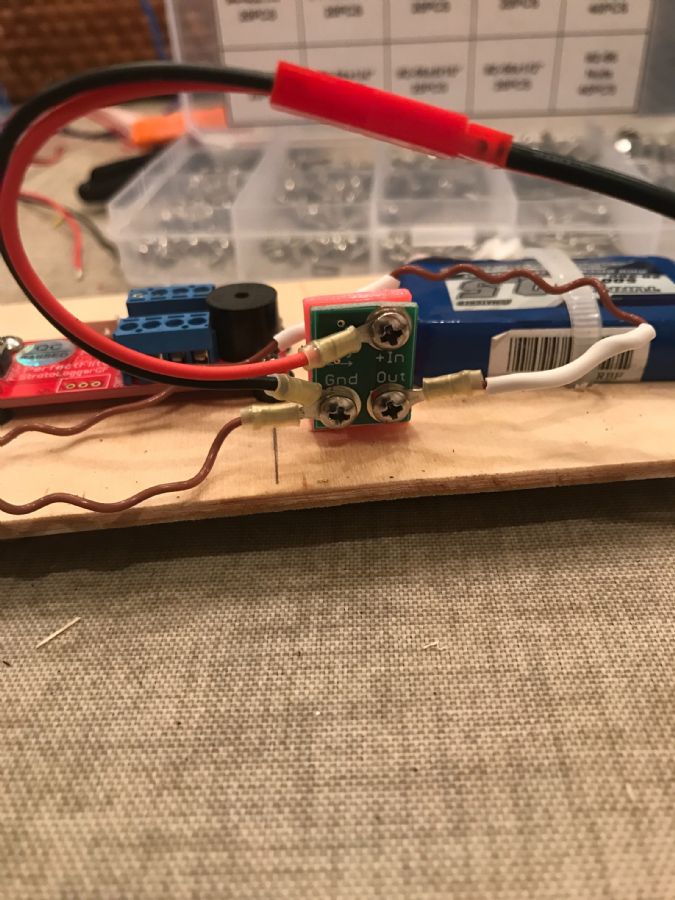

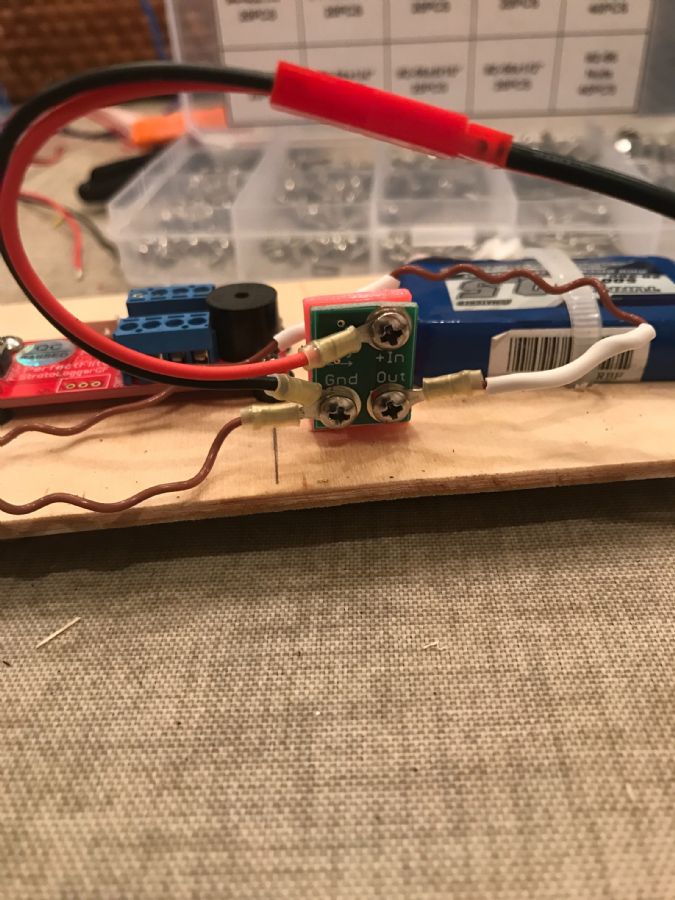

At Airfest, one of my big problem was the Kansas wind. I was using a pull pin switch and my charges fired 3 times while I was trying to assemble the rocket. I bought some Featherweight mag switches to make assembly a little easier. I made a little plate to mount the switches. I’m not sure if my OCD will allow the slight tilt that’s present after mounting. I hate my wiring too, but this was proof of concept

At Airfest, one of my big problem was the Kansas wind. I was using a pull pin switch and my charges fired 3 times while I was trying to assemble the rocket. I bought some Featherweight mag switches to make assembly a little easier. I made a little plate to mount the switches. I’m not sure if my OCD will allow the slight tilt that’s present after mounting. I hate my wiring too, but this was proof of concept