- Joined

- Nov 17, 2009

- Messages

- 527

- Reaction score

- 222

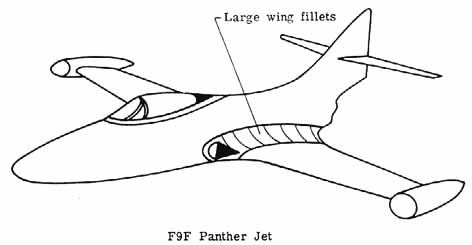

My exterior fin fillets need work.

Without getting into that technique, does anyone on the forum fillet their fins on the inside of the airframe only?

It seems to me that the exterior fin to airframe joint would be cleaner in appearance without a fillet.

Is there a structural disadvantage doing it this way?

I am referring to mid power rockets.

William

Without getting into that technique, does anyone on the forum fillet their fins on the inside of the airframe only?

It seems to me that the exterior fin to airframe joint would be cleaner in appearance without a fillet.

Is there a structural disadvantage doing it this way?

I am referring to mid power rockets.

William