Or PETG.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing 3D Printed Rail Buttons and Guides

- Thread starter Jack Hydrazine

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AlphaHybrids

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,573

- Reaction score

- 97

I wonder how ABS takes the friction? I have delrin buttons with 20 flight on them and only a bit of a flat spot. And they only cost me a quarter each. For standard buttons, I wonder if 3D printing is the best process. Especially since there will almost always be a bond layer where it transitions back to the outer part of the button that holds the rocket on. Maybe some pull out tests would see where that shears off at.

Edward

Edward

I see what you mean. I'll try to come up with something. Still adds more drag than necessary.

It might smooth air flow over the screw head on the non-recessed version.

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

I wonder how ABS takes the friction? I have delrin buttons with 20 flight on them and only a bit of a flat spot. And they only cost me a quarter each. For standard buttons, I wonder if 3D printing is the best process. Especially since there will almost always be a bond layer where it transitions back to the outer part of the button that holds the rocket on. Maybe some pull out tests would see where that shears off at.

Edward

Considering how cheap it is to print them I am of the opinion that it is the best process.

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

Or PETG.

PETG is a decent material for this application.

But it does often need sanded before use.

Last edited:

SteveThatcher

SMT Designs

I wonder how ABS takes the friction? I have delrin buttons with 20 flight on them and only a bit of a flat spot. And they only cost me a quarter each. For standard buttons, I wonder if 3D printing is the best process. Especially since there will almost always be a bond layer where it transitions back to the outer part of the button that holds the rocket on. Maybe some pull out tests would see where that shears off at.

Edward

Jack's designs all have a machine screw "post" that will add a substantial amount of strength to the guide. The 3d printer will basically make a solid cylinder with the machine screw outside diameter and the rail "width" minus a bit for clearance. The optimum screw size for the 1010 rails will be 6-32 and I always have an internal backing plate that is threaded to keep the screw in place anyway (also lets me replace the guides easily and take them off for painting). When you print the part, you can always vary the "fill" percentage and even make it 100% if you wanted to. I have tested my shock cord tie plates to 160 pounds static strength (without breaking) and I print them in PETG at 50% fill.

I did find a interesting reference on gizmodorks.com and they said PETG had better abrasion resistance than delrin and nylon - not sure I believe that, but wanted to at least mention it for something to look up. https://gizmodorks.com/blog/3d-printer-filament-types/

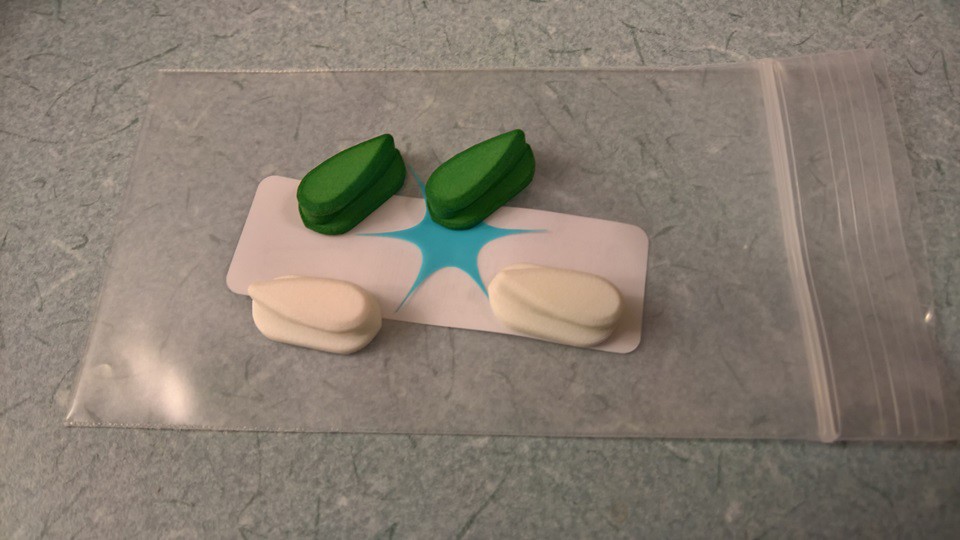

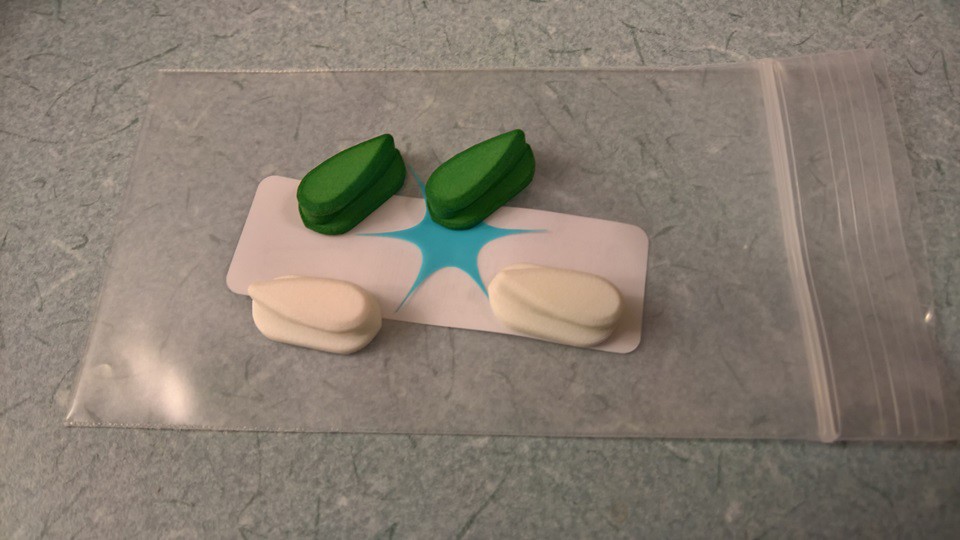

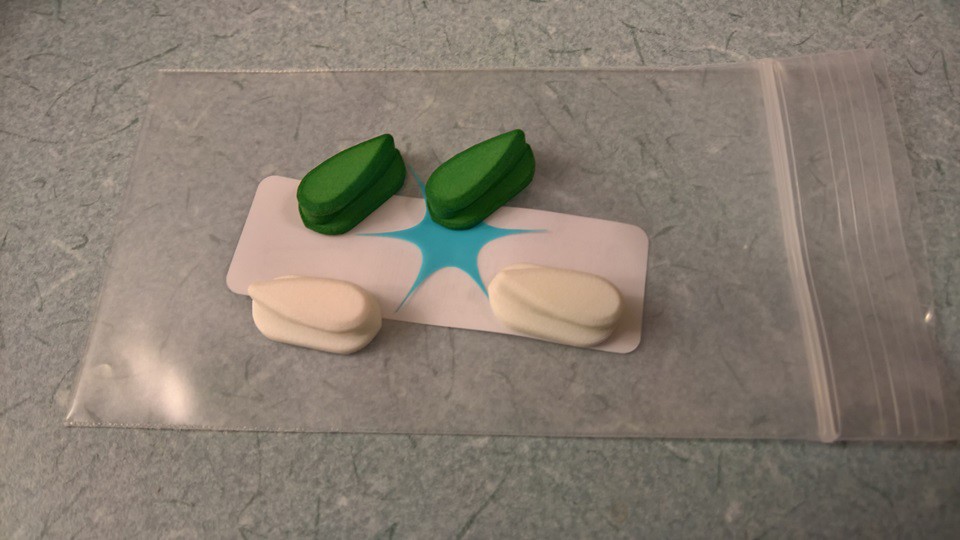

I printed some in clear PETG. Need a little sanding but they are very tough.

SteveThatcher

SMT Designs

I printed some in clear PETG. Need a little sanding but they are very tough.

PETG is a nice material. I hardly ever sand the PETG parts I make though. I use an exacto knife to trim. It you are getting little zits and things (beyond hairs and threads of PETG), then there could be some printing adjustments that would help.

Last edited:

Thanks

SteveThatcher

SMT Designs

Thanks

you are very welcome.

This probably only applies to the low cost hobby printers (I would expect commercial printers to not have this issue), but another reason you can get blobs/zits is what you are using to print from. If you are printing directly from an attached SD card, you shouldn't have any issue. If you are printing from Wifi, network, or USB, you can get blobs whenever the printer is extruding filament and the printer firmware is waiting for the next G code to come in. As long as the "source" is responsive, you won't have an issue, but if you are running other applications, downloading updates, or whatever - that source can affect the responsiveness of the codes flowing to the printer. Whenever the printer is waiting, filament can be leaking a bit at that point.

I recently helped a guy on Facebook with the exact same issue. He could not understand why one day, all his prints starting having little zits on the walls. He said he was printing from a SD card, then he said he was using Octoprint. It turned out the the Arduino platform that he was running Octoprint on (that had the SD card) needed to be rebooted. It had added some task that was affecting the codes flowing to his printer.

So if you see a change in behavior with print quality, it isn't always the printer itself. I had to reboot my PC I run MatterControl on one day for the same reason also.

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

The next set of 1010 aero rail buttons are those with the integrated standoff.

1/2 inch standoff

https://www.thingiverse.com/thing:3092649

3/8 inch standoff

https://www.thingiverse.com/thing:3056148

1/4 inch standoff

https://www.thingiverse.com/thing:3079281

3/16 inch standoff

https://www.thingiverse.com/thing:3092654

1/2 inch standoff

https://www.thingiverse.com/thing:3092649

3/8 inch standoff

https://www.thingiverse.com/thing:3056148

1/4 inch standoff

https://www.thingiverse.com/thing:3079281

3/16 inch standoff

https://www.thingiverse.com/thing:3092654

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

The next set of 1010 aero rail buttons are those with the integrated standoff.

1/2 inch standoff

https://www.thingiverse.com/thing:3092649

3/8 inch standoff

https://www.thingiverse.com/thing:3056148

1/4 inch standoff

https://www.thingiverse.com/thing:3079281

3/16 inch standoff

https://www.thingiverse.com/thing:3092654

1/2 inch standoff

https://www.thingiverse.com/thing:3092649

3/8 inch standoff

https://www.thingiverse.com/thing:3056148

1/4 inch standoff

https://www.thingiverse.com/thing:3079281

3/16 inch standoff

https://www.thingiverse.com/thing:3092654

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

I'm now on to creating conformal versions of what I have designed up to now.

1010 Conformal Aero Rail Button 3/16" (4.76mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3115148

1010 Conformal Aero Rail Button 3/16" (4.76mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3115148

Last edited:

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

I'm now on to creating conformal versions of what I have designed up to now.

1010 Conformal Aero Rail Button 3/16" (4.76mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3115148

1010 Conformal Aero Rail Button 3/16" (4.76mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3115148

Last edited:

EXPjawa

Well-Known Member

I've been using these 3D printed conformal airfoil buttons that I've had Shapeways.com print:

They get epoxied to the surface. Shapeways uses nylon as a default material, and that seems to be working pretty well for this type of part. I will caution that they need to be printed at high resolution to have decent structure; the section thickness are small enough that there isn't a lot of forgiveness for gaps in the layers.

They get epoxied to the surface. Shapeways uses nylon as a default material, and that seems to be working pretty well for this type of part. I will caution that they need to be printed at high resolution to have decent structure; the section thickness are small enough that there isn't a lot of forgiveness for gaps in the layers.

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Aero Rail Button 1/4" (6.35mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3125414

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3125414

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

I'm now on to creating conformal versions of what I have designed up to now.

1010 Conformal Aero Rail Button 3/16" (4.76mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3115148

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

I've been using these 3D printed conformal airfoil buttons that I've had Shapeways.com print:

They get epoxied to the surface. Shapeways uses nylon as a default material, and that seems to be working pretty well for this type of part. I will caution that they need to be printed at high resolution to have decent structure; the section thickness are small enough that there isn't a lot of forgiveness for gaps in the layers.

Very nice!!!

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

Here is another conformal rail button standoff I have created and posted to Thingiverse.com that you can download for free and print.

1010 Conformal Aero Rail Button 1/4" (6.35mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3125414

1010 Conformal Aero Rail Button 1/4" (6.35mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3125414

Last edited:

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Aero Rail Button 3/8" (9.53mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3150150

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3150150

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Aero Rail Button 3/8" (9.53mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3150150

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3150150

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Aero Rail Button 1/2" (12.7mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3153215

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3153215

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Aero Rail Button 1/2" (12.7mm) Standoff

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3153215

They are designed to be conformal to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.). They are compatible with the 1010 aero rail buttons I have designed above.

https://www.thingiverse.com/thing:3153215

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Standard Rail Button

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail. By being conformal they are designed to be more aerodynamic by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3168920

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail. By being conformal they are designed to be more aerodynamic by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3168920

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Standard Rail Button

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail. By being conformal they are designed to be more aerodynamic by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3168920

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail. By being conformal they are designed to be more aerodynamic by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3168920

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Standard Rail Button Rounded

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail that is rounded and is conformal. By being conformal and rounded they are designed to be even more aerodynamic than the standard conformal button and by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3178417

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail that is rounded and is conformal. By being conformal and rounded they are designed to be even more aerodynamic than the standard conformal button and by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3178417

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

1010 Conformal Standard Rail Button Rounded

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail that is rounded and is conformal. By being conformal and rounded they are designed to be even more aerodynamic than the standard conformal button and by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3178417

This is a standard rail button designed for the 1010 size 8020 aluminum extrusion rail that is rounded and is conformal. By being conformal and rounded they are designed to be even more aerodynamic than the standard conformal button and by conforming to the rocket airframe tubes in these standard sizes - 38mm (1.5 in.), 54mm (2.13 in.), 65mm (2.54 in.), 75mm (3 in.), 98mm (4 in.), 140mm (5.5 in.), 155mm (6 in.), and 195mm (7.5 in.).

You can download two versions of each airframe diameter - with and without a recess.

https://www.thingiverse.com/thing:3178417

Nytrunner

Pop lugs, not drugs

Great collection of parts!

Have you flight/load tested the rounded buttons? Some rocketeers hang their rockets underneath when raising the rails.

Have you flight/load tested the rounded buttons? Some rocketeers hang their rockets underneath when raising the rails.

- Joined

- May 31, 2011

- Messages

- 333

- Reaction score

- 132

Great collection of parts!

Have you flight/load tested the rounded buttons? Some rocketeers hang their rockets underneath when raising the rails.

Haven't tested any of them yet, but there are some rocketeers who are. I'll let you know what I find out. I would suggest printing them with ABS.

Similar threads

- Replies

- 1

- Views

- 360

- Replies

- 6

- Views

- 501

- Replies

- 9

- Views

- 748

- Replies

- 5

- Views

- 923

- Replies

- 19

- Views

- 2K