Sevian

Well-Known Member

- Joined

- Dec 28, 2013

- Messages

- 55

- Reaction score

- 0

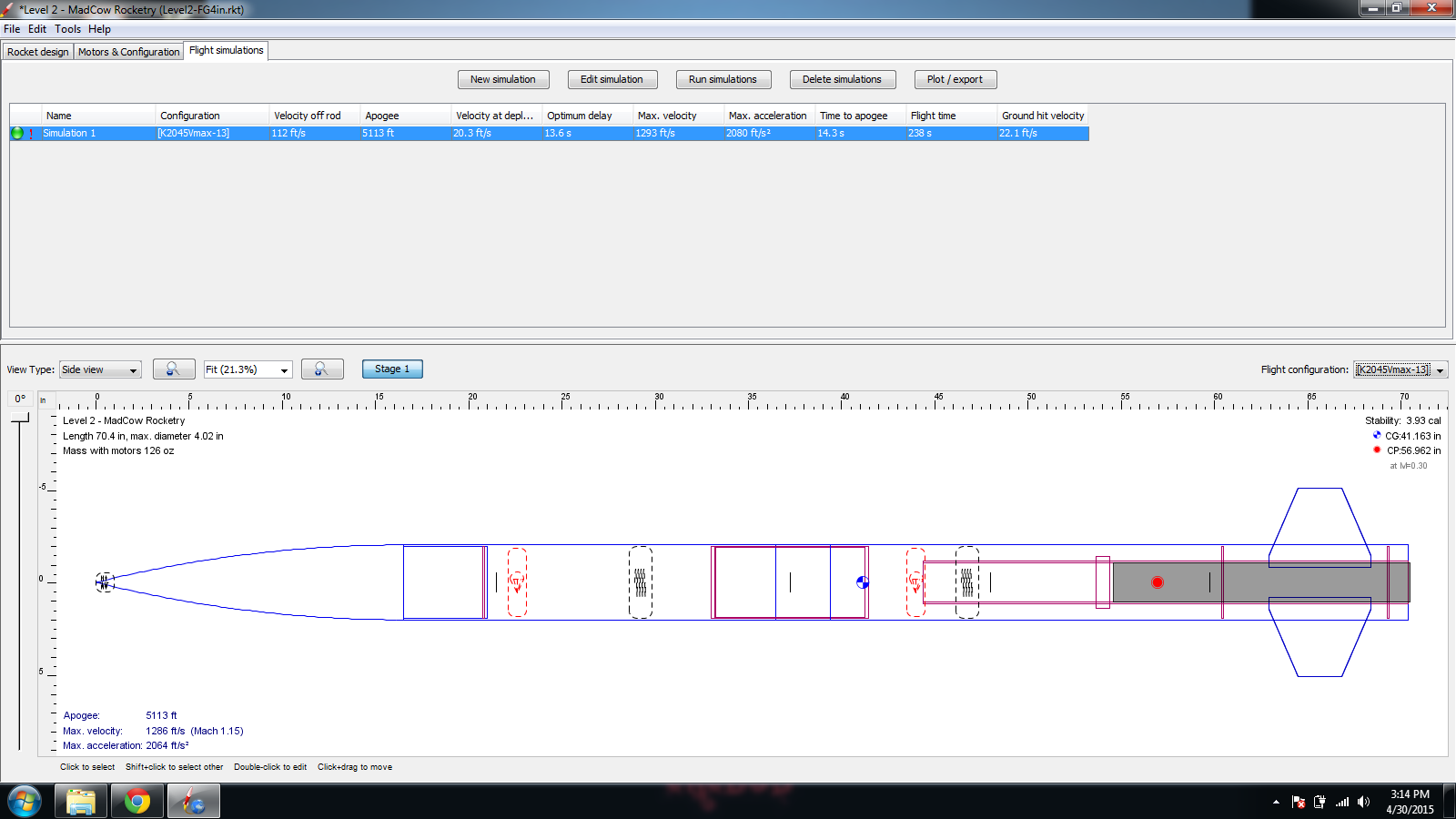

Hello there! I figured my first build thread should be for my Level 2, which I'm going to do with the Level 2 rocket from Madcow.

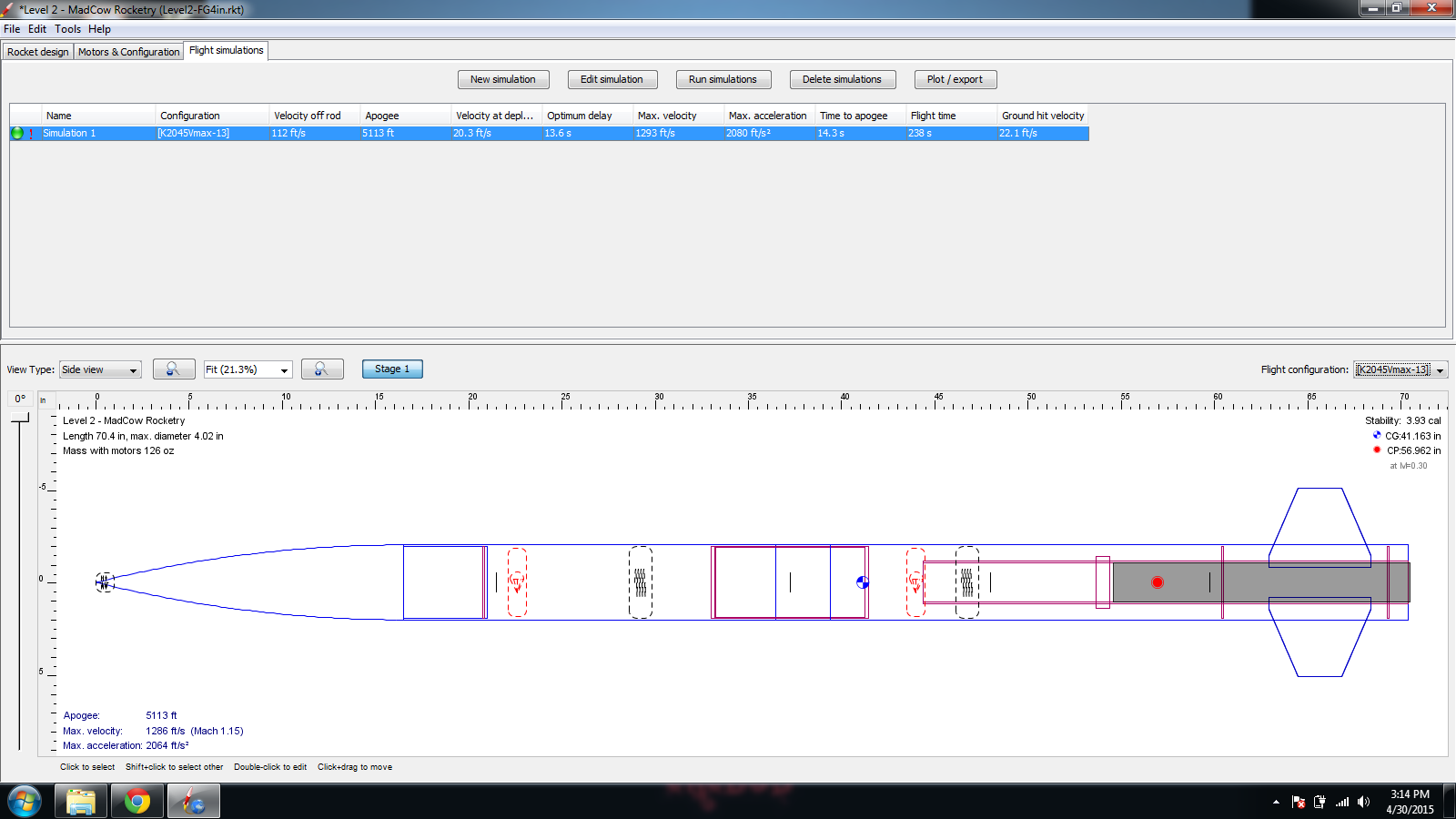

All parts have been sanded and will be dry fitting shortly, just a quick question about OR sim I ran with it. I'm planning to cert with a J285, but the eventual "big" flight will be with a K2045.

I ran the simulation at first with a 17 second delay, said the the velocity was too high at 70ft/s. Optimal was 13, so I edited it for a delay of 13 and it came out correct. Does that seem right? Here is the screen cap of the sim:

Any comments or concerns will always be appreciated, more build pictures coming soon!

All parts have been sanded and will be dry fitting shortly, just a quick question about OR sim I ran with it. I'm planning to cert with a J285, but the eventual "big" flight will be with a K2045.

I ran the simulation at first with a 17 second delay, said the the velocity was too high at 70ft/s. Optimal was 13, so I edited it for a delay of 13 and it came out correct. Does that seem right? Here is the screen cap of the sim:

Any comments or concerns will always be appreciated, more build pictures coming soon!