Brainlord Mesomorph

Well-Known Member

- Joined

- Apr 2, 2018

- Messages

- 266

- Reaction score

- 26

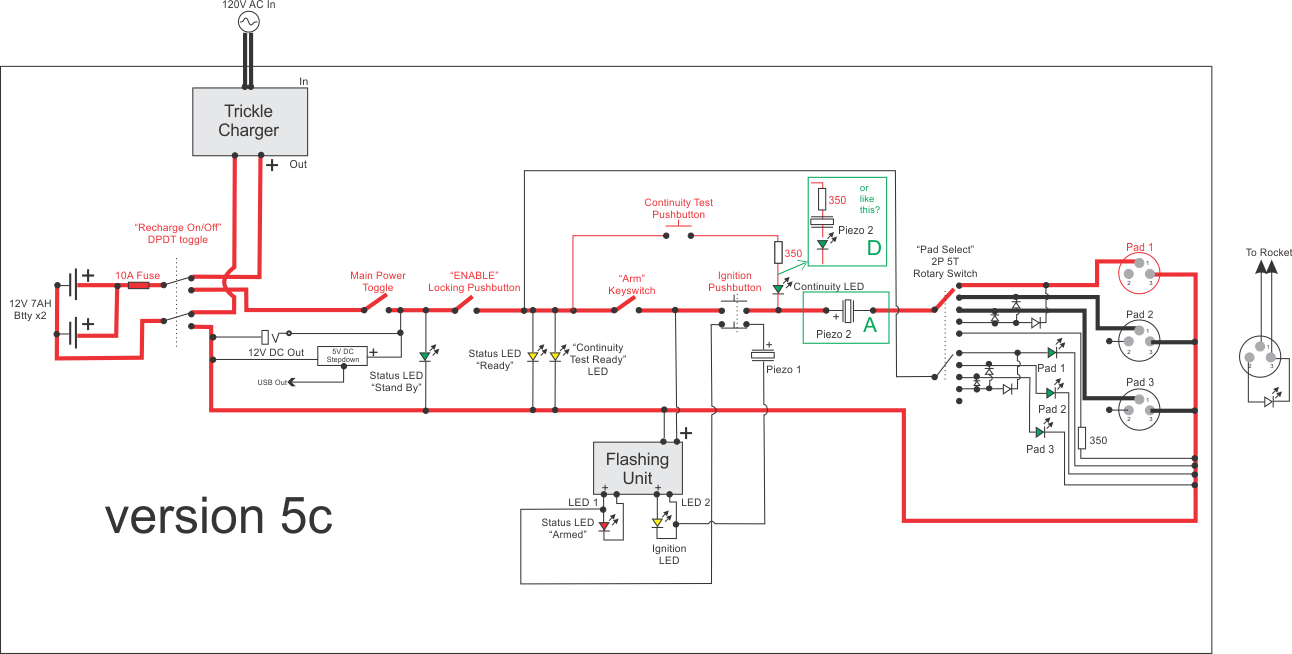

The 1st one is it! No, you won't fry the piezo. C? will work; B2 won't! No, C? won't short out the continuity test. Yes, you will get a light and beep. If you use B2, you will only get the forward voltage drop across the diode to power the piezo, and besides, it doesn't make sense to do it that way.

OK, maybe I'm not using the right words. C may not "short" the continuity test, per se, but getting a light and a beep w/o igniter continuity makes the test invalid and moot.

And version A just looks so incongruous.

A large portion of this thread is guys telling me to use the right (i.e. heavy 16 AWG) wire for this. Esp for the "high power" side of the circuit. The leads on this buzzer are like hair! If I have to place it in the middle of the high power circuit like that, I'm very tempted to cut open the plastic case on this thing and replace the leads w/ at least 22 AWG.

and aren't I getting a forward voltage drop to power the piezo, no matter what I do (A, B2, or C) ?

I love the Fawlty Towers dig! Classic!

I didn't mean it as a "dig" I just meant "Yes!, I know...."