First post! - Llama, welcome to this amazing forum. you will find the people here amazing and so willing to share so much information.

so - lets see what I can do for you here:

The rocket in this thread was just something in my head, I got the 2 nose cones, body tube, motor tube, centering rings and motor retainer from Rocketarium (love their selection of nose cones). The fins are G10 fiberglass purchased in sheets from EBAY).

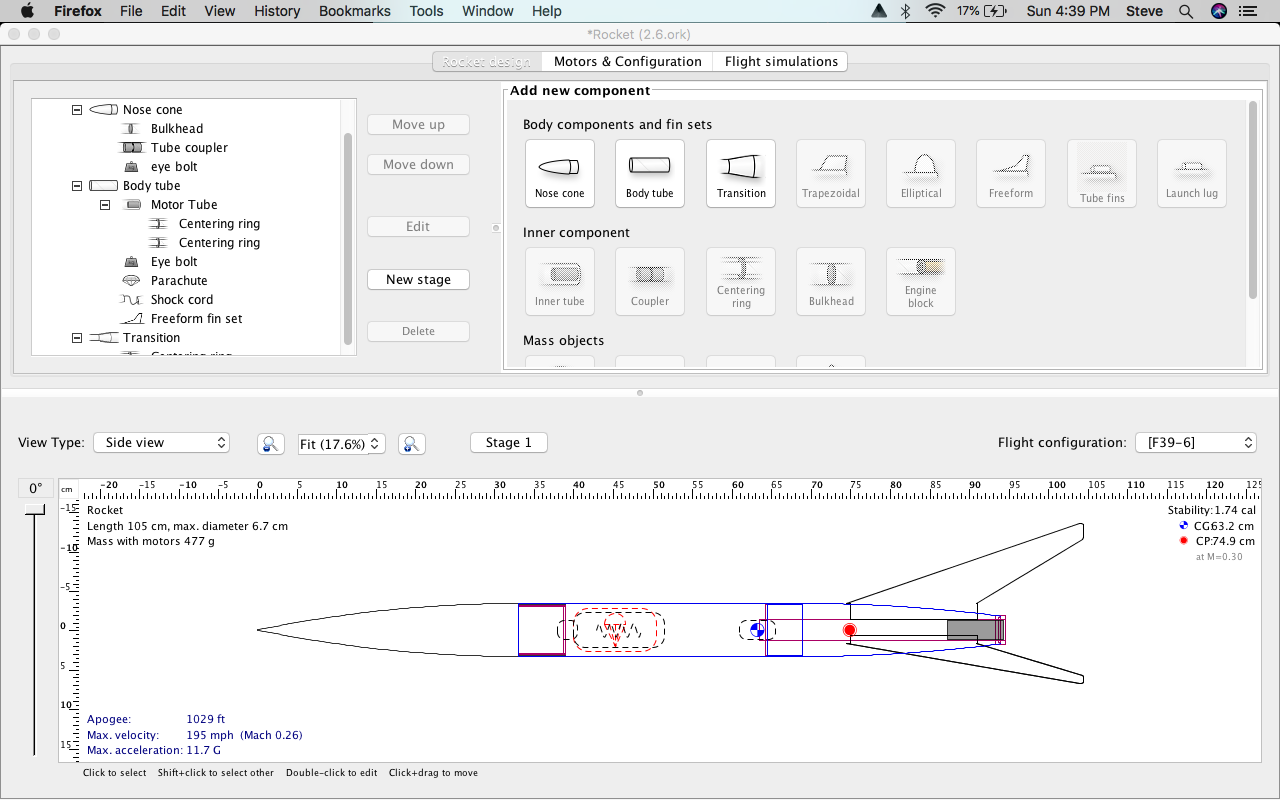

First, I model the idea in open rocket (if you don't have it, get it, it is free

).

The reason I do this is because once you model your body tube, tail cone and motor tube, you can create your fins on the body tube, then move them down to the position over the tail cone. Then create fin tabs that extend through the model to the motor tube. When this fin template is printed out (feature of Open Rocket) this gives you a template for the fins that is the shape and size you want with the material needed to reach the motor tube - has worked great for me.

Next, I mark the bottom edge of the body tube with the fin placement (3 or 4 fins), even if the fins will never touch the body tube.

I then insert the full nose cone (that will be cut off later to become a tail cone) into the body tube.

I then run a strip of tape from the each mark on the body tube to the center tip of the tail cone, draw that line with sharpie. Now I effectively have 3 or 4 perfectly spaced "cut" lines along the tail cone.

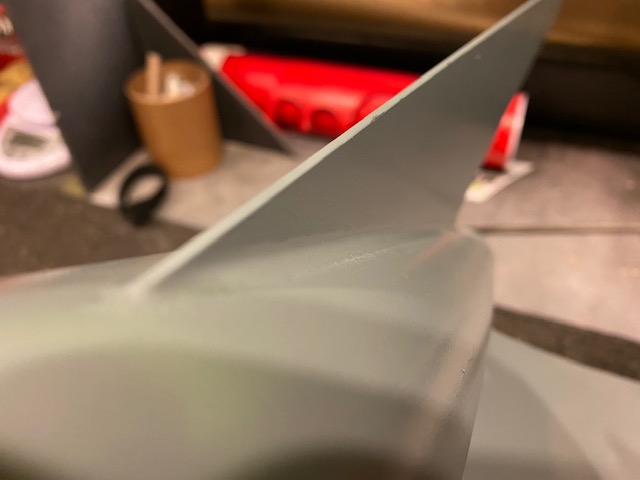

I then use one of 2 methods of actually cutting the slots:

method one: tape a flexible metal ruler on either side of the sharpie line, make multiple passes with a sharp exacto until i get through the plastic, move the ruler to the other side of the line, repeat. once both sides of the line are cut, i whittle the point in at each end of the slot to free the cut out piece, move to the next slot.

Method 2: - take a dremel with a cutoff wheel, put 2 cutoff wheels (with one or 2 small washers between them) on the dremel. You now have a dremel wheel that is as wide as your fin material. I then carefully free hand the cut with the sharpie line in between the 2 dremel cut wheels, works a champ.

you can then proceed to cut off the tip making it a tail cone

As for fin shapes, I play in open rocket or sketch out on paper, then create my template and cut them by hand

here are a few more examples of one off rockets that I have done with tail cones and the methods described here - all these fins were cut with a vice and a hack saw, the curves were done with a hand held coping saw and a drill (for the tight internal curves)