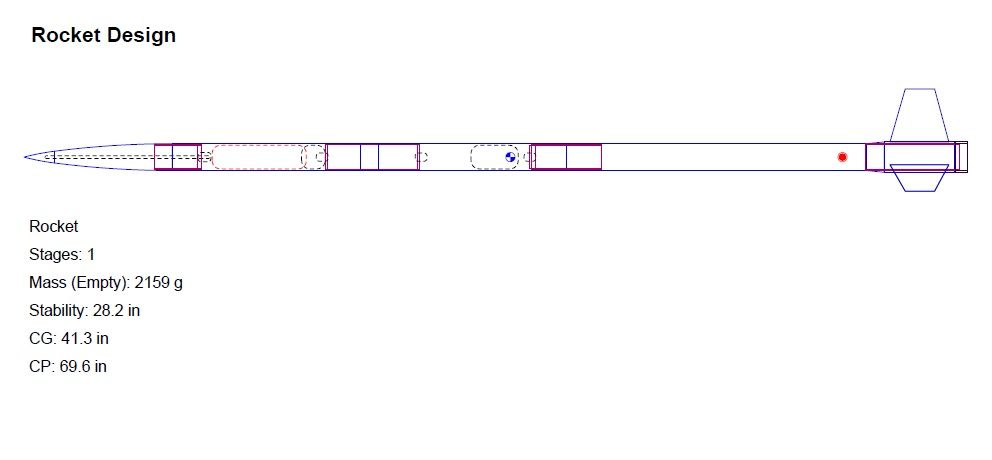

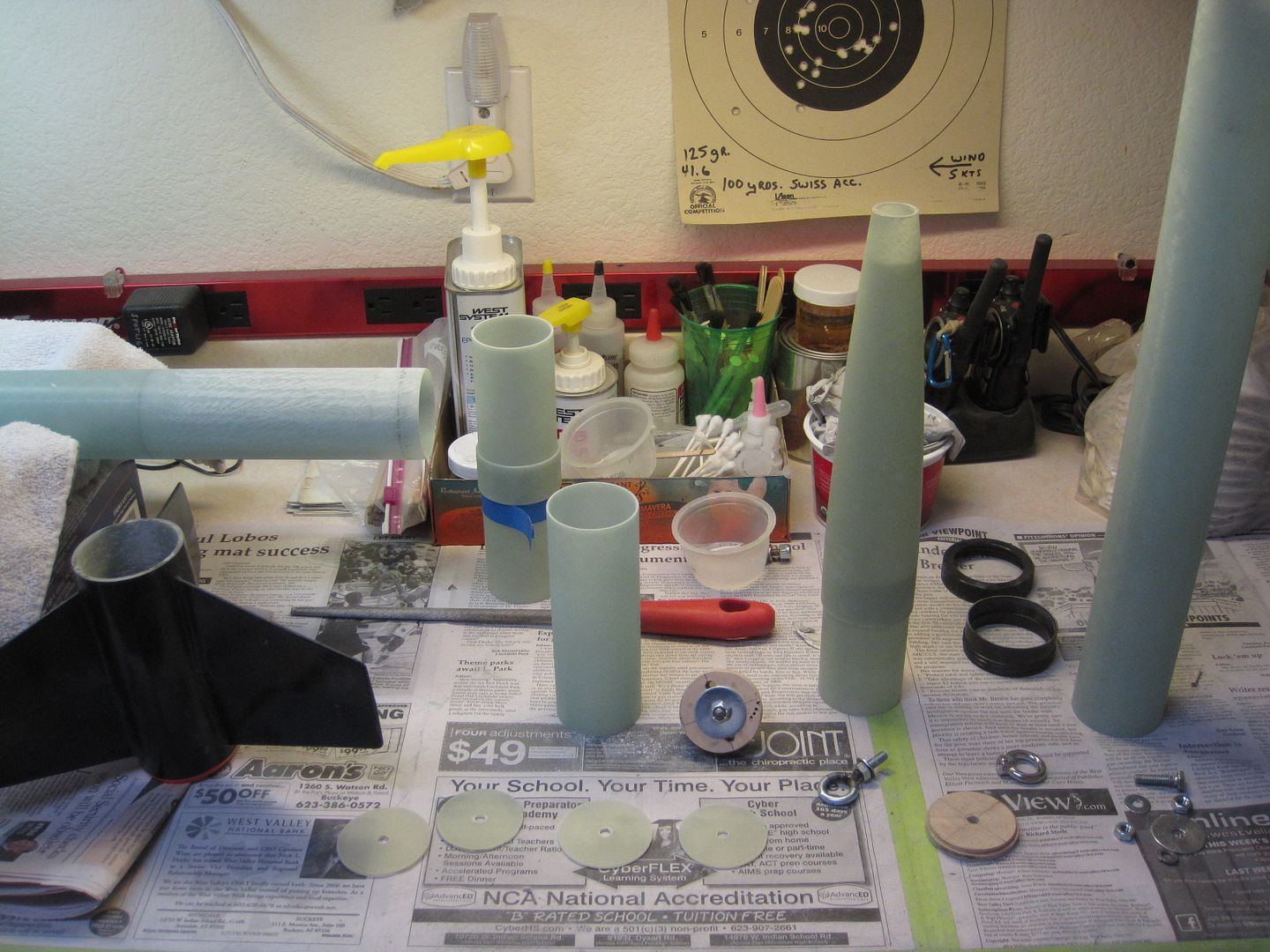

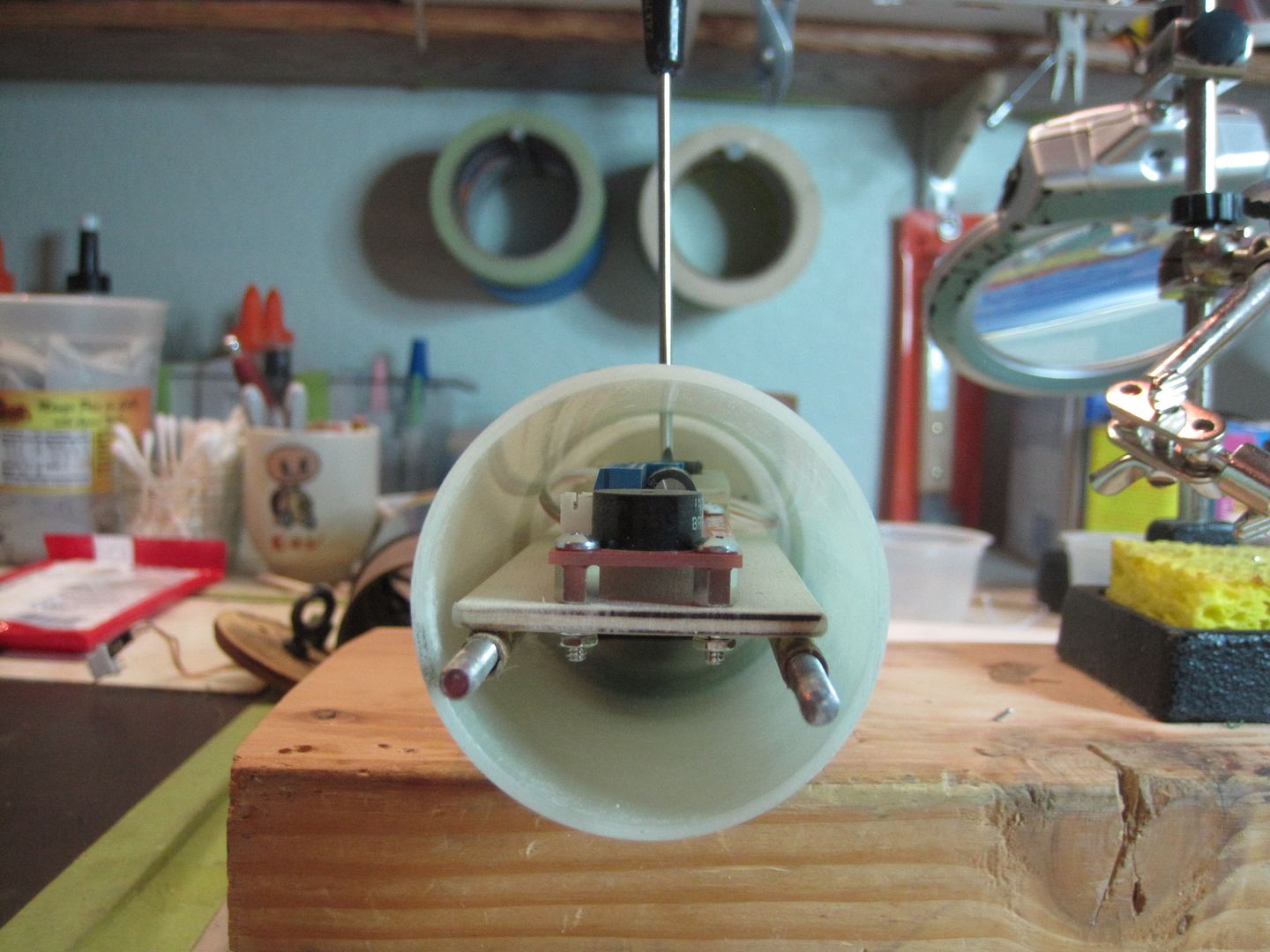

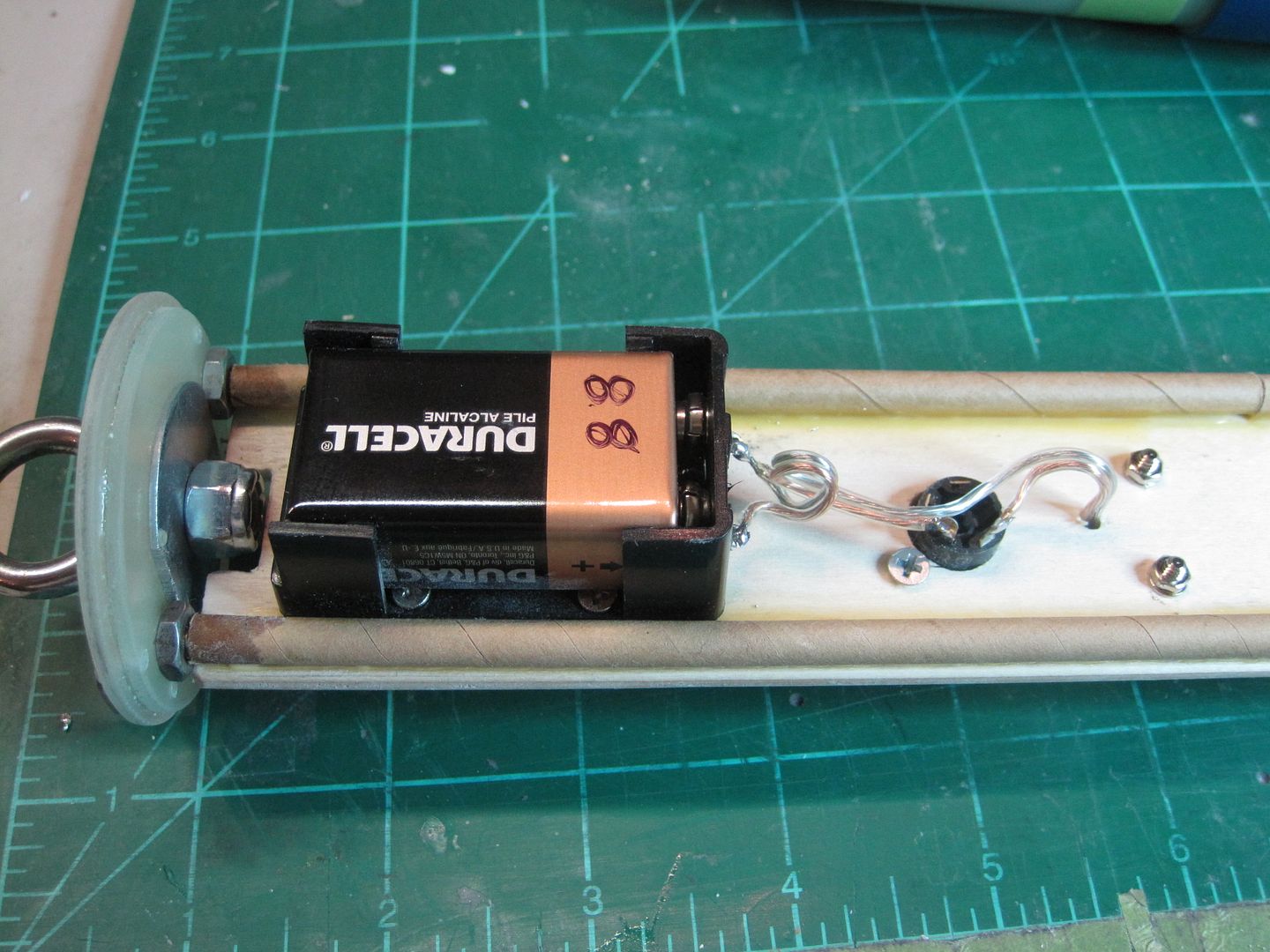

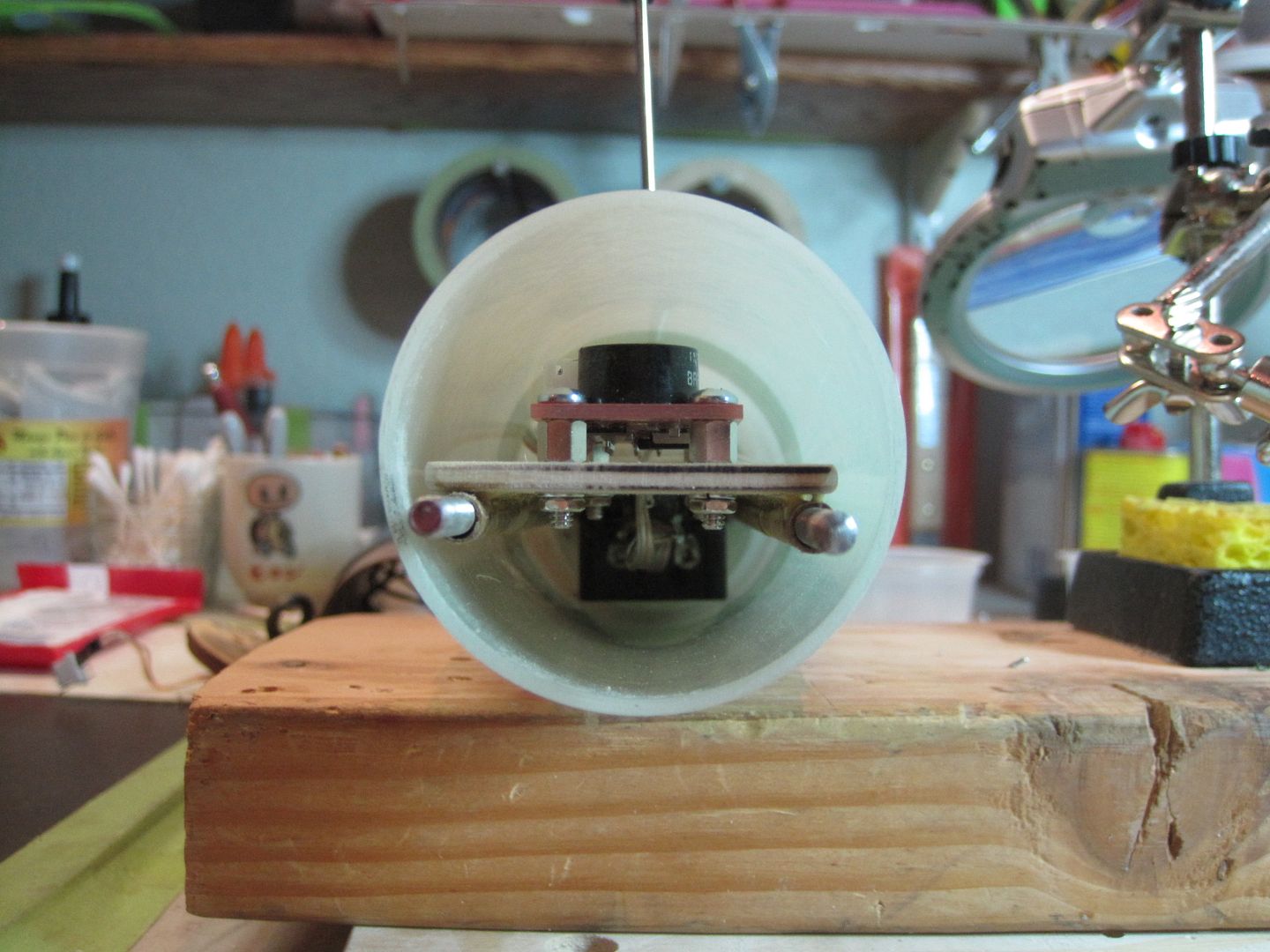

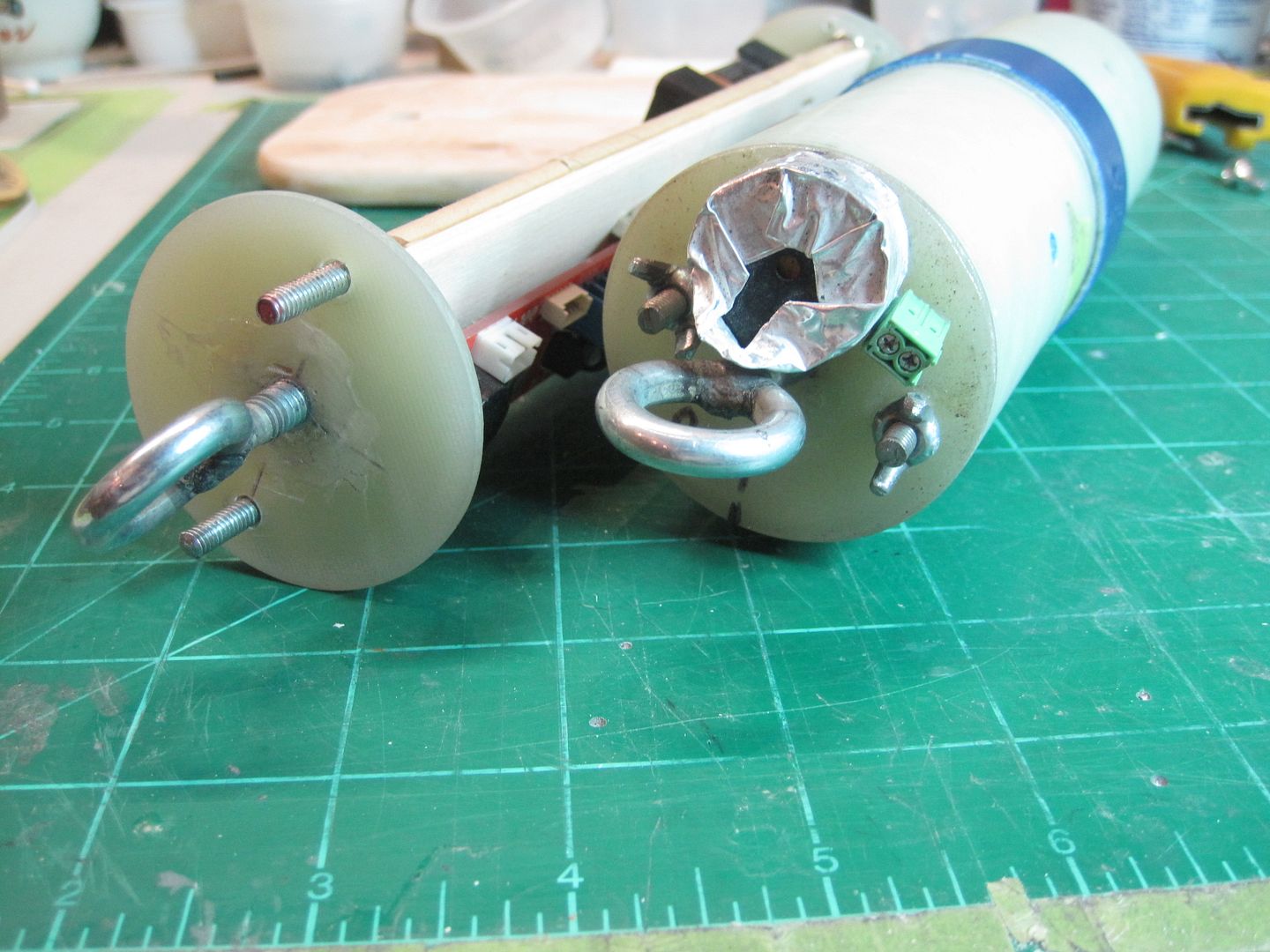

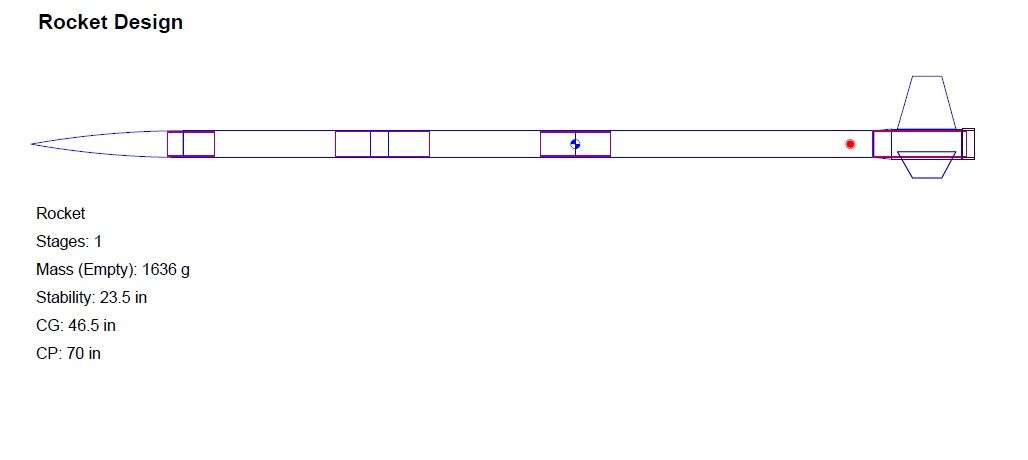

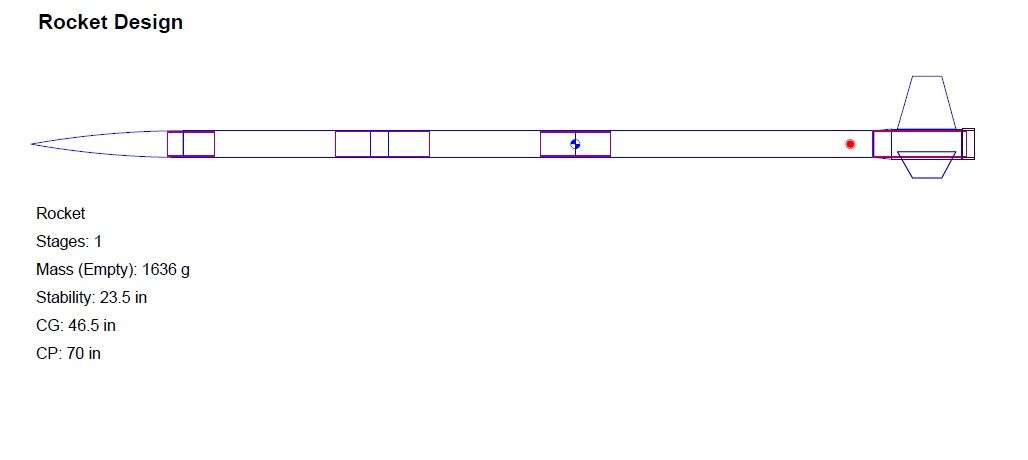

Started my next project yesterday, a 54mm minimum diameter fiberglass rocket I'm calling the bunny:

This rocket is a copy of my "Coppertop" rocket from this thread:

https://www.rocketryforum.com/showthread.php?44796-Estate-Sale-Coppertop-rocket

The main difference is the fiberglass components. I just finished my first fiberglass rocket, Wildman's Dark Star Jr.

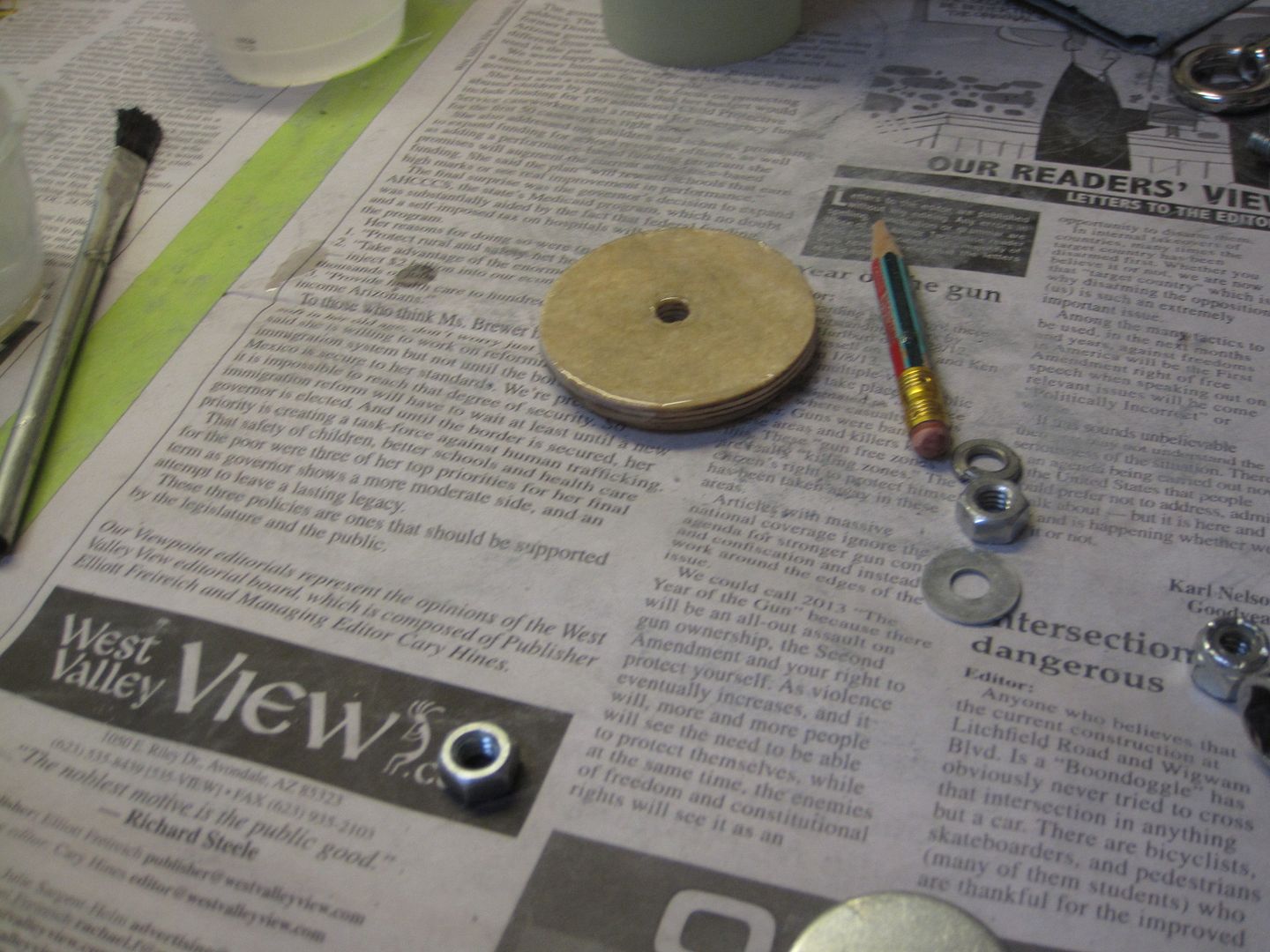

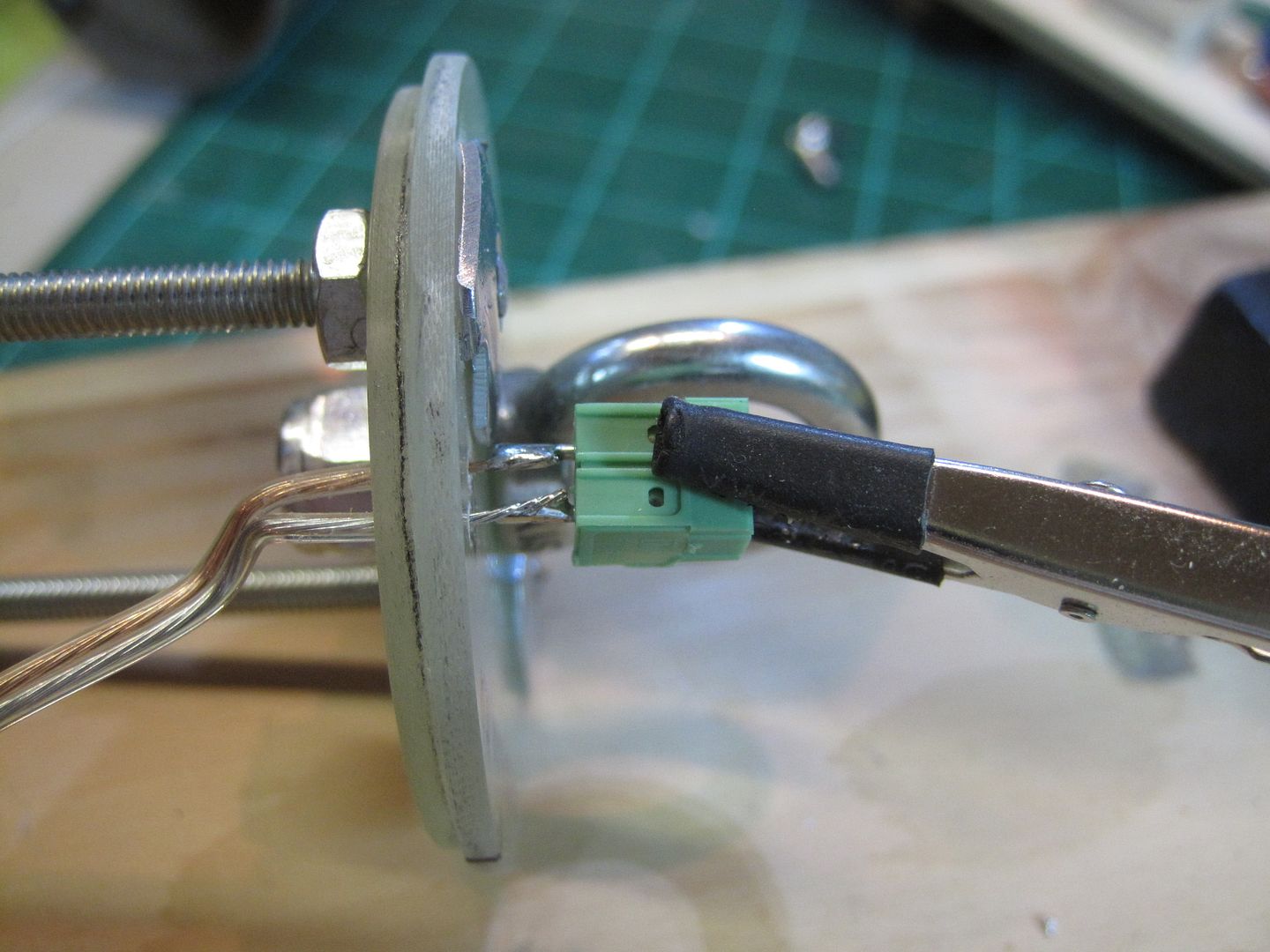

This one should be easier with the Acme fin can, but I'm still wondering about the correct adhesives for this build. Someone posted on another thread that West Systems 105 is a "laminating" epoxy for adding layers of fiberglass cloth, but I would like to use it structurally for bulkheads, couplers and to attach the fincan to the body tube. I have some milled fiberglass I add to the mix for these applications. Any problems with this idea?

I am just learning how to work with Open Rocket and would like some tips on how to add certain features, like the metal tip on my nosecone. Do I just add a mass object at the front, or can I form it separately?

Since this will be a very simple build, I'm not planning on making this a build thread, but I will be posting up some pic's shortly.

This rocket is a copy of my "Coppertop" rocket from this thread:

https://www.rocketryforum.com/showthread.php?44796-Estate-Sale-Coppertop-rocket

The main difference is the fiberglass components. I just finished my first fiberglass rocket, Wildman's Dark Star Jr.

This one should be easier with the Acme fin can, but I'm still wondering about the correct adhesives for this build. Someone posted on another thread that West Systems 105 is a "laminating" epoxy for adding layers of fiberglass cloth, but I would like to use it structurally for bulkheads, couplers and to attach the fincan to the body tube. I have some milled fiberglass I add to the mix for these applications. Any problems with this idea?

I am just learning how to work with Open Rocket and would like some tips on how to add certain features, like the metal tip on my nosecone. Do I just add a mass object at the front, or can I form it separately?

Since this will be a very simple build, I'm not planning on making this a build thread, but I will be posting up some pic's shortly.

Last edited: