jlabrasca

Well-Known Member

- Joined

- Oct 31, 2016

- Messages

- 1,429

- Reaction score

- 476

Looks like you got the Australian edition.

Maiden flight of my Estes v2 had one of those.. the rocket landed 1.5m from the pad.. I had the "nearest the pin" for a few launches till another member landed his OVER the launch rail (NC / chute on one side of the sawhorse, fin can over the other...)Had one of those only happens once in couple years....perfect flying day! NO WIND.

Flew my Punisher & top stage testing of Nike-Apache....flawless, perfect see all events flights!

And tomorrow should be the same.

Looks like you got the Australian edition.

I worked on this yesterday. I'm always tinkering with things in my rocket hobby. I jump from one thing to another. Some of my rockets only get started, then I'll set them aside, Others never get finished. Like this one, I've had sitting around for over a year. I want to try the chute release from jolly logic in it.

It's nothing special watheyak, Just that Estes BT-60 parabolic nose cone cut to fit a spiral ring retainer. I've been kind of upset lately. I made a kit up for Chuck (one of the mods.) So I go out to cut a 24 mm. retainer for it and my lath quite working. With pulling these sleeves you sure can get carried away with it. I've been looking at the loc. Nose cones and, I'm thinking it might be possible to do this with there nose cones and body tubes.Love the boat tail, too.

Neil beat you to it.

NARTS just stuffed the envelope upside down.

Did you epoxy fill between the forward and aft C/R's?Finished assembly on my 2” Frenzy. Just waiting on the weather to improve so I can do my ejection testing and start painting it. I was hoping to maiden it this coming weekend, but I’ll wait to properly test and paint it. Hopefully next month!

View attachment 363439

Did you epoxy fill between the forward and aft C/R's?

Tyler I was thinking the very same thing with one of these. I pulled one off my house and thought now that would make a good launch pad set up. Kool!I got started building my launch rail setup, which actually will work for my rod-launched rockets, also!

That is a really cool baffle design.

It's nothing special watheyak, Just that Estes BT-60 parabolic nose cone cut to fit a spiral ring retainer. I've been kind of upset lately. I made a kit up for Chuck (one of the mods.) So I go out to cut a 24 mm. retainer for it and my lath quite working. With pulling these sleeves you sure can get carried away with it. I've been looking at the loc. Nose cones and, I'm thinking it might be possible to do this with there nose cones and body tubes.

Ya, But you sure could have done a better job aligning those forward fins Nytrunner. Ha. I had to look twice. That's a good looking rocket.LOC cones do make good boattails! (Just.......make sure you prep the surface properly so the epoxy doesn't chip at the edges....)

Good luck!With signed test in hand, I'm ready to fly for L2 this Saturday at HARA's North Alabama Returns to Flight launch.

Sprung bayonet mounts, like a BNC connector?The plan is to have a completely tool-less way to assemble/disassemble AV Bay that includes: external switch connections, EggFinder mounting, NC attachment, etc... And all without using external rivets, screws or any other form of fastener.

Sprung bayonet mounts, like a BNC connector?

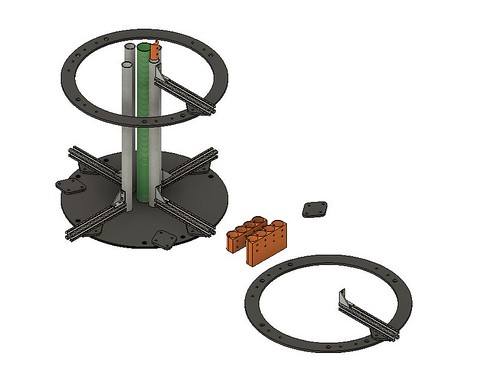

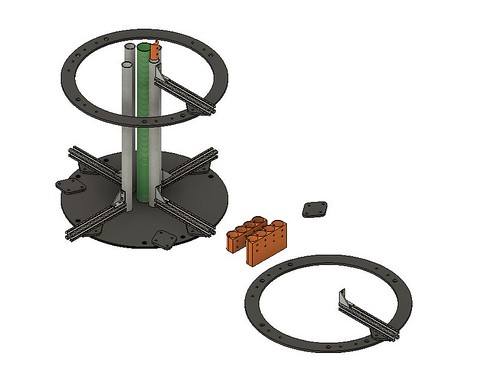

Question: Are you considering using PTFE (Teflon) wear strips on the vertical guides to reduce friction on the airframe?I'm far enough on the launch tower that I am convinced it is going to work. Here is the CAD rendering of all parts. The orange parts are nut holders and drill guides, and were 3D printed. The steel parts were all done by a laser cutting service. There is nothing revolutionary in the design. I was able to refine a few things by getting an up close look at some nice towers at Airfest the last couple years.

I've also attached the CAD file in .step format for anyone interested. If you view the file, forgive my ham-handed method of creating things...I'm self taught, and it shows.

Honestly, if you want something similar to this you should just buy the one Chris from APE sells...WAY less work, and unless you get a screaming deal on laser cutting as I did, probably cheaper too. I like to make things, and am generally a glutton for punishment, so I went for a ground up tower.

Enter your email address to join: