Very nice project.

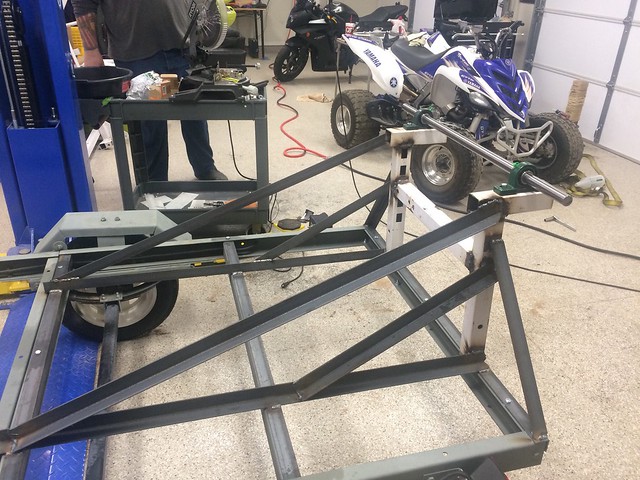

Seeing the photo, with the end of a disassembled 60 foot tower sticking out from the back of a trailer, I wanted to relate an incident that happened to Chris Taylor a few years ago.

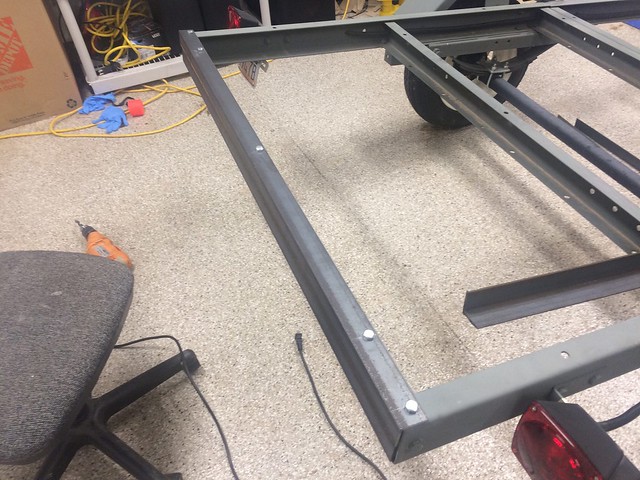

He had a very small utility trailer, sort of like the one below.

He was towing it using a small car. He did not have a lot of stuff piled on top of it, the profile was sort of low.

While he was driving back from the field one day, and slowing at na intersection. Apparently the vehicle behind him was tailgating and perhaps the driver’s seat and vehicle’s hood was “tall”, I do not recall him saying what the other vehicle was. Anyway, they ran into the back of his trailer and damaged it very badly, he was unable to drive with it. It was their fault 100%. But a contributing factor was that they didn’t see the end of the trailer… maybe not even see the trailer at all.

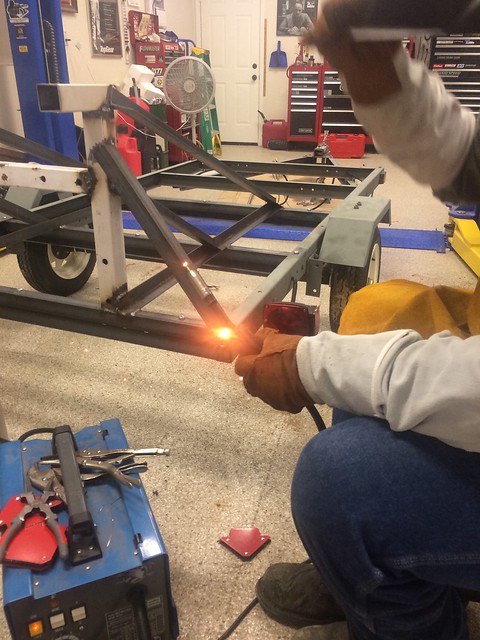

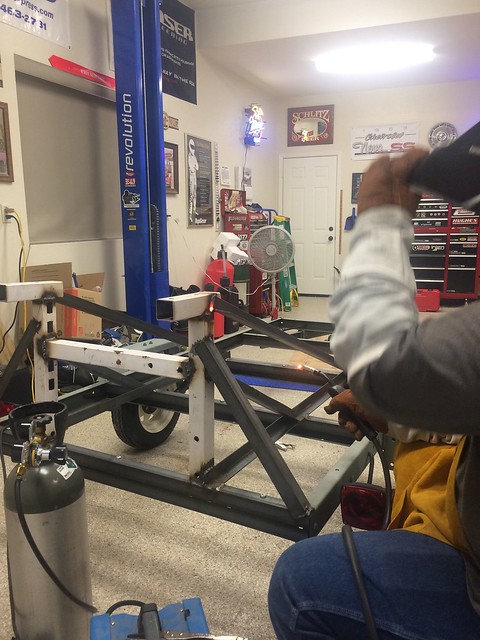

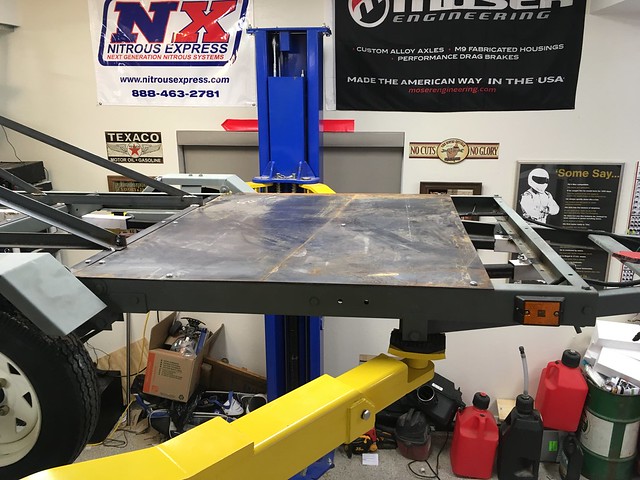

I know this is a longer ad bigger trailer than what Chris had. But still, I mention this to recommend adding some sort of high visibility posts, ideally an extra pair of taillights, that would be high enough for a driver behind to see them more easily. Could perhaps be designed to be hinged so they could be moved out of the way if they interfered with the use of the pad. Now if the pad sticks out for the back like the first photo, then that would ideally use something attached to the end of the pad itself, removed once at the launch site

Sort of the same reason why so many vehicles now have a duplicate brake light in in the rear window or high up on the back of tall SUV’s and such, in case the following driver is too close to see the brake lights closer to the ground.

No guarantee that some stupid driver would not run into it anyway, but a pro-active form of “defensive driving” to add some extra lighting (or something of high visibility) higher up.

- George Gassaway