Luke

Well-Known Member

- Joined

- Jun 13, 2013

- Messages

- 253

- Reaction score

- 7

Returning to the hobby after a few years and decided to delve straight in where I left off, getting into HPR. I have a 4" LOC V-2 which needs finishing, a scratch build planned for which I have the components and another scratch build which lawn darted and needs repairing, plus a Wildman Wildchild which is finished and I just need the courage to fly...

To keep things simple though, I decided to order a new kit and refresh the memory before messing around with projects I haven't touched in years. I like decent sized rockets and wanted something that would be easy to build an AV bay in and achieve a level 1 certification. I've never built anything with split fins and something about the Athena looked quite good to me, when I saw/heard it's ability to whistle I was sold and placed an order.

Plans for the build so far;

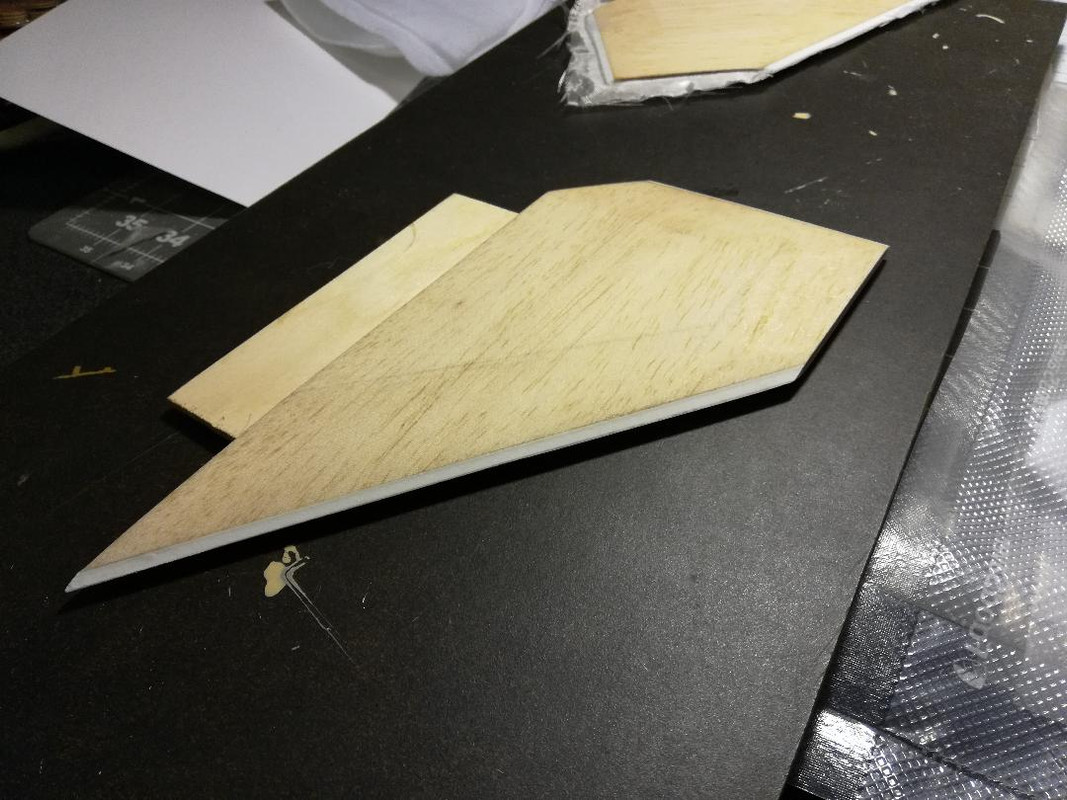

- Fibreglass the tubes and fins for durability and smooth finishing.

- Upgrade to a 38mm MMT (I thought I had a spare 29mm Aeropack retainer but I do not. I do however have a 38mm one, so it made sense to make the rocket more versatile with a 38mm mount than to spend more money on a new retainer).

- AV bay in upper payload. I intend to run dual deployment from a single break with a cable cutter around the main.

- Colour scheme is going to be hot pink with some black & white detailing.

Can't wait for it to turn up There's not much out there on the Athena from the searching I've done. Any photos or advice from those who've built it would be appreciated.

There's not much out there on the Athena from the searching I've done. Any photos or advice from those who've built it would be appreciated.

To keep things simple though, I decided to order a new kit and refresh the memory before messing around with projects I haven't touched in years. I like decent sized rockets and wanted something that would be easy to build an AV bay in and achieve a level 1 certification. I've never built anything with split fins and something about the Athena looked quite good to me, when I saw/heard it's ability to whistle I was sold and placed an order.

Plans for the build so far;

- Fibreglass the tubes and fins for durability and smooth finishing.

- Upgrade to a 38mm MMT (I thought I had a spare 29mm Aeropack retainer but I do not. I do however have a 38mm one, so it made sense to make the rocket more versatile with a 38mm mount than to spend more money on a new retainer).

- AV bay in upper payload. I intend to run dual deployment from a single break with a cable cutter around the main.

- Colour scheme is going to be hot pink with some black & white detailing.

Can't wait for it to turn up