- Joined

- Nov 8, 2015

- Messages

- 1,401

- Reaction score

- 78

Wow Ken. I totally missed this thread. Well done! Similar to how we used to wrap feathers on shafts to get a good spin. Launch looked really nice. Again, well done!!!

Wow Ken. I totally missed this thread. Well done! Similar to how we used to wrap feathers on shafts to get a good spin. Launch looked really nice. Again, well done!!!

Great job. Keep building them bigger and better!

A spinoff from one in the list....Thrill Drill

Right Round Baby

Something about this one also looks dangerous...so that means I should upscale, right? :wink:

I bet a 29mm version would like the E16 and F15s!

I think so too! Then if that works well, it can maybe scream on some AP motors.

Maybe I'll go 29mm with a large streamer. The areas I launch from are very tricky, so having a rocket that flies up straight and comes down precisely is a gem.

54mm later on?

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet

I'd LOVE to! However that would most likely be in steps...first 24/29mm, then (not necessarily in order and some can be combined): HP, Fiberglass, CF, 38mm, 54mm, DD, Ball bearings (?). I'd really like to eventually have a 54mm FG/CF with ball bearings on the lower spiral fin can and a mounted camera.

One of the tricky parts right now is figuring a good fin material for HP fins...should be flexible enough for the spiral but strong for HP and also be able to glue in place quickly and firmly. Many choices out there to test including Styrene, PVC, Fiberglass, Kydex, Lexan and others. Anyone got any suggestions?

Oh dont worry, it will happen sooner or later >

More likely next year since I have a number of other projects that are fairly high priority commitments, but you never know...

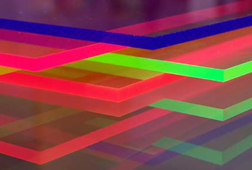

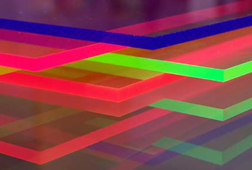

Been looking through the options for "plastic" fins on a 29-38mm and one that would be really cool if it works is this...

Would be awesome for night launches with a glow stick taped to the base of each fin!

Unfortunately it's acrylic, which is fragile and prone to breakage from what I've heard; however I'm hoping that being curved and shorter than normal fins, they will be stronger...we'll see. I'm having a lot of trouble finding suitable flexible plastic for upscales. Fiberglass may be an option, but I'm not sure if it can be twisted enough (even with heat) and that is a lot of testing as well.

I've also started looking at possibly doing a Fiberglass 29mm main tube with 38mm roller-bearing shroud extending up to a 38mm chute compartment so I can go HP and use a Chute release. Sounds simple, right?However I'll likely just make a 29mm cardboard one next...smaller steps!

That would be awesome, as far as using fiberglass, its as simple as using a curved surface instead of a flat one to get that curved fin. No need to hasle with heating it to get it to bend.

Best save that stuff for later lad. I think its better to start off with paper and balsa to see what works and what doesnt.

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet

Ken. What you want to do is come up with some sort of Helical jig like we used to use in Archery. Would make getting the fins on a snap. While this isn't as strong of a helical as you have, it represents what I mean..one of the old Jo Jan helical fletching jigs.

View attachment 293604

I'd LOVE to! However that would most likely be in steps...first 24/29mm, then (not necessarily in order and some can be combined): HP, Fiberglass, CF, 38mm, 54mm, DD, Ball bearings (?). I'd really like to eventually have a 54mm FG/CF with ball bearings on the lower spiral fin can and a mounted camera.

On the LP version, did you do anything special to enable the fin "can" (really stretching the term here) to spin smoothly on the main BT?

I'm also trying (unsuccessfully) to mindsim what is the effect (other than coolness) of having the fin can spin on its own rather than just letting the whole rocket spin...

Well, you're assuming I'm planning on laying the fiberglass myself, but that isn't the case (at least not in the near future). I was thinking of cutting it from sheet and bending/twisting it to shape...same as I'm doing now with the small rockets and same as I was thinking for acrylic/lexan/kydex fins.

For you it likely isn't a problem to do it in FG or CF...and that would be really cool.

BTW - Can you heat, twist and set CF sheet?

Maybe someone can correct me on this, but maybe if you get it to its Tg you can warp it, but in the process might ruin it. I do know for a fact there is a resin that you can heat up and shape it. I dont know where you can get it, however.

I bet someone can 3D print me a curved dome to make the curved fins. It would be so easy to lay a fiberglass or carbon sheet.

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet

I saw some CF sheet on ebay (listed as 100% carbon fiber...is there a way to verify?) and the pic shows it molded into a bike seat; however I'm not sure about if that is actually possible and the implication that you can cover or make a bike with it is ridiculous:

If it wasn't so costly, I would buy it to test with, but for now, it's another back burner project.

When it comes to those dealers you definitely got to watch out. It may be 100% carbon, but it could be a weak modulus carbon that just sucks.

I can make a thin sheet that you should be able to bend, however you will have to hold it in place while you are bonding it to the body tube.

Even thin fiberglass should be able to be bent and when it comes down to it, I'd use fiberglass over carbon, because its cheaper. Thats of course if you want carbon strength and looks.

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet

Ah, thanks for the heads up Alex!Also thanks for the option of custom thin sheet...I may discuss that with you at a later time if/when I go CF on this baby. For now, I want to focus more on developing a good fin pattern and the paper ones, then the cheaper plastic first before going CF since it would be quite a shame to waste such beautiful material! :no:

Gotta head off for a family hike, but I'll update later today - I got in 3 launches in earlier this morning...stay tuned! :grin:

Enter your email address to join: