Curtis Enlow

Well-Known Member

Hey all,

I am wondering how you approach building in the option to add/remove nose weight for rockets where your CG may vary due to using a wide variety of motors and/or motor tube adapters or standard vs. dual deployment/e-bay recovery modes?

I have done the ubiquitous nosecone mod but have not epoxied it into place yet. I have not finished the rocket, so I do not have a final weight to start plugging in numbers. An additional complicating factor is that - providing the weight works out to 1500g. or under - I would like to be able to fly it at the local field on smaller 29mm reloads, but would like to build an HP option with an electronics bay coupler and extended BT to obtain my L1 and use HP 38mm loads.

It may well be that with the coupler and larger motors I might not even need the option for nose weight adjustment, but I would like to have the option if needed.

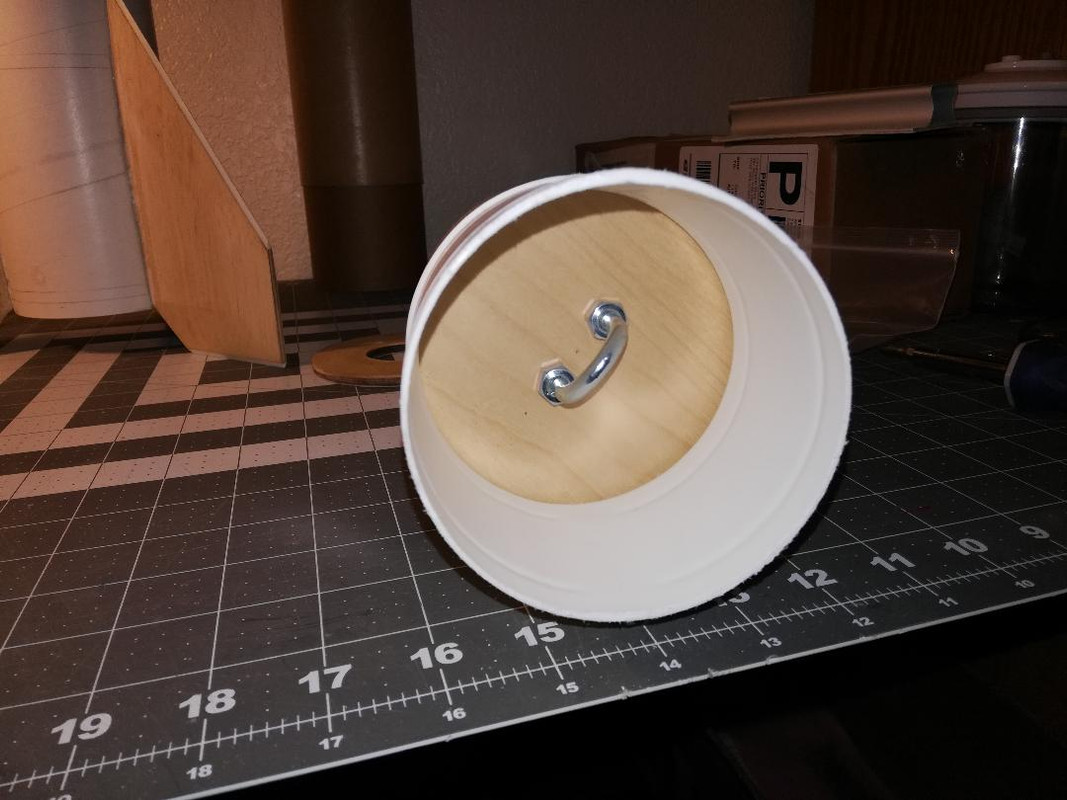

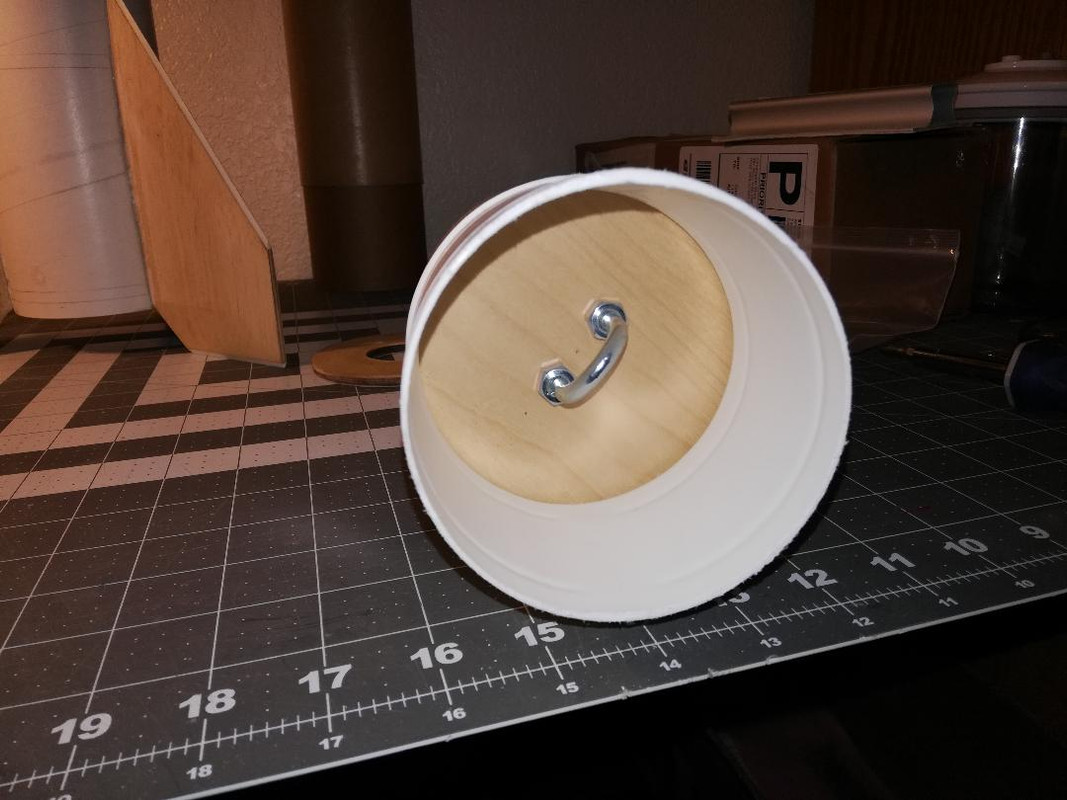

Might it be good to install a small stud, or two, in the nosecone bulkhead in anticipation of as a method of installing pre-drilled, measured lead weights to accomplish the optimum CG depending on the configuration? Or could that additional weight at such a relatively long arm/moment bite me on smaller, 29mm 'small field' motors?

How do you deal with the need for CG adjustment flexibility?

I am wondering how you approach building in the option to add/remove nose weight for rockets where your CG may vary due to using a wide variety of motors and/or motor tube adapters or standard vs. dual deployment/e-bay recovery modes?

I have done the ubiquitous nosecone mod but have not epoxied it into place yet. I have not finished the rocket, so I do not have a final weight to start plugging in numbers. An additional complicating factor is that - providing the weight works out to 1500g. or under - I would like to be able to fly it at the local field on smaller 29mm reloads, but would like to build an HP option with an electronics bay coupler and extended BT to obtain my L1 and use HP 38mm loads.

It may well be that with the coupler and larger motors I might not even need the option for nose weight adjustment, but I would like to have the option if needed.

Might it be good to install a small stud, or two, in the nosecone bulkhead in anticipation of as a method of installing pre-drilled, measured lead weights to accomplish the optimum CG depending on the configuration? Or could that additional weight at such a relatively long arm/moment bite me on smaller, 29mm 'small field' motors?

How do you deal with the need for CG adjustment flexibility?