bobby_hamill

Well-Known Member

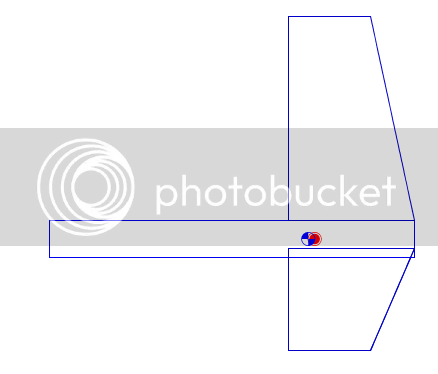

I hope to be doing 3 different up scales of some Estes kits to 4 inch diameter phenolic air frames

These will be for sport flying NOT for scale

would you use Birch Plywood or G10 to prevent fin breakage . The up scales will be using only 38mm motors

Birch Plywood or G10 ?

Thank You for your input

Bobby

These will be for sport flying NOT for scale

would you use Birch Plywood or G10 to prevent fin breakage . The up scales will be using only 38mm motors

Birch Plywood or G10 ?

Thank You for your input

Bobby