Planning my first AV Bay build now. This will be for a Punisher 3. Yes I've read the CJ build thread about a dozen times along with other builds as well. Very helpful.

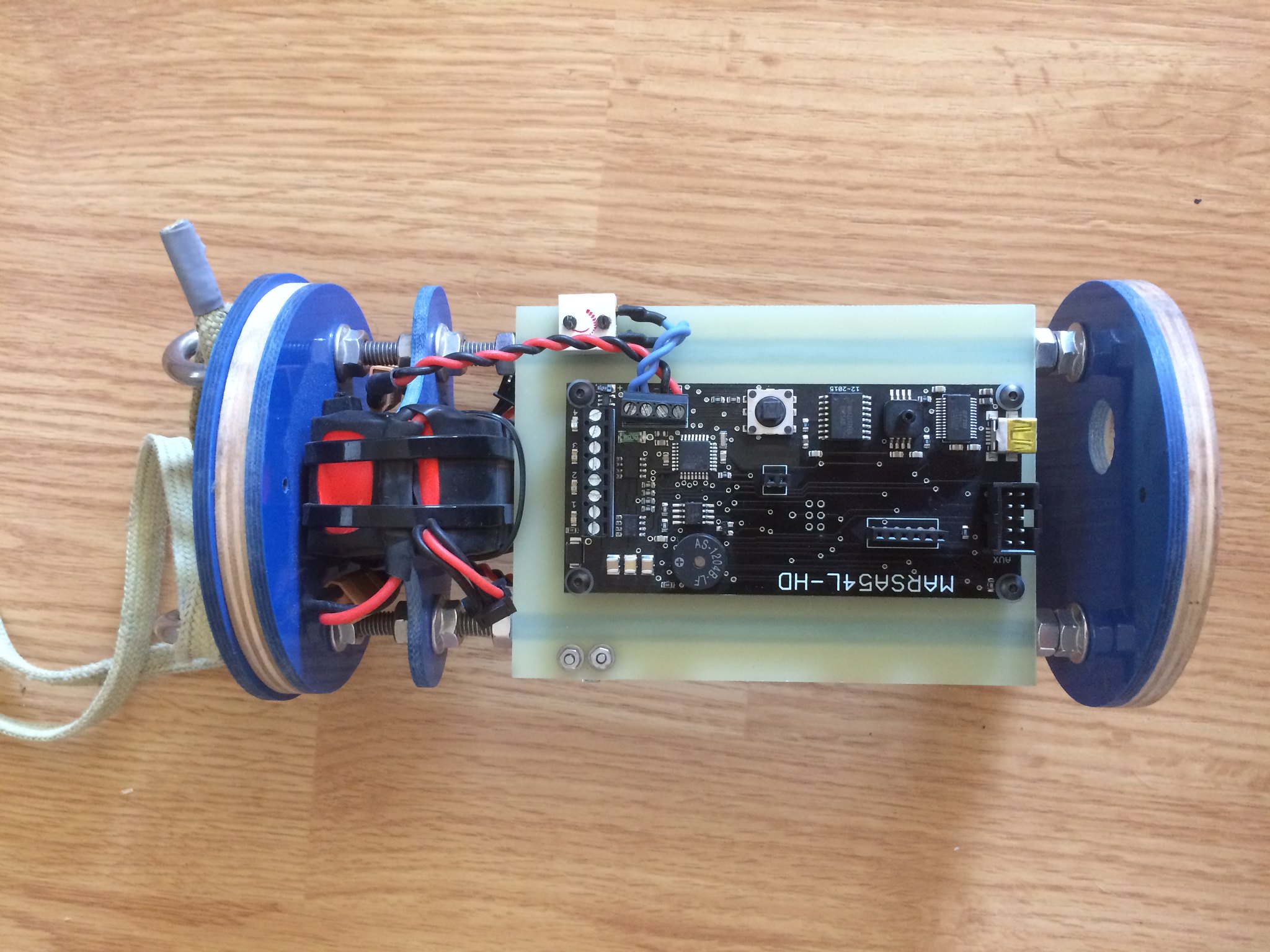

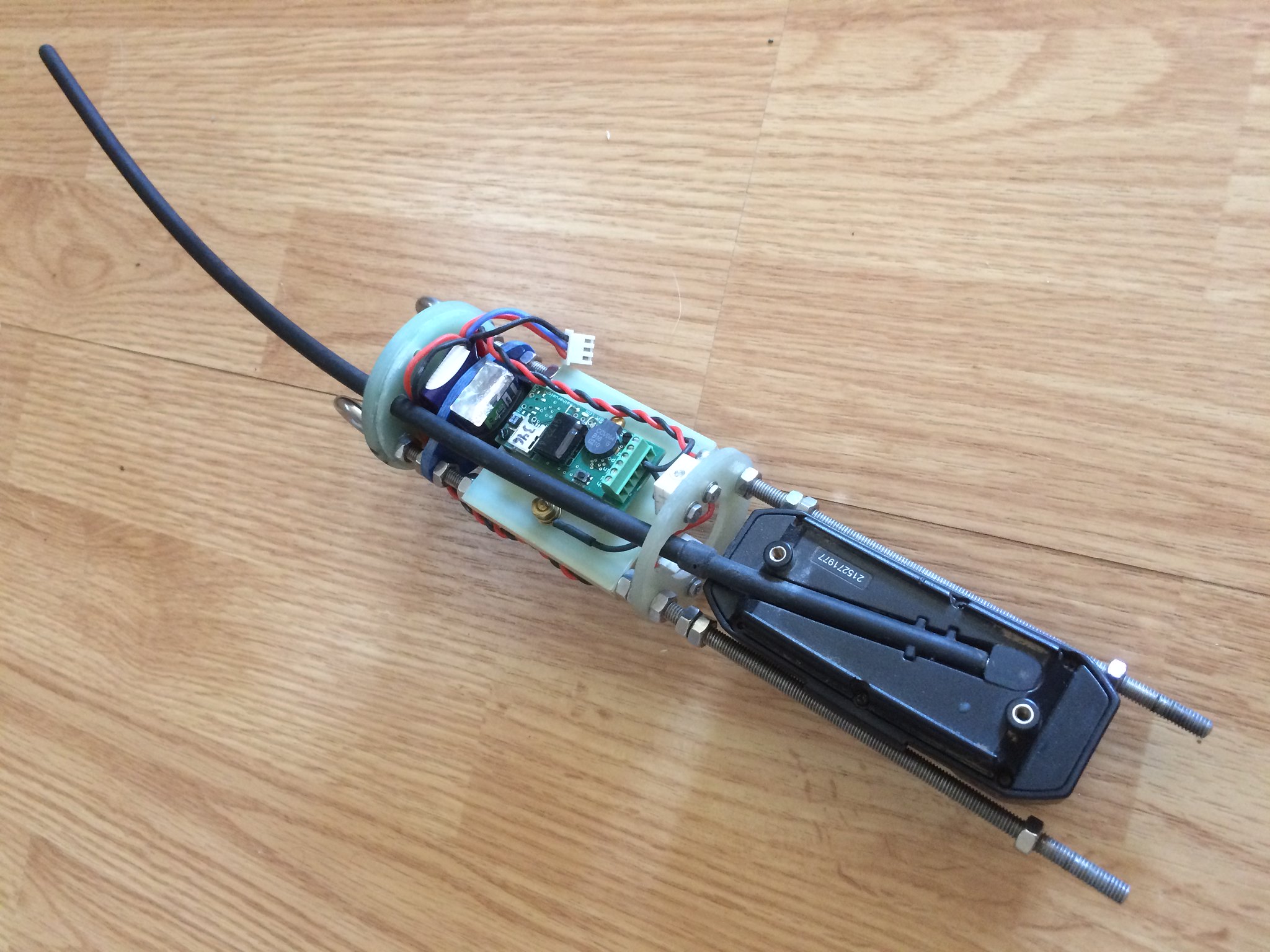

I'm looking for people's opinions on using one or two pieces of all thread in the AV bay. Obviously one is lighter and two would be stronger. Two would probably be just a few ounces more of hardware and on the top end where it's helpful. But is one strong enough? Seems to me the answer is yes. After my last build where I sided on the it's just a little more weight and a lot stronger but ended up with a tank I'm being more cautious. I'm leaning towards a single 1/4" rod down the center of the bay. Looking for reasons why this is a bad idea.

I'm looking for people's opinions on using one or two pieces of all thread in the AV bay. Obviously one is lighter and two would be stronger. Two would probably be just a few ounces more of hardware and on the top end where it's helpful. But is one strong enough? Seems to me the answer is yes. After my last build where I sided on the it's just a little more weight and a lot stronger but ended up with a tank I'm being more cautious. I'm leaning towards a single 1/4" rod down the center of the bay. Looking for reasons why this is a bad idea.