daviesca14

New Member

- Joined

- Nov 7, 2016

- Messages

- 3

- Reaction score

- 0

Anyone have any tips on learning how to cut a star grain?

Taking a solid grain and coring a star through it. Similar to what they do in commercial motors.

I know Loki uses a mandral-

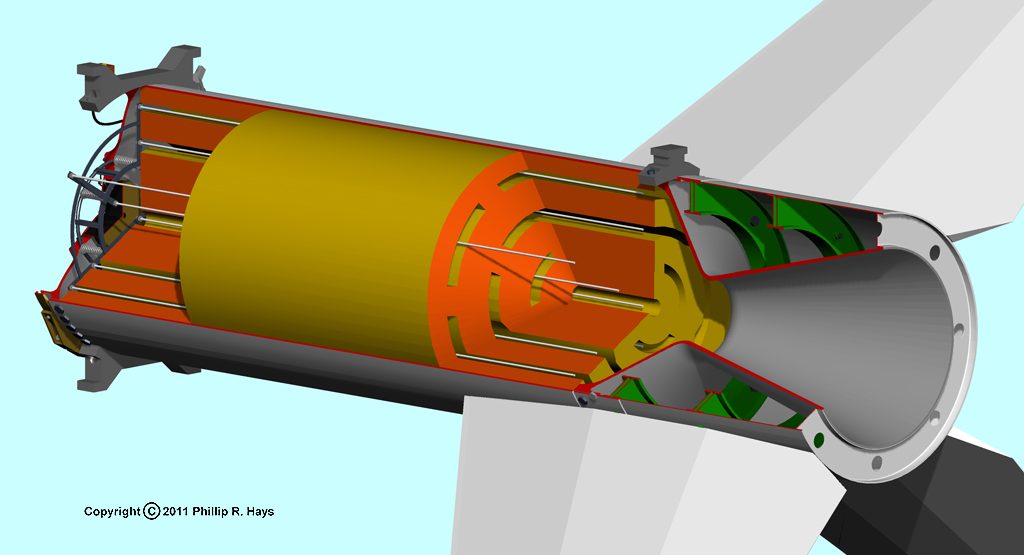

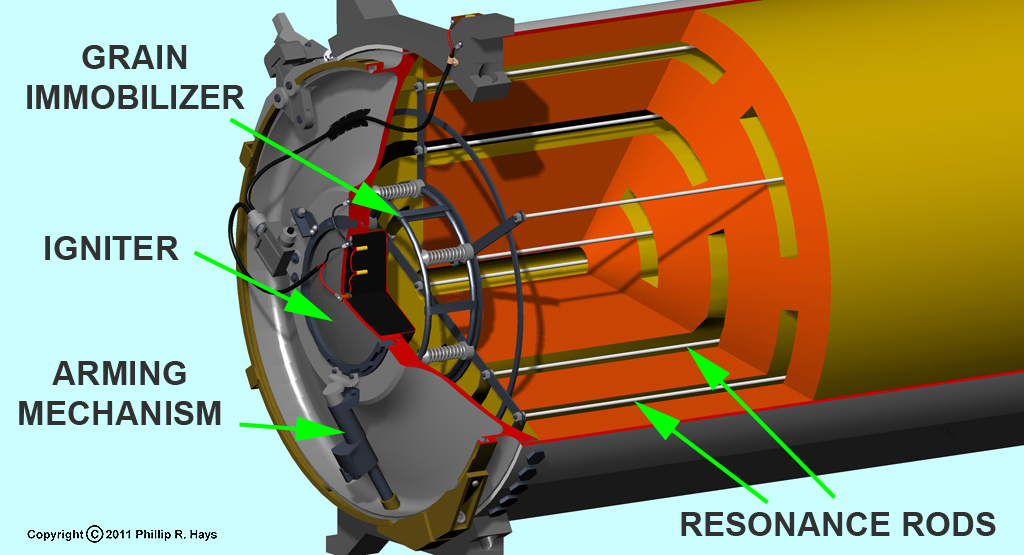

I know I've seen this before- which motor is this?

Just had to look that one up. Glad I did.:If you want to see an interesting core configuration, look up the booster of a Talos missile. That must have been fun to cast!

I know Loki uses a mandral-

It's tapered-

Enter your email address to join: