dr wogz

Fly caster

Another thread on AV bays (the all-thread thread) got me thinking. Thinking about my L2 build, and the AV bay Ill soon be putting together.

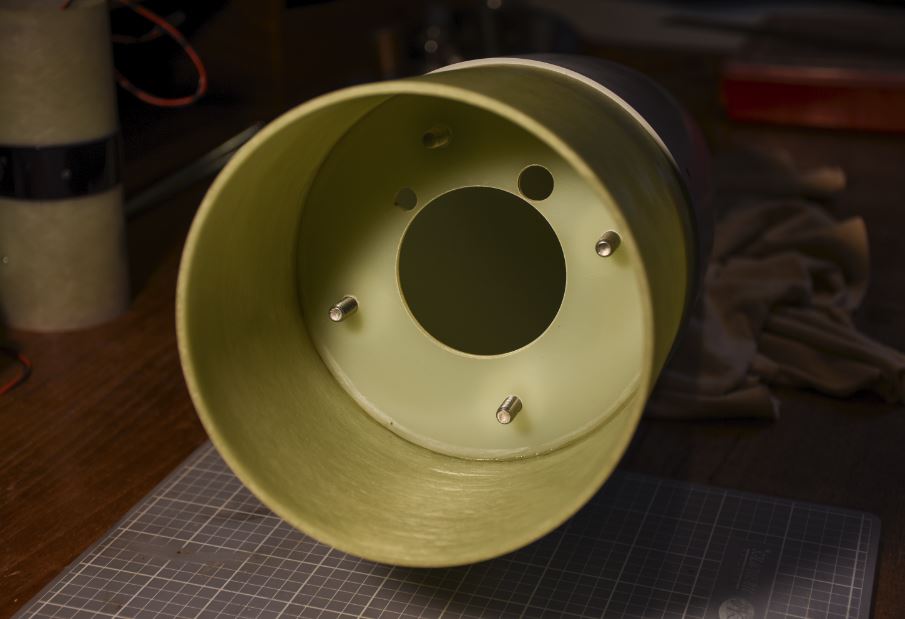

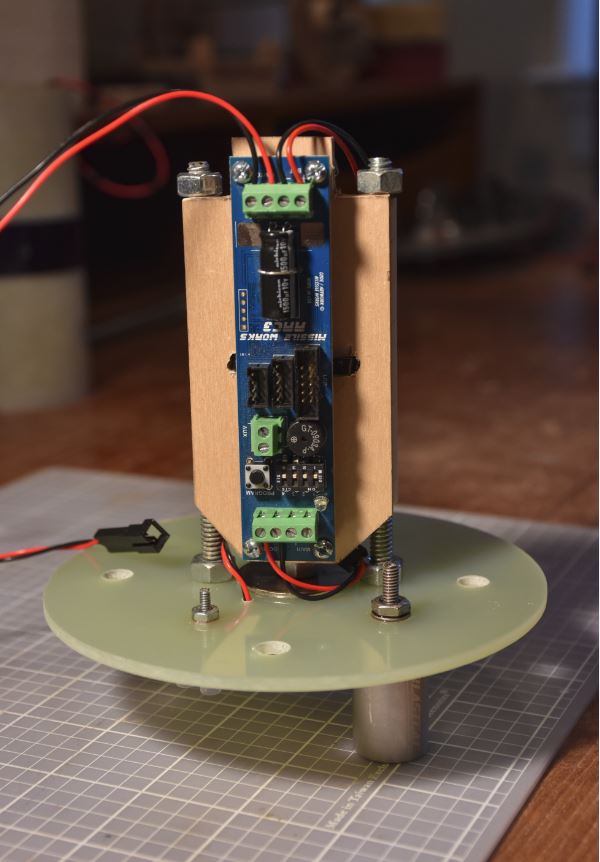

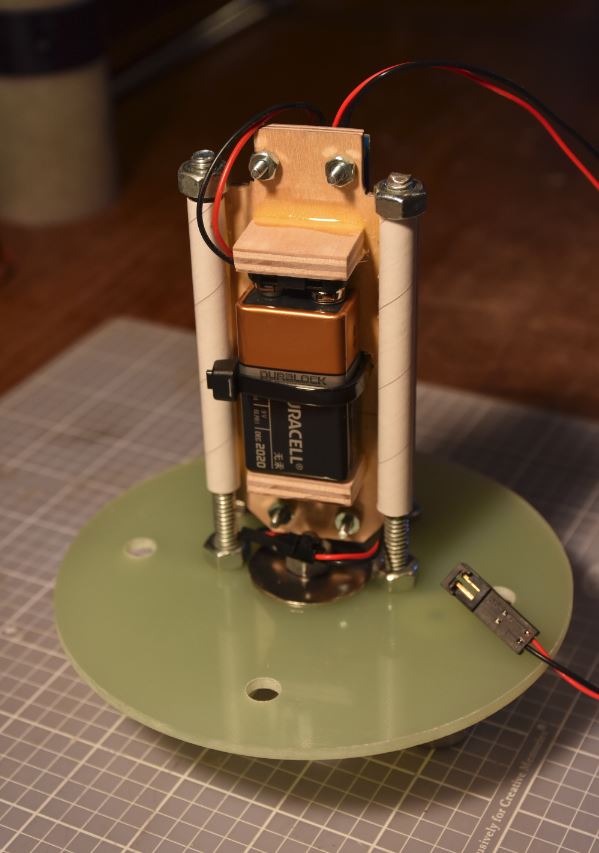

I had planned to build a standard style AV bay: AV tube (coupler material) internal & external bulk plates on each end (to make the can), 2 lengths of all-thread to hold it together, and either eye bolts or U bolts for cord attachments..

But as someone in the other thread mentioned, why not glue a bulkhead into the AV bay tube, and have the other end removable. Why do they both need to be removable? And to further that, why not have the removable one fit inside the AV bay tube, and fasten to a ring or support inside the tube, like we do for NC mounted AV bays? (Although there isnt much savings doing it that way.. Except a reduced access due the securing brackets or ring..)

And, is the band around the AV necessary? (The piece of BT fitted about the AV bay) I understand it to be used to stop the AV bay sliding up & down inside the BTs.. But it is typically secured to the upper BT with either buttons or screws. So, my thought is to just use screws (into blind nuts secured inside the AV tube) to secure it to the upper BT. As long as the holes all line up, I see no real issue..

My intent is to use whats supplied in the kit already (Madcow Super DX3) to minimize extra purchases. I plan to use the coupler as the AV bay (as described above) and need only buy and extra two bulk plates. (heck, I can cut these myself!) Obviously some threaded rod & other bits of hardware are needed to bring it all together

Comments?

I had planned to build a standard style AV bay: AV tube (coupler material) internal & external bulk plates on each end (to make the can), 2 lengths of all-thread to hold it together, and either eye bolts or U bolts for cord attachments..

But as someone in the other thread mentioned, why not glue a bulkhead into the AV bay tube, and have the other end removable. Why do they both need to be removable? And to further that, why not have the removable one fit inside the AV bay tube, and fasten to a ring or support inside the tube, like we do for NC mounted AV bays? (Although there isnt much savings doing it that way.. Except a reduced access due the securing brackets or ring..)

And, is the band around the AV necessary? (The piece of BT fitted about the AV bay) I understand it to be used to stop the AV bay sliding up & down inside the BTs.. But it is typically secured to the upper BT with either buttons or screws. So, my thought is to just use screws (into blind nuts secured inside the AV tube) to secure it to the upper BT. As long as the holes all line up, I see no real issue..

My intent is to use whats supplied in the kit already (Madcow Super DX3) to minimize extra purchases. I plan to use the coupler as the AV bay (as described above) and need only buy and extra two bulk plates. (heck, I can cut these myself!) Obviously some threaded rod & other bits of hardware are needed to bring it all together

Comments?