You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TruCore casing spare parts

- Thread starter bdureau

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

5x7

Well-Known Member

- Joined

- Jan 19, 2009

- Messages

- 948

- Reaction score

- 118

I think for the 24s this was the tubing, turned down to 24mm:

https://www.onlinemetals.com/merchant.cfm?pid=13227&step=4&showunits=inches&id=71&top_cat=0

https://www.onlinemetals.com/merchant.cfm?pid=13227&step=4&showunits=inches&id=71&top_cat=0

patelldp

Well-Known Member

- Joined

- Jan 23, 2009

- Messages

- 5,647

- Reaction score

- 101

Kosdon ran 1" OD x 0.065" thickness cases: https://www.onlinemetals.com/myaccount/index.cfm?fuseaction=orderdetail&orderid=1153175

That allows you to use the same liner as Aerotech 24mm: https://www.rocketmotorparts.com/Paper_Motor_Liner,_24mm/p1577809_7795898.aspx

That said, Frank left them 1.0" OD which required the use of an adapter to 29mm. I love my little 1.0-40 E40F motor, I think I still have 7-8 Frank reloads for it and I have a ton of materials from RCS to make more reloads...someday!

That allows you to use the same liner as Aerotech 24mm: https://www.rocketmotorparts.com/Paper_Motor_Liner,_24mm/p1577809_7795898.aspx

That said, Frank left them 1.0" OD which required the use of an adapter to 29mm. I love my little 1.0-40 E40F motor, I think I still have 7-8 Frank reloads for it and I have a ton of materials from RCS to make more reloads...someday!

5x7

Well-Known Member

- Joined

- Jan 19, 2009

- Messages

- 948

- Reaction score

- 118

Who did you get those from?

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

I tested a 38mm 4 grains motor and it worked quite well

Here is the video

and this is the nozzle after firing

I now have spare parts for my Trucore motors that are no longer available and I would like to thanks all the members of the forum who helped me retrieving the nozzle and casing measurements.

Here is the video

and this is the nozzle after firing

I now have spare parts for my Trucore motors that are no longer available and I would like to thanks all the members of the forum who helped me retrieving the nozzle and casing measurements.

- Joined

- Jan 30, 2016

- Messages

- 8,993

- Reaction score

- 3,518

I would stick with 6061 unless you have some reason for 7075.

I am now getting the casings and forward plugs done. I am going to get them anodized as well.

Which aviation grade aluminum would you recommend? 7075? 2017A? or any other one?

NFPA 1125 requires commercial motor casings to be made of 6061-T6. Those requirements only apply to commercial motors, but I know of no reason not to emulate what commercial mfrs. do.

- Joined

- Jan 30, 2016

- Messages

- 8,993

- Reaction score

- 3,518

6061-T6 is what AT, CTI, and Loki all make their cases out of.

It's not as strong as 7075 at room temperature, but at acceptable firing temps a lot of that difference disappears.

7075 is also more expensive, more difficult to machine, and corrodes more easily.

It's not as strong as 7075 at room temperature, but at acceptable firing temps a lot of that difference disappears.

7075 is also more expensive, more difficult to machine, and corrodes more easily.

I thought that 6061 was food grade aluminum? Is it strong enough?

It has been strong enough for many years. [emoji3]

Keep in mind that more strength isn’t always a good thing. If there’s a crack in a fuel grain that causes a cato you want the failure to happen at a lower pressure rather than a higher pressure. The failure will happen no matter what, but failing at a lower pressure results in the parts flying less distance.

- Joined

- Nov 21, 2011

- Messages

- 482

- Reaction score

- 217

7075 tends to be frangible (lots of pieces if it bursts) while 6061 cases tend to stay in 1-2 pieces.

7075 is also more difficult to anodize than 6061, and is extremely prone to corrosion.

6061 is also a lot less expensive than 7075.

I will only use 7075 for small, single use, thin wall cases where I need every ounce of performance out of a completely custom motor/airframe.

7075 is also more difficult to anodize than 6061, and is extremely prone to corrosion.

6061 is also a lot less expensive than 7075.

I will only use 7075 for small, single use, thin wall cases where I need every ounce of performance out of a completely custom motor/airframe.

rharshberger

Well-Known Member

This is why we use 6061-T6, casing is only split, no fragments.7075 tends to be frangible (lots of pieces if it bursts) while 6061 cases tend to stay in 1-2 pieces.

7075 is also more difficult to anodize than 6061, and is extremely prone to corrosion.

6061 is also a lot less expensive than 7075.

I will only use 7075 for small, single use, thin wall cases where I need every ounce of performance out of a completely custom motor/airframe.

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

Holy Mackeral. Those are Beautiful.

- Joined

- Jan 30, 2016

- Messages

- 8,993

- Reaction score

- 3,518

+1, looks great! Any chance of the 24mm .scads on GH?

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

I have started drawing them but I have not published them yet. I will do on my github.+1, looks great! Any chance of the 24mm .scads on GH?

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

Well they are but the anodization will not last long on the insideHoly Mackeral. Those are Beautiful.

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

Hello everyone

It has been 3 years since I started making spare parts for TruCore casing and after spending quite a lot of money I finally got where I wanted with the help from a friend in my rocketry club who is a machinist in his spare time.

The first parts that I got made such as nozzle and forward plugs were machined in China. The anodization on the plug does not last long so I have decided not to do that on the latest casings. Selecting the right graphite with high density as also been a been very challenging. We have also been able to find the correct aluminium tubes so that we do not have to drill them.... This is very expensive when you have to drill them

So my friend has been able to machine 29mm, 38mm and 54 mm casing.

In the last 6 months; we have tested extensively the 38mm from 1 grain to 6 grains and the results are very good. The casing tube is anodized in black or colorless, the plug are not anodized and the nozzle are polished.

We even made 600 meters of casting tubes and liners which should last few years for our own use between us to.

The reason we did it is because we had a shortage of commercial motors in Europe in the last 3 years so we had to come up with solutions to continue launching rockets!!!!

They are slightly different from the original TruCore but still compatible

This is what they look like from 1 to 6 grains

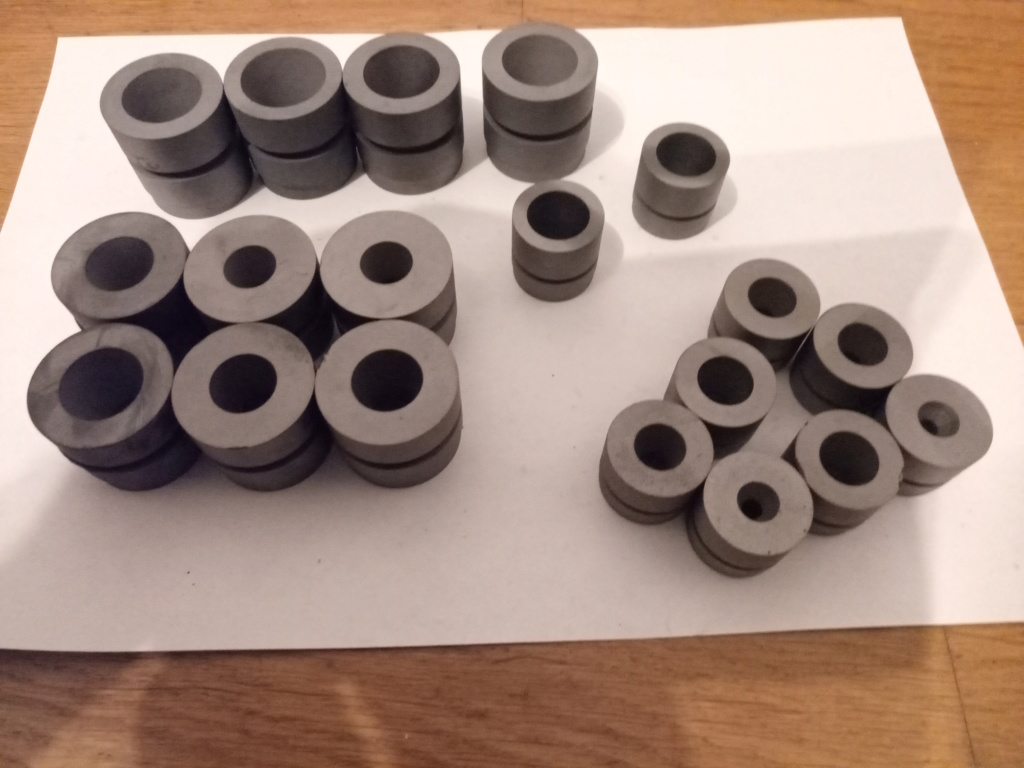

The nozzle. We are also optimizing them for sugar propellant

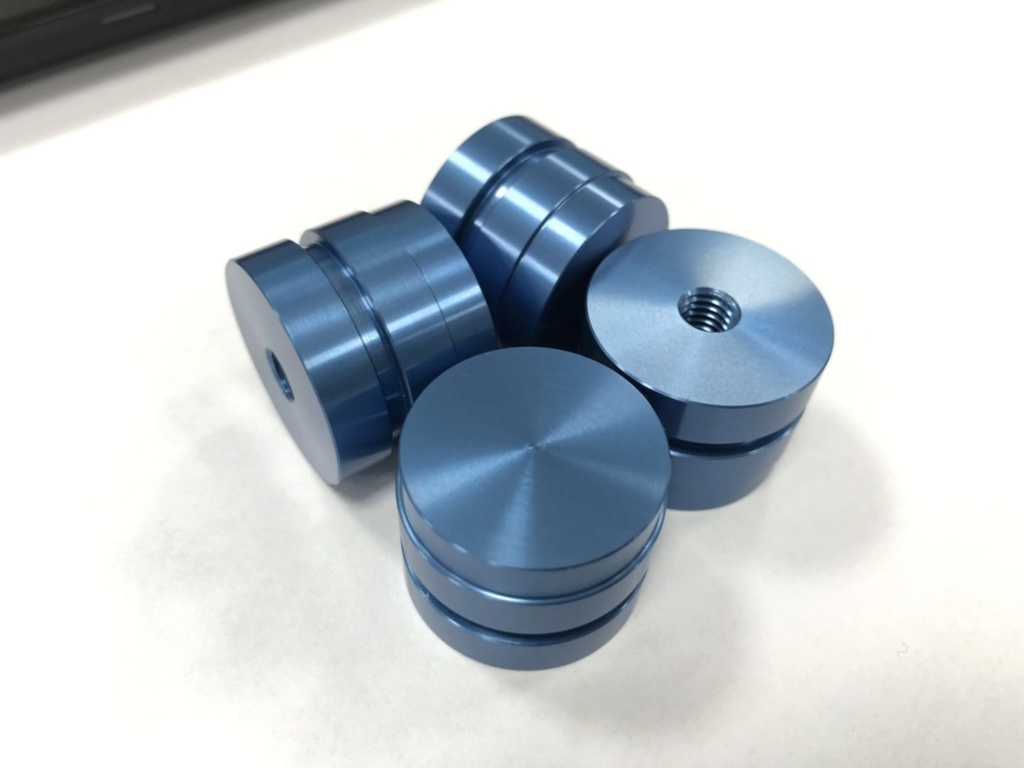

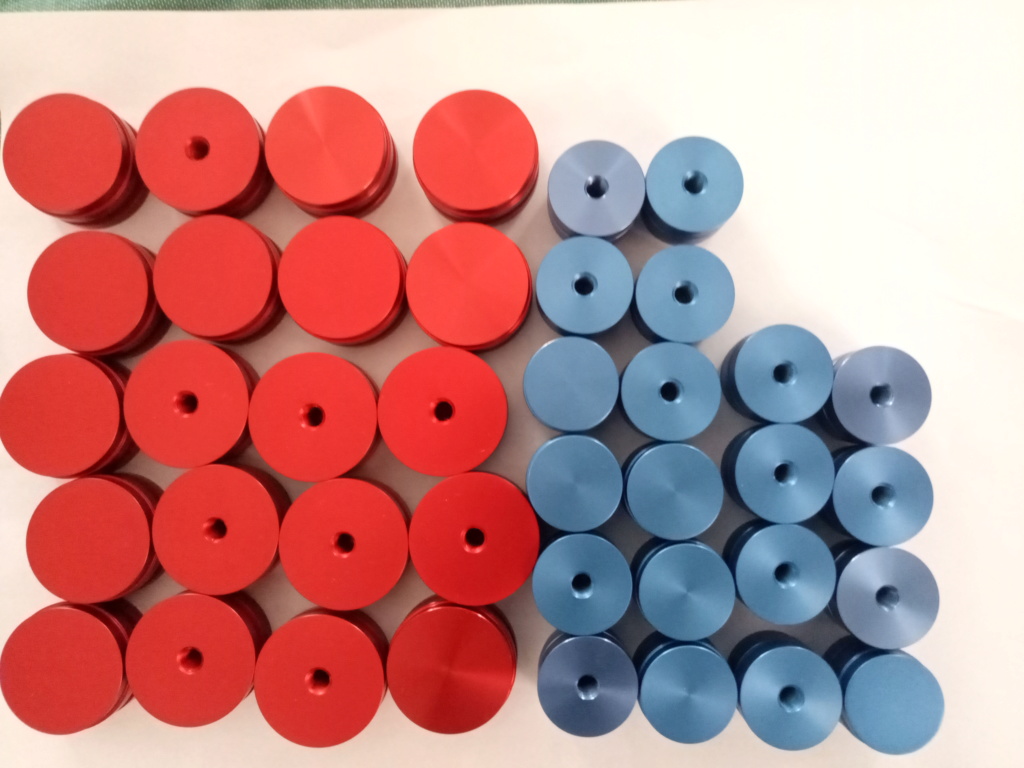

The plugs. Because we are in Europe and we use metrics you can screw a 6mm screw

And the casting tubes (we have few boxes of those plus some liners)

The retainer for the motor is just an external circlip

This is a picture of one of the flight my friend did with a 54 mm 2 grains sugar/titanium based propellant

Overall it was a very interesting experience for the 2 of us dealing with various suppliers but it is not cheap !!! between the two of us we spent few thousands dollars and ended up buying all the tools to make them!!!!

Now if anybody is interested to byy some custom parts I cannot do them myself but PM me and I give you my friend details and he might be able to do some for you.

It has been 3 years since I started making spare parts for TruCore casing and after spending quite a lot of money I finally got where I wanted with the help from a friend in my rocketry club who is a machinist in his spare time.

The first parts that I got made such as nozzle and forward plugs were machined in China. The anodization on the plug does not last long so I have decided not to do that on the latest casings. Selecting the right graphite with high density as also been a been very challenging. We have also been able to find the correct aluminium tubes so that we do not have to drill them.... This is very expensive when you have to drill them

So my friend has been able to machine 29mm, 38mm and 54 mm casing.

In the last 6 months; we have tested extensively the 38mm from 1 grain to 6 grains and the results are very good. The casing tube is anodized in black or colorless, the plug are not anodized and the nozzle are polished.

We even made 600 meters of casting tubes and liners which should last few years for our own use between us to.

The reason we did it is because we had a shortage of commercial motors in Europe in the last 3 years so we had to come up with solutions to continue launching rockets!!!!

They are slightly different from the original TruCore but still compatible

This is what they look like from 1 to 6 grains

The nozzle. We are also optimizing them for sugar propellant

The plugs. Because we are in Europe and we use metrics you can screw a 6mm screw

And the casting tubes (we have few boxes of those plus some liners)

The retainer for the motor is just an external circlip

This is a picture of one of the flight my friend did with a 54 mm 2 grains sugar/titanium based propellant

Overall it was a very interesting experience for the 2 of us dealing with various suppliers but it is not cheap !!! between the two of us we spent few thousands dollars and ended up buying all the tools to make them!!!!

Now if anybody is interested to byy some custom parts I cannot do them myself but PM me and I give you my friend details and he might be able to do some for you.

jimzcatz

Boss, Carolina Rocket Mafia

When you say plugs do you mean forward bulkheads? If you plan to release for public sale I would drop the anodizing and polishing and pass the savings on to the customer. Non of Ed's stuff was anodized. Good luck with your future endeavors.

bdureau

Well-Known Member

- Joined

- Dec 20, 2011

- Messages

- 539

- Reaction score

- 246

We do not anodized the forward bulkheads anymore because it does not last, however the tubes are anodized either in black or colorless.

I have done many test, go stuff made in China and then my friend started making them. So far we have done them just for ourselves . I personally need to do lots of launches to test all my electronic hardware and with Ed stopping making them and commercial motor shortage in Europe I had to find solutions to continue.

I have done many test, go stuff made in China and then my friend started making them. So far we have done them just for ourselves . I personally need to do lots of launches to test all my electronic hardware and with Ed stopping making them and commercial motor shortage in Europe I had to find solutions to continue.

Very nice. The loss of Tru-Core has been devastating for research rocketry.

Similar threads

- Replies

- 14

- Views

- 775

- Replies

- 26

- Views

- 2K

- Replies

- 11

- Views

- 355