Nathan

☢

- Joined

- Apr 19, 2012

- Messages

- 2,230

- Reaction score

- 755

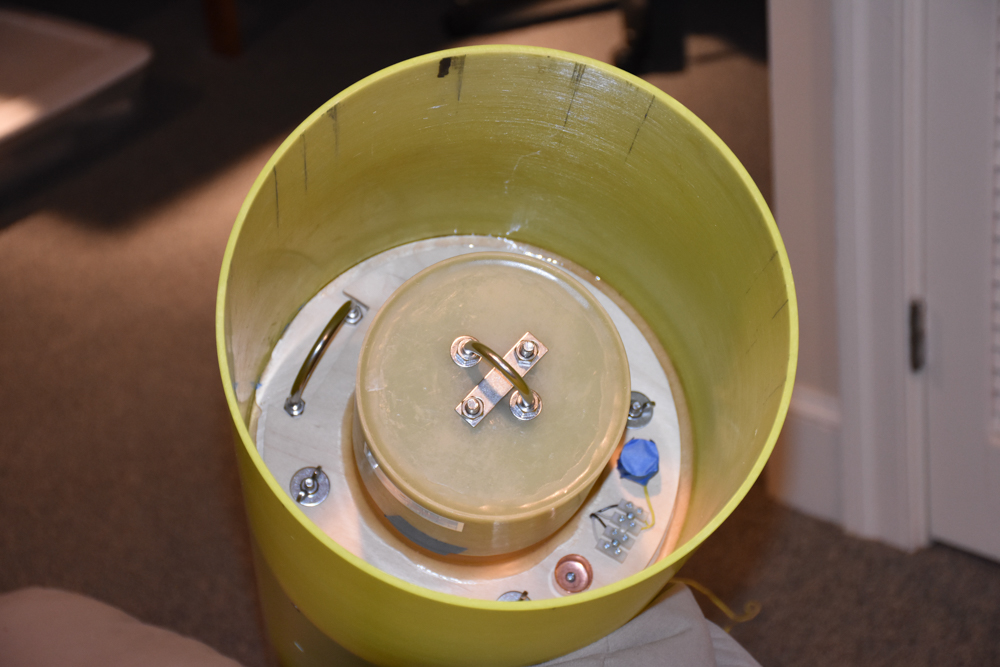

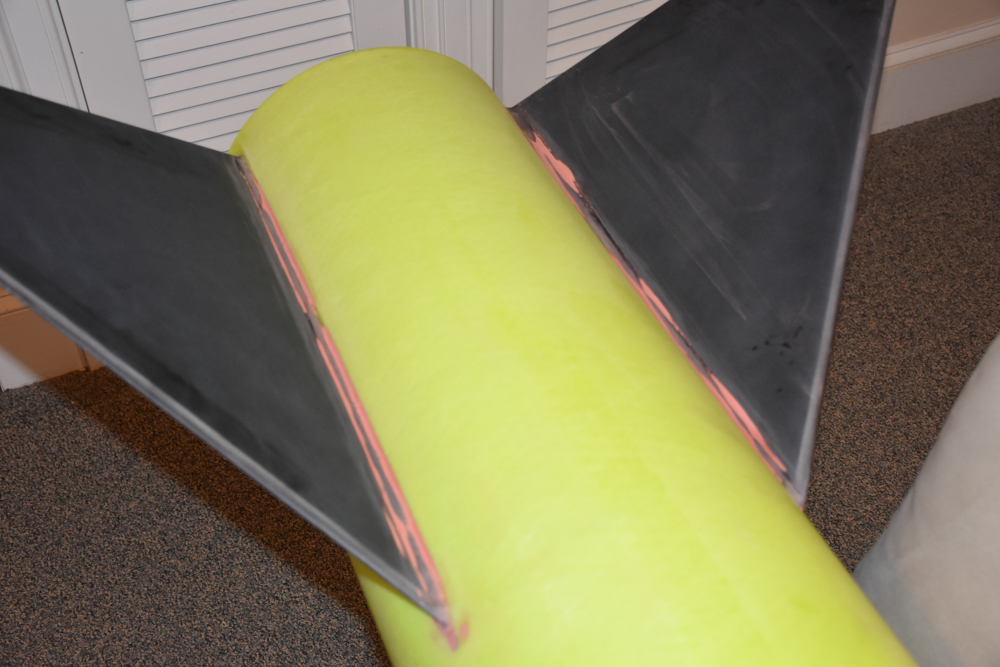

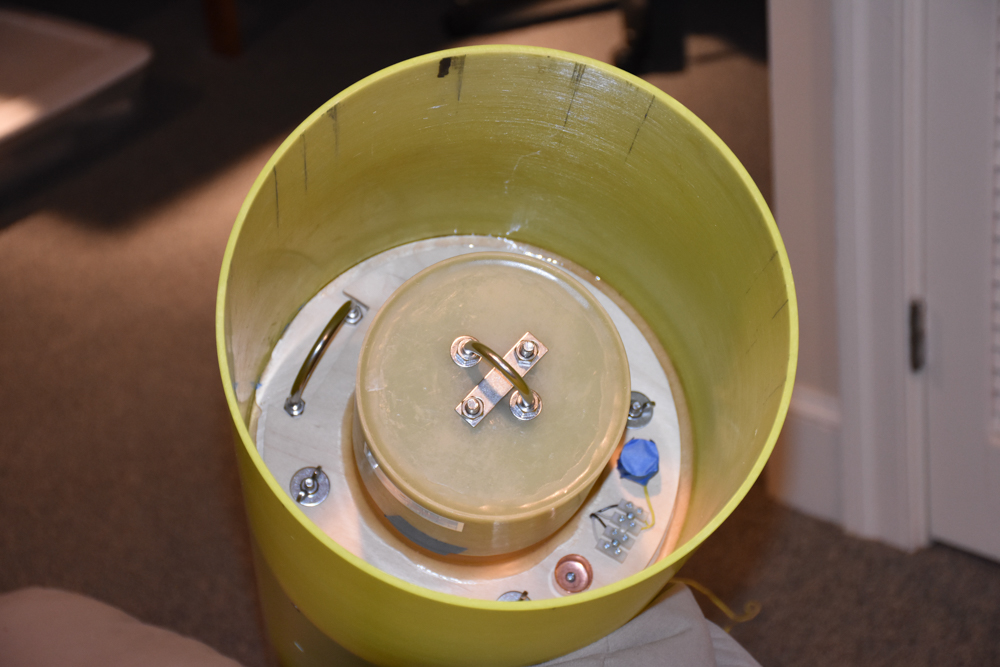

Cannon mounting ring installed in the airframe with epoxy and six countersunk #10 x 2" stainless screws.

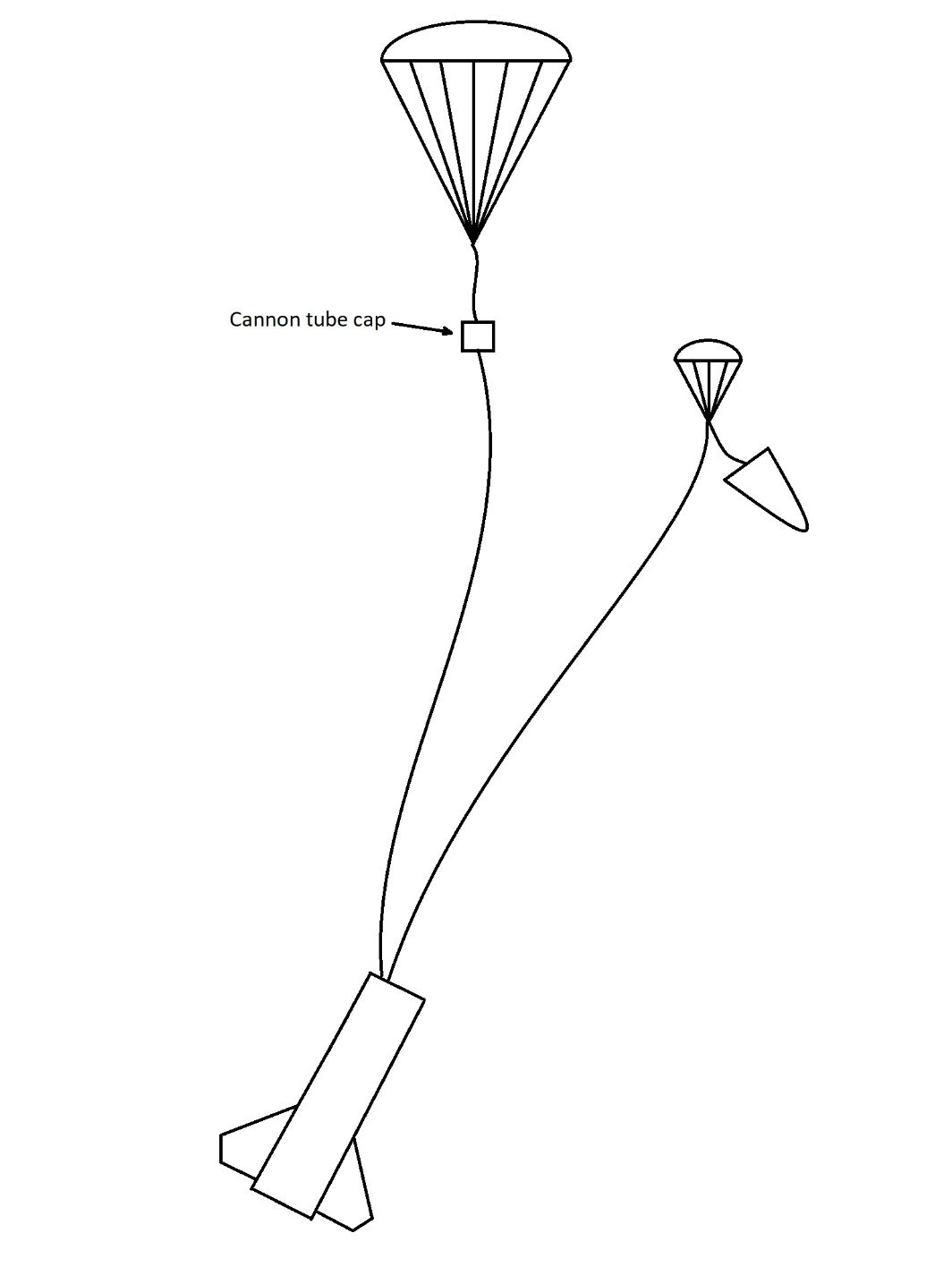

And here it is with a 3 gram charge loaded for an apogee deployment test tomorrow. I don't know if that will be the correct amount of powder. Just a guess, we'll see how it goes. Since I'm not testing the main deployment yet there is nothing in the cannon tube and I don't have any shear pins in the cannon cap so it's just held in place with some tape for now. I'll try to video the deployment tests.

And here it is with a 3 gram charge loaded for an apogee deployment test tomorrow. I don't know if that will be the correct amount of powder. Just a guess, we'll see how it goes. Since I'm not testing the main deployment yet there is nothing in the cannon tube and I don't have any shear pins in the cannon cap so it's just held in place with some tape for now. I'll try to video the deployment tests.