Cabernut

Well-Known Member

- Joined

- Oct 15, 2015

- Messages

- 1,384

- Reaction score

- 9

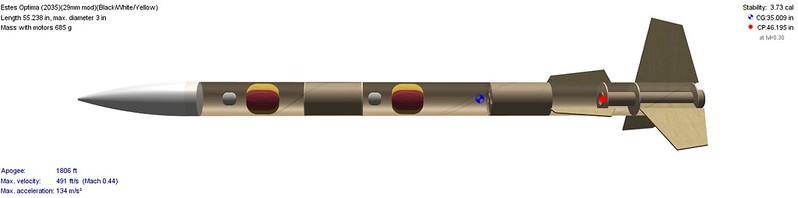

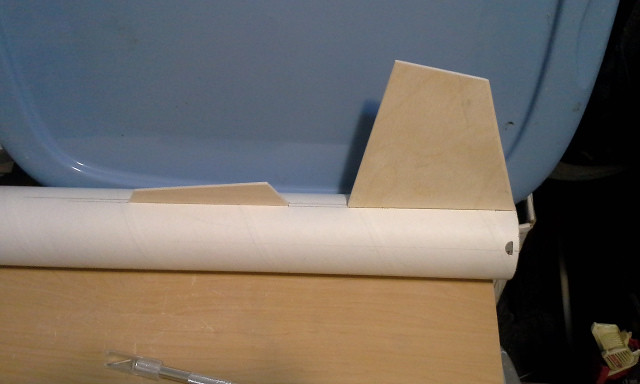

It hit me the other night what to do with the 3" mailer tubes I still have...

An Optima upscale! I barely remember the Optima from back in the day. I believe it was out of my(Mom's) price range at the time.

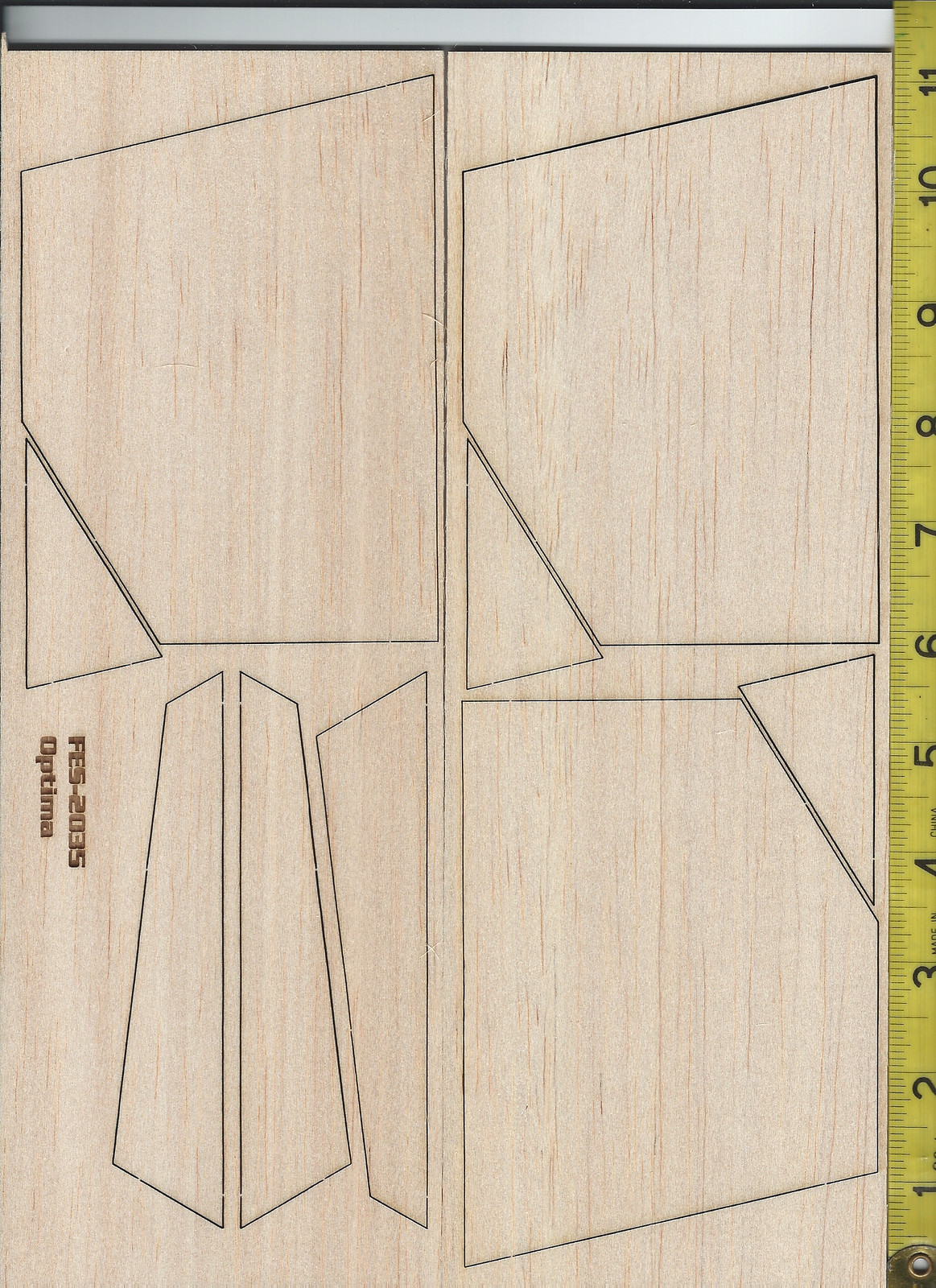

I'm thinking I'll do it PSII-style with 29mm MMT and TTW plywood fins. I could just buy a Scion and convert from there, but living on the north side of the border makes that a bit complicated to obtain.

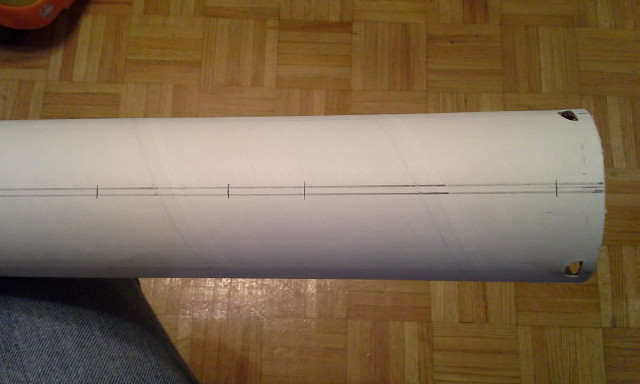

For the nose cone, I'll try my hand at fabricating a nose cone as these tubes are slightly wider than the usual 3" tube, they have a 3" I.D. (7.95cm OD, 7.62 ID) Could probably use a standard 3" tube as a coupler. This also means that The usual 3" nose cones would require some fiddling to fit and look right.

One thing I'm not sure of at this stage, while I'm tinkering with OR, is the stuffer tube.

Would this be necessary or beneficial with 29mm motors in a 3" tube?

Should I scale that part exactly, basically extending the 29mm tube up to where it would be scale-wise?

Any guidance/advice/comments are greatly appreciated.

An Optima upscale! I barely remember the Optima from back in the day. I believe it was out of my(Mom's) price range at the time.

I'm thinking I'll do it PSII-style with 29mm MMT and TTW plywood fins. I could just buy a Scion and convert from there, but living on the north side of the border makes that a bit complicated to obtain.

For the nose cone, I'll try my hand at fabricating a nose cone as these tubes are slightly wider than the usual 3" tube, they have a 3" I.D. (7.95cm OD, 7.62 ID) Could probably use a standard 3" tube as a coupler. This also means that The usual 3" nose cones would require some fiddling to fit and look right.

One thing I'm not sure of at this stage, while I'm tinkering with OR, is the stuffer tube.

Would this be necessary or beneficial with 29mm motors in a 3" tube?

Should I scale that part exactly, basically extending the 29mm tube up to where it would be scale-wise?

Any guidance/advice/comments are greatly appreciated.

Last edited:

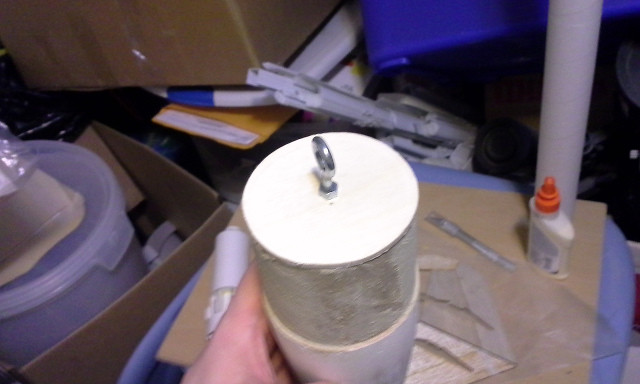

I guess I'm now committed to building in a baffle and attaching from there.

I guess I'm now committed to building in a baffle and attaching from there.