You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Locating dowel quick tutorial

- Thread starter Wallace

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

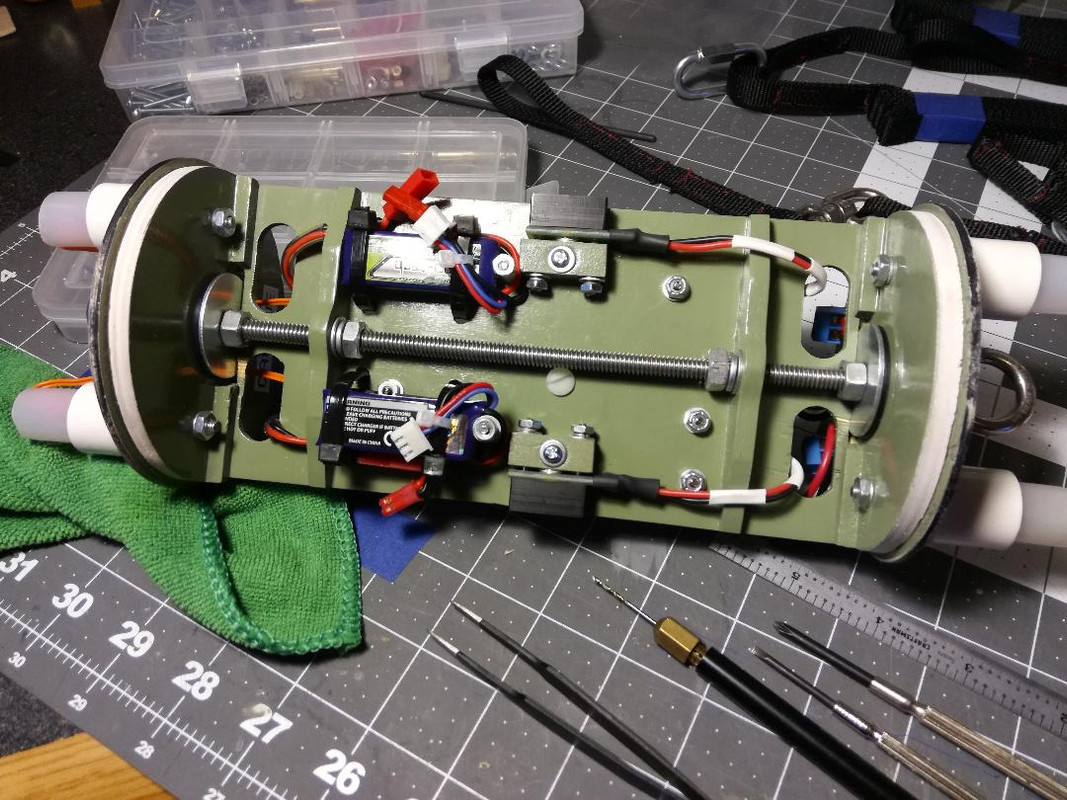

It literally takes a few minutes to accomplish but saves tons of time later, especially in the field under less than perfect conditions. This is my favorite way to do it because it's simple andt akes very little time. Makes assembling av bays and whatnot absolutely repeatable without having to see hash marks. I prefer to use .125 aluminum welding rod because I always have it on hand. Could just as easily have been a skewer,stick, bone etc. etc. etc. I like to use multiples on double ended deals, helps avoid

backward oops, holy crap I'm blind and or stupid moments .

backward oops, holy crap I'm blind and or stupid moments .

backward oops, holy crap I'm blind and or stupid moments .

backward oops, holy crap I'm blind and or stupid moments .

Last edited:

I just eyeball a small pilot hole and follow it up with an 1/8" drill. Before I even got out any tools, I mixed up a small batch of Rocketpoxy, drilled the holes, inserted and cut off the rod with a hobby saw then roughed 'em in with a file. All complete before the glue set up. Do yourself a huge favor and use locators whenever possible.

Curtis Enlow

Well-Known Member

That's a great idea.

I have a light, single-rod av bay and the sled goes into slots on the bulkhead, but once the shoulder is inside the coupler you can't see to align the coupler with the sled.

I'm going to use this next time.

I have a light, single-rod av bay and the sled goes into slots on the bulkhead, but once the shoulder is inside the coupler you can't see to align the coupler with the sled.

I'm going to use this next time.

Good question. I often wonder myself...May I ask what you are locating?

- Joined

- Jul 15, 2015

- Messages

- 3,958

- Reaction score

- 2,720

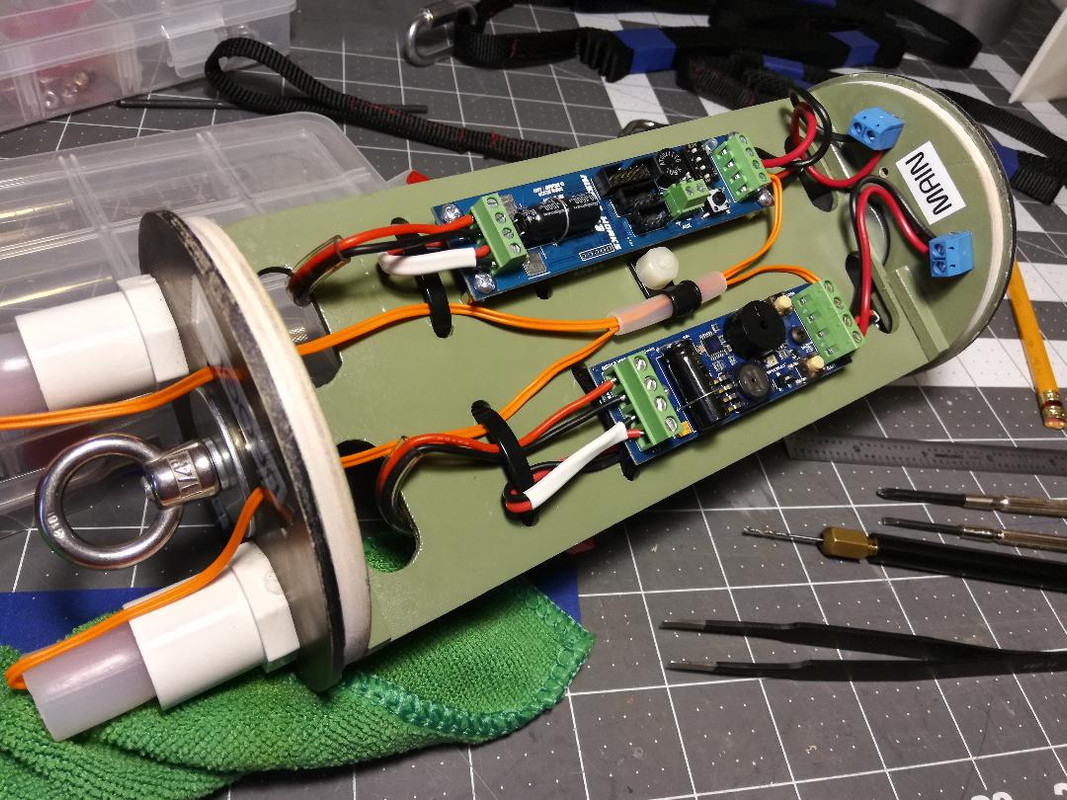

He's keyed the "main" and "drogue" lids on the av bay differently to prevent mis-assembly.

Similar to the method that is also used to align the av bay in the rocket.

Similar to the method that is also used to align the av bay in the rocket.

Thank You. Not sure if it applies to any of you but all my parts have a tendency to fit best in one spot, so that's where I key 'em. And then there's always the whole mis-assembly thing, not that I've ever done thatHe's keyed the "main" and "drogue" lids on the av bay differently to prevent mis-assembly. Similar to the method that is also used to align the av bay in the rocket.

Pics? Sounds like a great idea.That's a great idea.

I have a light, single-rod av bay and the sled goes into slots on the bulkhead, but once the shoulder is inside the coupler you can't see to align the coupler with the sled.

I'm going to use this next time.

Curtis Enlow

Well-Known Member

Pics? Sounds like a great idea.

Here is an example pic. You can see the locators on the interior side of the bulkhead that form a slot to keep the sled from rotating or torquing, something a single-rod assembly will tend to do otherwise. The single aluminum all-thread (www.fastenal.com) is significantly lighter than steel, and certainly strong enough to transfer the longitudinal deployment loads of a smaller L1 ship. The entire dual redundancy coupler/sled/electronics assembly, short only the actual black powder charges, comes in at about 552g, if I remember correctly.

Your locating pins would be a huge help during assembly, as it can take a bit of fiddling locating everything together once in the coupler tube. There are fabrication process pics & descriptions on my build thread: https://www.rocketryforum.com/threads/my-loc-iv-build-thread.152141/

Wow, that's clean work, thanks for sharing that. I doubt I'll ever come close to anything that nice. I do have a few single allthread bays with pull pin switches that demand precise indexing so I was basically forced to come up with something. After fighting/forcing/mis-aligning,tic marks, paint lines etc. Well... I certainly didn't invent it but I did "dial it in" to where it is stupidly simple and takes so little time and effort to accomplish that it wouldn't make sense to not do it. Hope this helps someone somewhere at sometime..

Curtis Enlow

Well-Known Member

Thanks  It actually wasn't all that difficult; I actually did a lot of the designing on-the-fly.

It actually wasn't all that difficult; I actually did a lot of the designing on-the-fly.

I like the idea of pull-pin switching, but I think I would have to design in some sort of keying to avoid inadvertently arming the charges.

I like the idea of pull-pin switching, but I think I would have to design in some sort of keying to avoid inadvertently arming the charges.

Thanks for posting the tutorial. This is a really useful idea that I use on all my HPR. I usually use steel tooling pins (I have them on-hand) for the larger rockets, and carbon fiber rod from the local hobby shop for smaller (<=54mm) rockets. Takes all the guesswork out of lining up those fastener holes  .

.

Things we normally take for granted might not always be obvious to others. It occurred to me that as long as I was doing it I might just as well spend an extra minute and try to help. My methods are usually geared more toward expedience than cosmetic so take that into account. I've learned thousands of things by simply watching/viewing/reading so I feel good if even one person gets something out of it. Open source would be the term?

- Joined

- Jul 15, 2015

- Messages

- 3,958

- Reaction score

- 2,720

I've done something like that many, many times for the av bay, but never the lids.

Always the lids.. Always...I've done something like that many, many times for the av bay, but never the lids.

blackjack2564

Crazy Jim's Gone Banana's

Yeeeuup...I just messed up last weekend and stripped all shroud lines but 1 from a 60 Spherachute.

Put the sled & lids in av-bay backwards so my main popped at top...except it was a rainbow at high speed Wowzzarr....

Av-bay went on correctly, just not the lids...lol

PS rocket was fine it's 112th flight since 2003!

Put the sled & lids in av-bay backwards so my main popped at top...except it was a rainbow at high speed Wowzzarr....

Av-bay went on correctly, just not the lids...lol

PS rocket was fine it's 112th flight since 2003!

"These guys enjoy what they do, and get the excitement for various projects out there to a lot of people like myself. That's the 'positive that can come from it'. An open source project is only as good as the group of people that contribute to it, and that has to be continually fed with new ideas and talent or it fades away"... Again, not my quote...

Similar threads

- Replies

- 13

- Views

- 860

- Replies

- 31

- Views

- 2K

- Replies

- 2

- Views

- 542