kjmccarx

Well-Known Member

- Joined

- Jul 1, 2013

- Messages

- 62

- Reaction score

- 0

I am just getting into HPR. I just build a rocket for my L1 attempt which I am hoping to do in a couple weeks. In the mean time I bought a tiny fiberglass kit (about 20" tall in total) at a launch down at Brother's Launch site in Oregon. Even though this is a little kit I am going all out (fiberglass, rail launch, aluminum retention ring, etc).

I have been teaching myself everything from day one, with the A engines and 7" parachutes, because none of my family or friends do this type of stuff, except for my girl friend who is learning along with me. I just found one person at my workplace who does rockets, but he does Os and Ps. To him anything under a K is trivial and because of that he is not too much help for getting me started :/

For card board rocket kits I've always used super glue, either 1-3 second, or 3-5 second depending on the purpose. I was thinking for the fiberglass kit that something such as J-B weld, or marine epoxy would be more appropriate. On the product page for the engine retainer they recommend J-B weld, but should I use that to secure the bulk heads, engine mount, and fins as well?

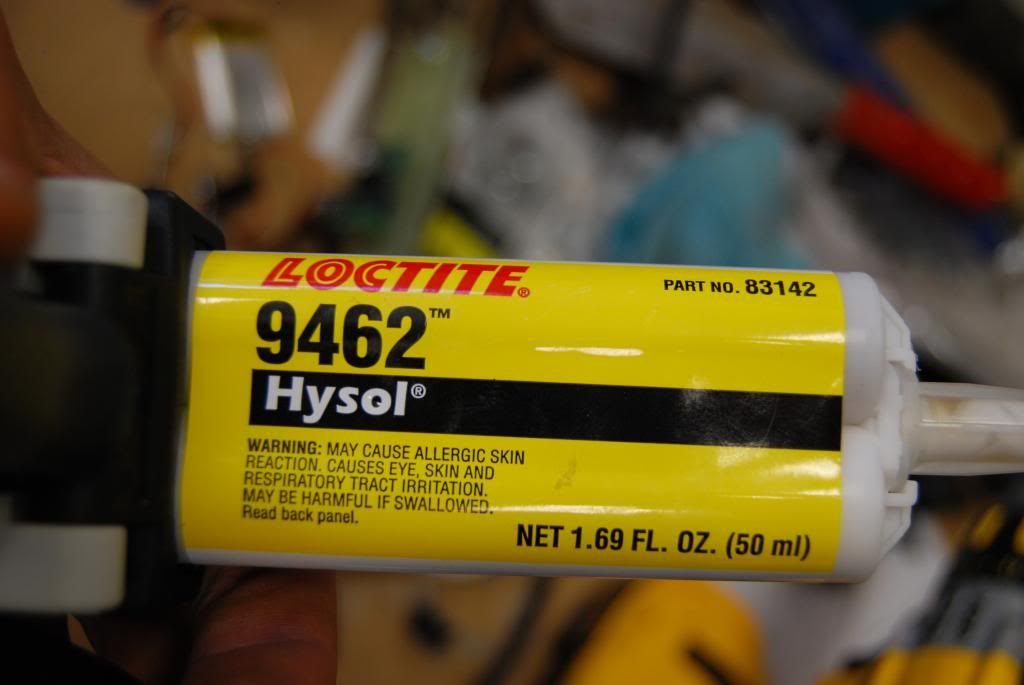

I know that marine epoxy is made for fiberglass so would something such as Locktite's marine epoxy work well for the fins and engine mount?

Those are just my thoughts, and I am very open to any other suggestions.

Thanks, guys!

I have been teaching myself everything from day one, with the A engines and 7" parachutes, because none of my family or friends do this type of stuff, except for my girl friend who is learning along with me. I just found one person at my workplace who does rockets, but he does Os and Ps. To him anything under a K is trivial and because of that he is not too much help for getting me started :/

For card board rocket kits I've always used super glue, either 1-3 second, or 3-5 second depending on the purpose. I was thinking for the fiberglass kit that something such as J-B weld, or marine epoxy would be more appropriate. On the product page for the engine retainer they recommend J-B weld, but should I use that to secure the bulk heads, engine mount, and fins as well?

I know that marine epoxy is made for fiberglass so would something such as Locktite's marine epoxy work well for the fins and engine mount?

Those are just my thoughts, and I am very open to any other suggestions.

Thanks, guys!