You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mega Rebel from Arkansas [Rocketarium] - Phase 1

- Thread starter Crawf56

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Crawf56

Pig Soooiiieee!!

Crawf56

Pig Soooiiieee!!

I still am not sure if this was a motor failure, or a construction failure.  (I am leaning toward construction.)

(I am leaning toward construction.)

Will be ordering another engine mount from Apogee. The rebuild begins....

Will be ordering another engine mount from Apogee. The rebuild begins....

- Joined

- Oct 8, 2016

- Messages

- 2,834

- Reaction score

- 1,211

I have flown enough "D" motors since the 70's to know that your CATO event was due to the motor. I "think" what happened is the nozzle of the D12-3 had one or more fractures. When the motor ignited the thrust forced the fracture(s) to expand and then fragment. With a portion of the nozzle gone, all the characteristics of the motor burn changed, causing accelerated rate of burn and a much larger then normal exhaust plume.

Alternatively, the fracture(s) could have been in the BP rather then the clay nozzle. But a fracture in the BP usually results in the motor case splitting open upon ignition.

Alternatively, the fracture(s) could have been in the BP rather then the clay nozzle. But a fracture in the BP usually results in the motor case splitting open upon ignition.

Crawf56

Pig Soooiiieee!!

Crawf56

Pig Soooiiieee!!

A tale of two glues....

For the plywood body, I used CA (per the instructions).

For the motor mount, I initially used Titebond II. Then, I went to Elmer's Glue-All. I did this because I have had problems (sometimes) with Titebond 'softening' cardboard tubes. And small amounts of Titebond actually drying rapidly, making it difficult to fit items in a tube.

The Glue-All is a little easier to work with, but it does not form a fillet like the Titebond. I also fear that the Glue-All does not hold as well as the Titebond.

So, I am going back to Titebond for the motor re-installation. Though I am also considering 30 minute epoxy.

For the plywood body, I used CA (per the instructions).

For the motor mount, I initially used Titebond II. Then, I went to Elmer's Glue-All. I did this because I have had problems (sometimes) with Titebond 'softening' cardboard tubes. And small amounts of Titebond actually drying rapidly, making it difficult to fit items in a tube.

The Glue-All is a little easier to work with, but it does not form a fillet like the Titebond. I also fear that the Glue-All does not hold as well as the Titebond.

So, I am going back to Titebond for the motor re-installation. Though I am also considering 30 minute epoxy.

Crawf56

Pig Soooiiieee!!

Built the Rebel John last year, get lots of comments at launches.

Mine flew great. I think i tacked it together with ca than tite bond fillets

Mine flew great. I think i tacked it together with ca than tite bond fillets

Last edited:

Crawf56

Pig Soooiiieee!!

Crawf56

Pig Soooiiieee!!

On 4/10/20, I had a fairly successful flight. Launched using an Aerotech E15W-4.

There was a slight north wind (less than 5 mph). My launch pad has a built in 4 degree tilt, and I had it tilted north.

At launch, the rocket went almost straight up! It arced over toward the north. The ejection charge popped, but the parachute did not make a canopy. The drag was enough for a successful landing, in tall grass.

When I checked the parachute, I saw that several of the shroud strings were slightly melted together. I thought I used enough recovery wadding, but I guess not.

There was a slight north wind (less than 5 mph). My launch pad has a built in 4 degree tilt, and I had it tilted north.

At launch, the rocket went almost straight up! It arced over toward the north. The ejection charge popped, but the parachute did not make a canopy. The drag was enough for a successful landing, in tall grass.

When I checked the parachute, I saw that several of the shroud strings were slightly melted together. I thought I used enough recovery wadding, but I guess not.

Congratulations on a successful flight.

- Joined

- Oct 8, 2016

- Messages

- 2,834

- Reaction score

- 1,211

Any landing that doesn't produce fragments is a good one. Congrats.

- Joined

- Aug 27, 2011

- Messages

- 11,598

- Reaction score

- 6,223

Not exactly a review I am guessing the manufacturer is looking for (but funny!)Any landing that doesn't produce fragments is a good one. Congrats.

Crawf56

Pig Soooiiieee!!

I want to emphasize that the problems encountered were not the fault of the rocket design or manufacturer.

- Had an old Estes motor possibly misfire. Had been out of the package, in a ziplock bag, for at least a year.

- I think I may have used the wrong glue to install the motor mount.

- I need to make sure I am putting enough Recovery Wadding in the rocket. I believe I put in 8-10 squares, and I should have put in 12.

I've flown mine 3 times and never had good "as-planned" launch (flights on RocketReviews).

First one was on a C11-3 and the chute didn't open and the stiff kevlar shield also seemed to be an issue (note it was winter). Next time on D12, the ejection blew the nose completely off and the body came down chuteless while the nose with open chute drifted FAR away into a tree (recovered)...thin shock cord not up to the weight of the nose seemed to be an issue. Last flight with heavier shock cord had another parawad...body tube just seems too small to hold a chute large enough for this HEAVY rocket imo. I plan to eventually "successfully" launch and recover it one day. =P

Great kit and awesome launching up tho...getting it down nicely is another matter for me.

*NOTE* I originally got this kit with quasi-similar plans...I was going to cover it with stretchy book cover material after I got it flying well...still working on that. ;-)

First one was on a C11-3 and the chute didn't open and the stiff kevlar shield also seemed to be an issue (note it was winter). Next time on D12, the ejection blew the nose completely off and the body came down chuteless while the nose with open chute drifted FAR away into a tree (recovered)...thin shock cord not up to the weight of the nose seemed to be an issue. Last flight with heavier shock cord had another parawad...body tube just seems too small to hold a chute large enough for this HEAVY rocket imo. I plan to eventually "successfully" launch and recover it one day. =P

Great kit and awesome launching up tho...getting it down nicely is another matter for me.

*NOTE* I originally got this kit with quasi-similar plans...I was going to cover it with stretchy book cover material after I got it flying well...still working on that. ;-)

- Joined

- Jan 7, 2019

- Messages

- 1,353

- Reaction score

- 1,019

I've switched to dog barf on everything. one piece of wadding at the bottom covering the engine mount hole, then dog barf. A bail at Lowe's or Home Depot will set you back less than 10 bucks and literally last a lifetime. The only hard part is you have to store it somewhere.On 4/10/20, I had a fairly successful flight. Launched using an Aerotech E15W-4.

There was a slight north wind (less than 5 mph). My launch pad has a built in 4 degree tilt, and I had it tilted north.

At launch, the rocket went almost straight up! It arced over toward the north. The ejection charge popped, but the parachute did not make a canopy. The drag was enough for a successful landing, in tall grass.

When I checked the parachute, I saw that several of the shroud strings were slightly melted together. I thought I used enough recovery wadding, but I guess not.

View attachment 411996

- Joined

- Jan 7, 2019

- Messages

- 1,353

- Reaction score

- 1,019

Is the original shock cord elastic? Bleck. I've switched to kevlar for everything, including LPR. To avoid zippers I use shrink wrap tubing on the cord at the top of the airframe (BEFORE I attach the shock cord to the nose cone), built up in several layers to provide plenty of cushion. No more broken shock cords.I've flown mine 3 times and never had good "as-planned" launch (flights on RocketReviews).

First one was on a C11-3 and the chute didn't open and the stiff kevlar shield also seemed to be an issue (note it was winter). Next time on D12, the ejection blew the nose completely off and the body came down chuteless while the nose with open chute drifted FAR away into a tree (recovered)...thin shock cord not up to the weight of the nose seemed to be an issue. Last flight with heavier shock cord had another parawad...body tube just seems too small to hold a chute large enough for this HEAVY rocket imo. I plan to eventually "successfully" launch and recover it one day. =P

Great kit and awesome launching up tho...getting it down nicely is another matter for me.

*NOTE* I originally got this kit with quasi-similar plans...I was going to cover it with stretchy book cover material after I got it flying well...still working on that. ;-)

Is the original shock cord elastic?

Yes, the original was this super-wimpy linguine elastic cord...maybe 1/8"? I was very leery of using the original cord and such, but my general rule is to assume the designer is right first before I start improving.

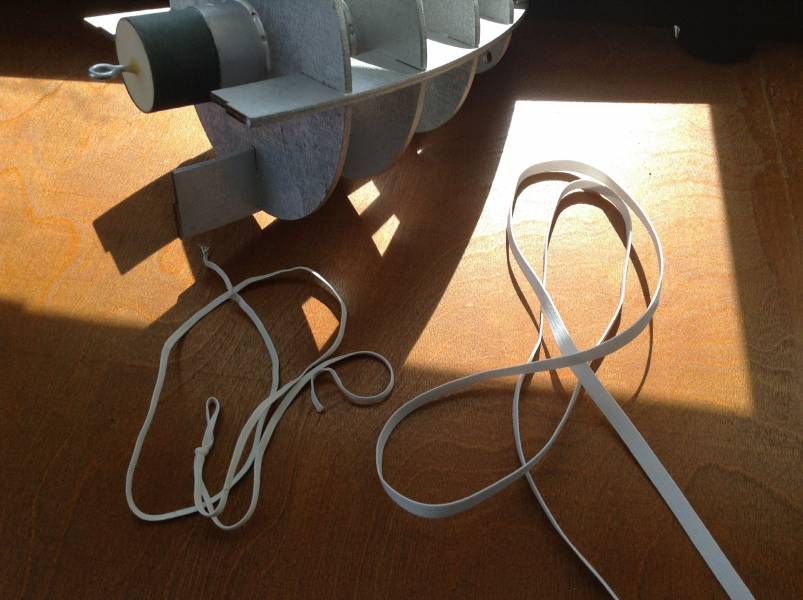

However the cord did break as I suspected, so here's a pic of the original next to the thicker cord I was replacing it with:

I do like your idea of kevlar replacement, but I don't have exp with that and these are very heavy parts imo. How long and what type of kevlar did you use? Interested in trying that in the future.

EDIT: My kit is from ~2015, so it looks like the more recent kit has a stronger round shock cord vs. the thin flat elastic cord in my kit.

Last edited:

BTW - I had some concerns with covering this rocket because I'm not sure how the "fishbone" profile affects the CP and covering over it would likely move the CP somewhat unpredictably. I wanted to us the stretch "breathable" book-cover covering to allow some air to still get through as a second step so I hopefully wouldn't change the aerodynamics radically. Still, this rocket seemed heavy and I couldn't get it to reliably have a good launch and recovery, so I shelved the plans for a while. Also I'd prefer to do it on a smaller scale first.

Personally I think this kit would be much better with a transition to a larger forward chute bt section (egg-lofter? lol). Seems to be room for that and this would allow better chute deployment and a bigger chute.

Personally I think this kit would be much better with a transition to a larger forward chute bt section (egg-lofter? lol). Seems to be room for that and this would allow better chute deployment and a bigger chute.

Crawf56

Pig Soooiiieee!!

I've flown mine 3 times and never had good "as-planned" launch (flights on RocketReviews).

First one was on a C11-3 and the chute didn't open and the stiff kevlar shield also seemed to be an issue (note it was winter). Next time on D12, the ejection blew the nose completely off and the body came down chuteless while the nose with open chute drifted FAR away into a tree (recovered)...thin shock cord not up to the weight of the nose seemed to be an issue. Last flight with heavier shock cord had another parawad...body tube just seems too small to hold a chute large enough for this HEAVY rocket imo. I plan to eventually "successfully" launch and recover it one day. =P

Great kit and awesome launching up tho...getting it down nicely is another matter for me.

*NOTE* I originally got this kit with quasi-similar plans...I was going to cover it with stretchy book cover material after I got it flying well...still working on that. ;-)

In my Mega Rebel kit, it states that the minimum motor is a D12-3, and it should only be flown on "calm days". Otherwise, the only recommended motors are E-size.

Crawf56

Pig Soooiiieee!!

Yes, the original was this super-wimpy linguine elastic cord...maybe 1/8"? I was very leery of using the original cord and such, but my general rule is to assume the designer is right first before I start improving.

However the cord did break as I suspected, so here's a pic of the original next to the thicker cord I was replacing it with:

I do like your idea of kevlar replacement, but I don't have exp with that and these are very heavy parts imo. How long and what type of kevlar did you use? Interested in trying that in the future.

EDIT: My kit is from ~2015, so it looks like the more recent kit has a stronger round shock cord vs. the thin flat elastic cord in my kit.

My shock chord was somewhat fried during the first CATO flight. I am considering replacing it with elastic/chord that attaches to the frame, outside of the tube.

Crawf56

Pig Soooiiieee!!

BTW - I had some concerns with covering this rocket because I'm not sure how the "fishbone" profile affects the CP and covering over it would likely move the CP somewhat unpredictably. I wanted to us the stretch "breathable" book-cover covering to allow some air to still get through as a second step so I hopefully wouldn't change the aerodynamics radically. Still, this rocket seemed heavy and I couldn't get it to reliably have a good launch and recovery, so I shelved the plans for a while. Also I'd prefer to do it on a smaller scale first.

Personally I think this kit would be much better with a transition to a larger forward chute bt section (egg-lofter? lol). Seems to be room for that and this would allow better chute deployment and a bigger chute.

This is why I measured the CG prior to covering, and I will do the old 'string test' for stability.

I do plan to start another thread on covering the Mega Rebel.

- Joined

- Jan 7, 2019

- Messages

- 1,353

- Reaction score

- 1,019

I've put this on my wish list and find the comments helpful. Given the noted challenges I'll be making mods when I get to it. The shock cord will be light kevlar. If the 15" chute is tight for the tube, I would sim it with two 12" chutes and might let the two halves come down separately. If an E engine is a minimum for a decent flight, then no Estes BP engines, Aerotech single use E and above only.

Similar threads

- Replies

- 1

- Views

- 207

- Replies

- 49

- Views

- 2K

- Replies

- 4

- Views

- 446