Just finished a 155 hour print - over 5 lbs of PETG.

timelapse - 1 frame every 15 minutes of printing

timelapse - 1 frame every 15 minutes of printing

Just finished a 155 hour print - over 5 lbs of PETG.

timelapse - 1 frame every 15 minutes of printing

It's the bottom half of a 10" diameter V2 fincan. Total height will be 80"

Fully 3d printed. The high power ’filament fleet’ is actually getting pretty big. We need some nicer weather

View attachment 405034

I'd be interested in trying to fly with grid fins.I've always had success with them, but I've seen some conversations on the internet stating that grid fins don't work at model scales. Printing out some test pieces to see how they compare to other configurations.

View attachment 405029

Have this one, but it is on the bigger side: https://www.thingiverse.com/thing:3419162I'd be interested in trying to fly with grid fins.

Do you have a 3D model I might be able to print?

I've always had success with them, but I've seen some conversations on the internet stating that grid fins don't work at model scales. Printing out some test pieces to see how they compare to other configurations.

View attachment 405029

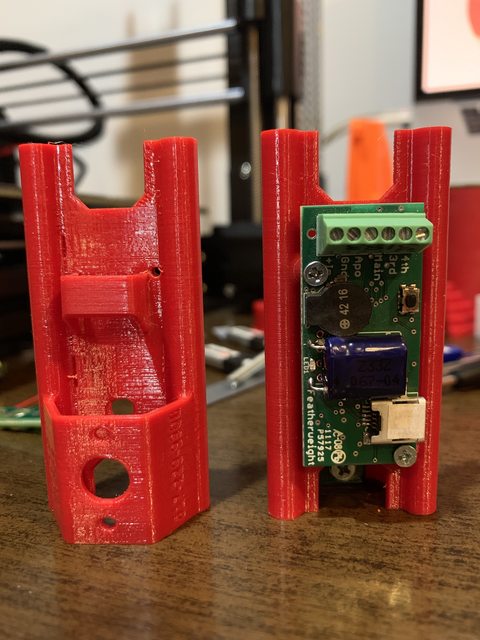

Working on sleds for TeleGPS, Raven 3, and Featherweight GPS this week, along with drill guides to install them. After about 10 prototype prints, I think these are basically done.

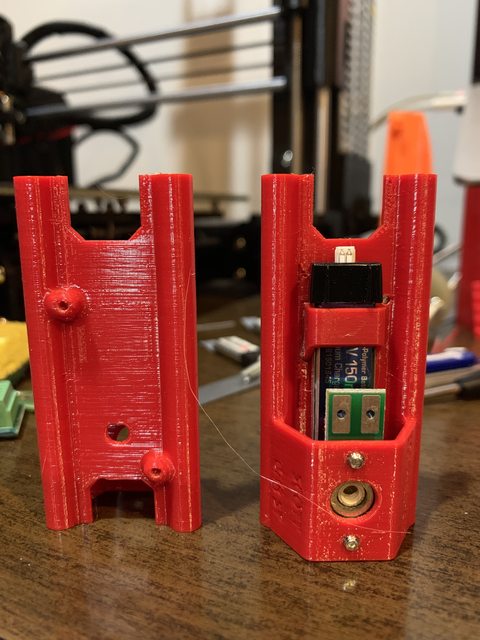

Finished up a sled design for 38mm minimum diameter rockets. It fits in a 3" long coupler and holds a Raven 3, 1s LiPo, and screw switch. My name and phone are embossed on the switch riser in the event someone else finds it before I do. The battery clip is printed separately then super glued on due to excessively stringy bridging when printed in situ. I'll work on bridging settings and integrate it later, but I declare this one done for now. I might take a soldering iron and do some plastic soldering to make sure the glue joint doesn't fail prematurely.

I printed a BB8 and maintenance cockpit for my HPR X Wing I am building.

I used 15 minute epoxy to put it together, is this going to be an issue with PLA?

If you are gluing PLA to PLA you should use 3DGloop. It welds the parts together, you will never get them apart. 15min epoxy does not stick well. Assuming you are using Bob Smith or equivalent, the 30 minute is better. BUT, Epoxy or CA does not stick that well to PLA, Forget about it with PETG. Epoxy will stick best to ABS or ASA made 3D parts. If you have to bond to 3D parts design them so there is a mechanical lock-fitment.

X Wing Droid Assembly on Flickr

X Wing Droid Added Captive Nuts on Flickr

X Wing Droid Assembly on Flickr

I've always had success with them, but I've seen some conversations on the internet stating that grid fins don't work at model scales. Printing out some test pieces to see how they compare to other configurations.

View attachment 405029

I've found PLA notoriously hard to glue to.

And, Epoxy & plastics rarely stick well, unless the plastic is nicely scuffed & scratched for the epoxy to 'bite into & hold onto'

expensive filament $52.00/kg

Fully 3d printed. The high power ’filament fleet’ is actually getting pretty big. We need some nicer weather

View attachment 405034

expensive filament $52.00/kg

So cheap. The ABS for the StrataSys we have is nearly $400/kg, if you buy the filament they intend to be used on it. We bypass the security system and use $25/kg filament.

View attachment 408119

View attachment 408119

Enter your email address to join: