shanejohnson2002

BT60 Enthusiast

- Joined

- Feb 6, 2019

- Messages

- 193

- Reaction score

- 155

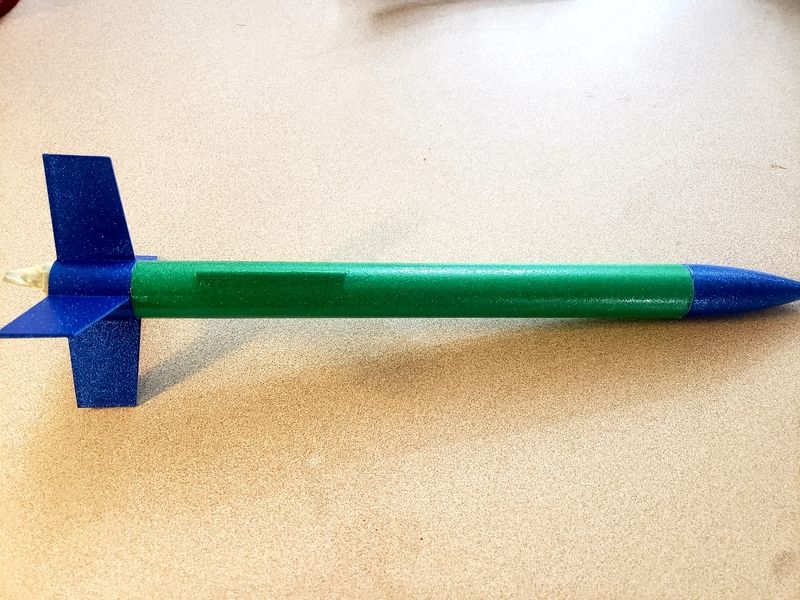

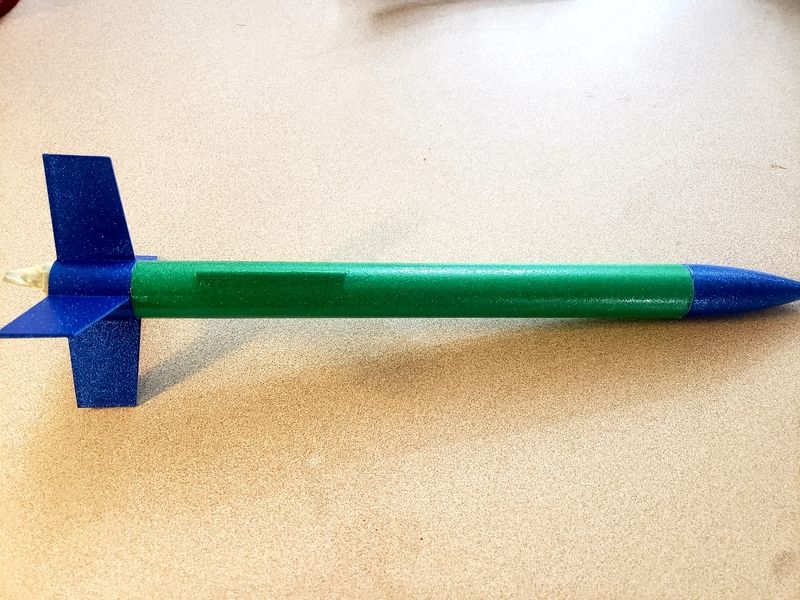

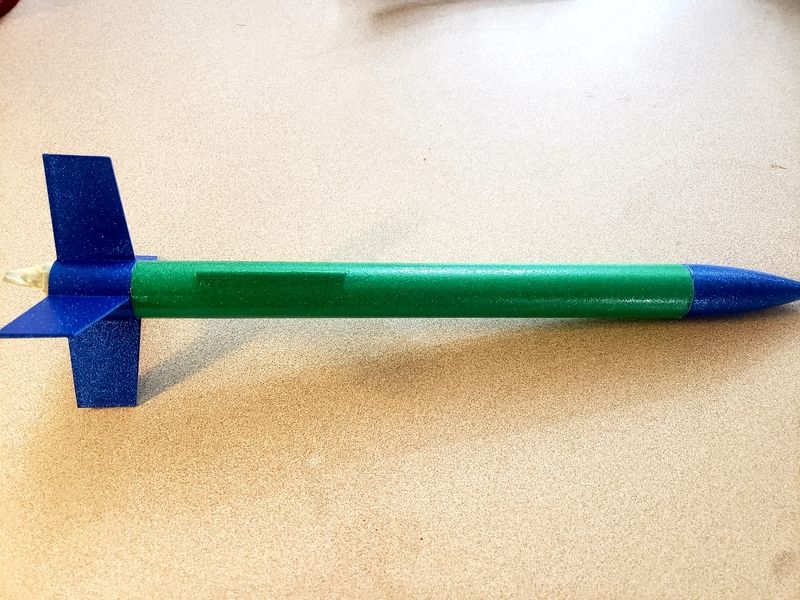

Got this one ready for decals:

Centering ring work on the Polecat BBII. Very clever setup.

I love it when a plan comes together...View attachment 374620

CI(VII): [Is that "101(7)"? April 11, 2007?]I'll still vote for marketing that: Tracker Carousel, fits x/y/z tracker! (must use ab123 Lipo)

CI(VII): [Is that "101(7)"? April 11, 2007?]

With the CAD software you're using, how hard would it be to divide this into four pieces? One is the core with battery slots, and it's OK if the slots only fit a narrow range of battery choices. Then a piece for each electronics face. The printable piece is made by slapping together the core and up to three faces, with the core-to-face interface standardized.

If all that can be done without too much difficulty, then you could have a library faces for lots of different electronics modules and print off custom combinations to order.

Thats one step closer Ryan!Jammed seven centering rings and a tail cone into a body tube.View attachment 374763 View attachment 374764

Honestly, I had the exact same idea. I was just being lazy, so never got around to posting suggestion...CI(VII): [Is that "101(7)"? April 11, 2007?]

With the CAD software you're using, how hard would it be to divide this into four pieces? One is the core with battery slots, and it's OK if the slots only fit a narrow range of battery choices. Then a piece for each electronics face. The printable piece is made by slapping together the core and up to three faces, with the core-to-face interface standardized.

If all that can be done without too much difficulty, then you could have a library faces for lots of different electronics modules and print off custom combinations to order.

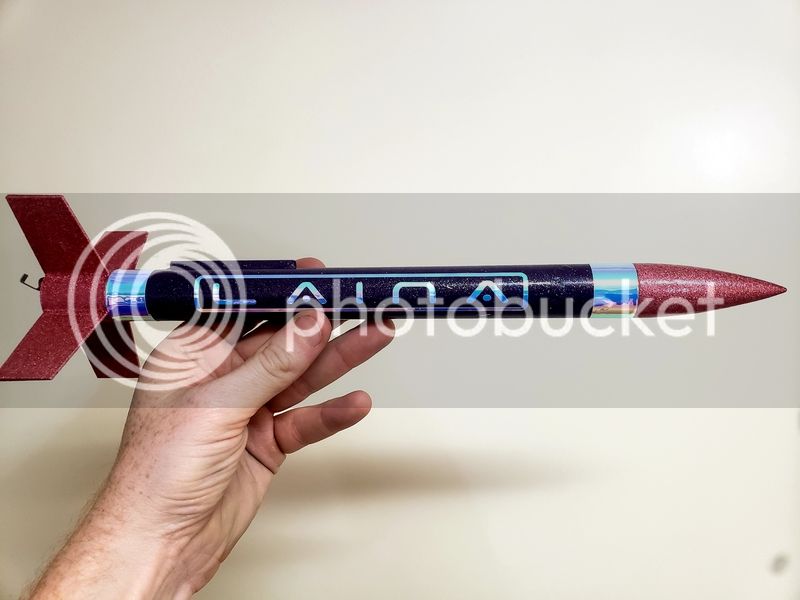

Any video links?Got a picture of the GBI mk24 from TurbulentSphere

The 24mm version was a little squirrelly on the way up and around burnout, but for what it's worth, I have seen some finned rockets fly worse.

The 24mm version was a little squirrelly on the way up and around burnout, but for what it's worth, I have seen some finned rockets fly worse.

Congrats! Any rocket retrieved in one piece is good news.Weather was iffy today, and on the cold side. As soon as it cleared up a bit we went and did some test launches at our local soccer field complex. 3 went up, 3 came down in one piece. All looked very straight/stable as they flew, so no complaints. Most importantly, the kids absolutely enjoyed it. They've been yammering about rockets since we left.

Had some pretty questionable parachutes though....stock plastic 12", and only one fully deployed. One streamered, and one didn't release the lines from the burrito fold. Looks like I need either new (probably thin mil nylon) chutes, or to apply more chalk.

Also think the A8-3s are on the bottom, most ragged edge of performance envelope. Perfect for the test flight today, and to stay under the low cloud cover. Probably need to step up to Bs of some sort.

“On the cold side” means plastic ‘chutes don’t want to open as you have seen. The best defense against that I know is talcum powder and packing them as close to launch time as you can get away with. There’s enough room in the Generic and the Crossfire to only have fold the spiked ‘chute in half at least.

We have a few “didn’t open” incidents at our club launch today (temps in the low 40s Fahrenheit) but the ground was quite soft from recent rains and snows so I don’t think there was any undue damage.

Also, lesson learned: put the chalk/talc/whatever in a small gladware container, and use a spoon or measuring cup. Pouring it straight from the container in the field isn't the easiest.

Foamed the nose cone on the Nuclear Sledgehammer.

View attachment 374894

Sounds kind of tasty, but no, thats the green painters tape to keep the nasty two part polyurethane foam from getting everywhere, the stuff is amazingly sticky. For those interested the foam is actually Sika Post Fix from Lowes a two part foam for filling around fence posts and appears and acts like the 2 part foam commonly used in rocketry applications. Its cheap, is about 2-3lbs/cu ft density and about 20:1 expansion ratio. I recently did a thread about it in Techniques iirc. It added about 14oz's to the 7.5" GLR nosecone (same as Loc afaik) The center tube is a 4" mailer tube (4" Loc airframe fits inside it).Are you sure you’re not making steamed pork buns inside some freaky green steamer?

Enter your email address to join: