GlenP

Well-Known Member

- Joined

- Oct 3, 2014

- Messages

- 3,065

- Reaction score

- 1,578

So, basically, the Angle of Attack, influenced by the Angle of Incidence of a Horizontal Stabilizer ( conventional "Stab" or a Canard ), determines what the Glider "sees", as being "upright".

What happens on a Delta planform, zero-dihedral, "flying wing" ( without any Horizontal Stabilizer) and symmetrical, vertical Rudder(s) that are above and below the Wing ? ( Think a fuselage-less Delta-Katt, without a Canard )

I am assuming that some type of "Elevator Flap" would be necessary . . .

Dave F.

View attachment 441797

View attachment 441798

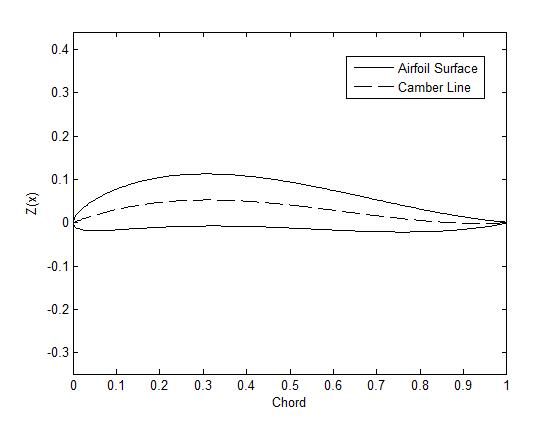

Yes, you need to balance the lift of the wing longitudinally with either a down force on an aft tail or an up force on a lifting canard to keep the nose pitched up in an attitude where the wing generates lift. Flying wings with no moveable control surfaces would require a special non-symmetric airfoil to trim for flight, ie trailing edge reflex is required to cancel out the pitching moment.

The fuselage stick on that particular delta-katt, according to the plans, has the incidence of the canard relative to the wing fixed to ensure you have a trimmed and balanced condition, they are not both at the same incidence angle. If you toss is upside down it will loop nose down until it uprights itself or hits the ground.

https://plans.rocketshoppe.com/mpc/mpc3-0930/mpc3-0930.htm