Greetings!,

Even before I earned my NAR Level One in Hondo, TX with my 4" LOC Goblin I selected and purchased a Binder Fusion for my NAR Level Two. I've never done a complete build thread, so here is my attempt. Although I'm a fairly experienced aero-modeler, Rocketry is still something novel and I've much to learn. Feel free to let loose with feedback!

My first impression of the Fusion was - wow! This is how a kit is supposed to be delivered. May of the annoying things like guide rail lines and etc are already done for you. The materials are first rate, included are CP/CG decals as well as a complete decal wrap. This leaves only priming and the lower 25% or so to paint. Very nice. The instructions are very clear and there are details that I'll point out later that convince me that Scott certainly knows a thing or two about designing rockets and deploying them as kits. Again, very impressive.

The Fusions box it came in, packed very nicely - just like everything else - well done.

I hope to soon have this rocket complete displaying nicely next to my 4" LOC Goblin that I used to earn my NAR Level One.

Instructions, fin guides and CG/CP decals are first rate.

Ready to go!

Let's do this. . .

Glued the blind nuts, used oil in the threads to ensure glue wouldn't stick there. 30 minute epoxy on the eye nuts and bolts.

More of the same

Ditto.

More to come!

Mark!

Even before I earned my NAR Level One in Hondo, TX with my 4" LOC Goblin I selected and purchased a Binder Fusion for my NAR Level Two. I've never done a complete build thread, so here is my attempt. Although I'm a fairly experienced aero-modeler, Rocketry is still something novel and I've much to learn. Feel free to let loose with feedback!

My first impression of the Fusion was - wow! This is how a kit is supposed to be delivered. May of the annoying things like guide rail lines and etc are already done for you. The materials are first rate, included are CP/CG decals as well as a complete decal wrap. This leaves only priming and the lower 25% or so to paint. Very nice. The instructions are very clear and there are details that I'll point out later that convince me that Scott certainly knows a thing or two about designing rockets and deploying them as kits. Again, very impressive.

The Fusions box it came in, packed very nicely - just like everything else - well done.

IMG_2300

My current stable of rockets; low medium and high power. The LOC Goblin in the back is the...

IMG_2299

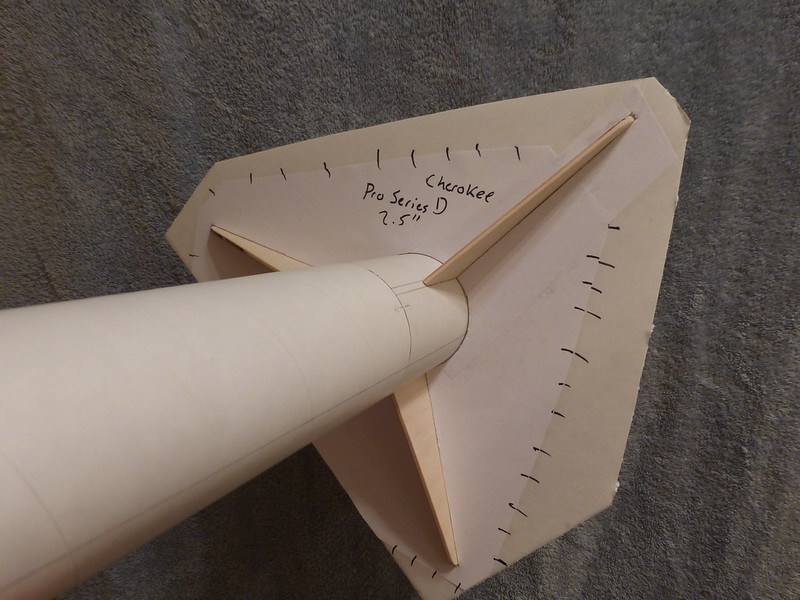

Glue the blind nuts. I oiled the threads first to ensure glue wouldn't stick.

More to come!

Mark!

Last edited: