One of the topics I'm gonna hit at the NARHAMS meeting this weekend is shaping glider wings. For most small gliders, you can get them to fly fine without doing much to the wings. I've seen gliders with square edges fly fine, and simply rounding the leading and trailing edges can get you a glider that will perform ok for sport flying. For contest flying, or if you want to get the best flights that you can, you need to step up and put an airfoil on your wing.

Here is one method for taking that square slab of balsa and turning it into a nice airfoil. This technique relies on an essential tool- the razor plane.

Here is my plane from Master Airscrew:

Basically it's a small hand planer with a razor blade that sticks out of a slot on the bottom of the tool. You slide it along the surface of your wood and it takes off a sliver.

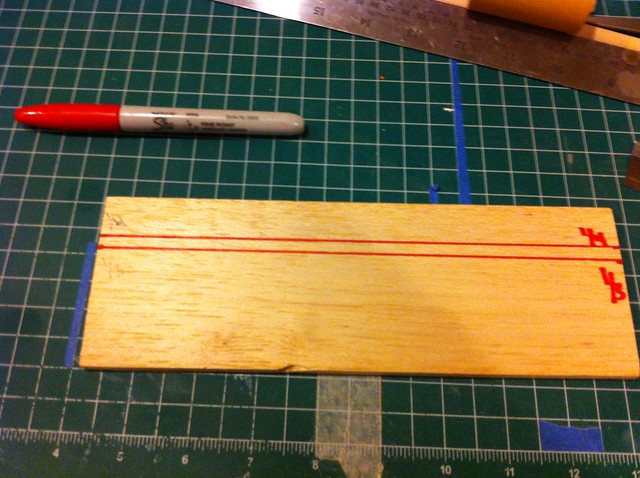

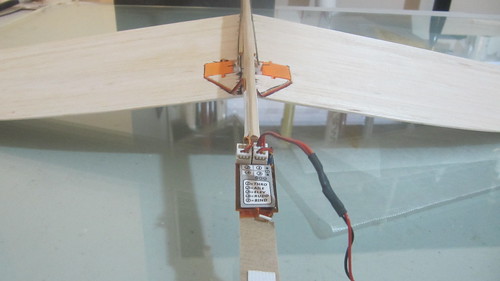

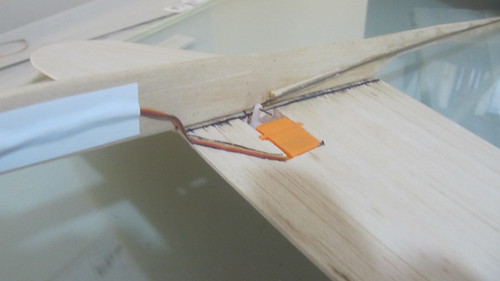

I'm not making anything fancy for this model, just a flat bottom airfoil that looks about right. The general rule is that you want the high point of your airfoil (maximum thickness) about 1/4 to 1/3 of the way back from the leading edge of your wing. In my examples I'm using a 3"x9" piece of 1/4" thick balsa. Here I've measured out the 1/4 and 1/3 chord lines on the blank:

And a close up:

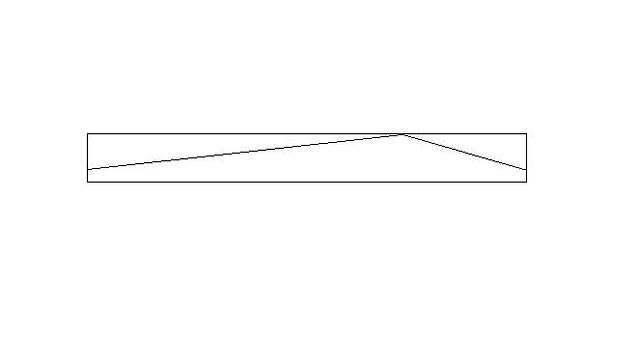

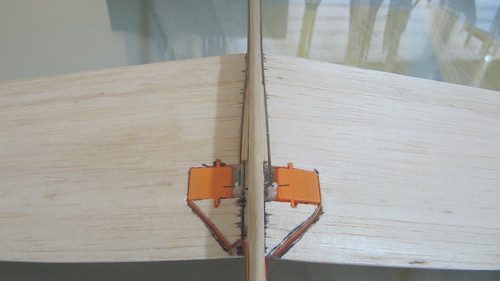

So the max thickness of my airfoil is going to be somewhere between those lines, and the leading edge will curve down pretty quickly while the trailing edge will taper back to a narrow thickness. Here's what I'll be shooting for, so you can see how much wood needs to be removed:

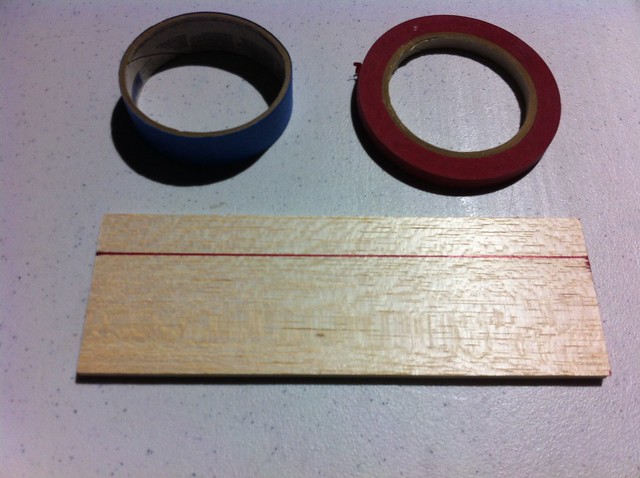

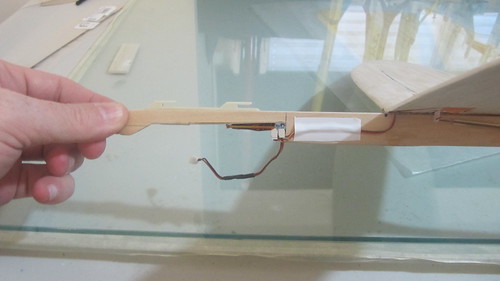

I like to start with the leading edge, so put your blank on a flat surface, and with the razor plane at an angle, start to shave away the wood that you don't want. I'm just knocking off the corners at this point:

Soon you'll start to gather a little pile of shavings:

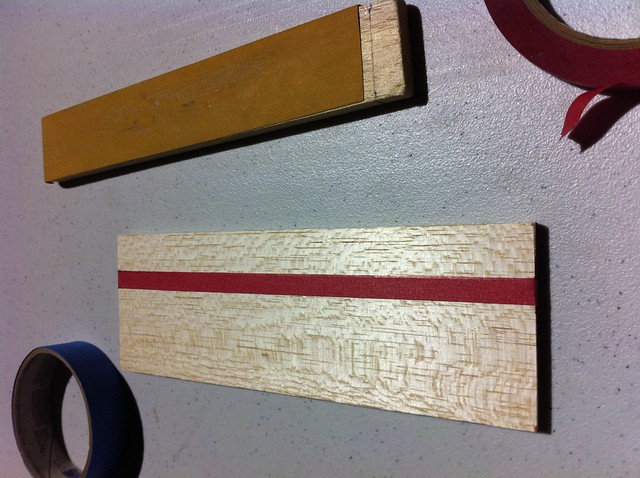

To do the trailing edge, flip your blank around and repeat. You'll end up with a bigger pile of shavings:

I can't say enough how much easier it is to work with a razor plane that has a nice sharp blade. You will end up changing it often, and if you're into this sort of thing, using a sharpening stone to keep the edge nice.

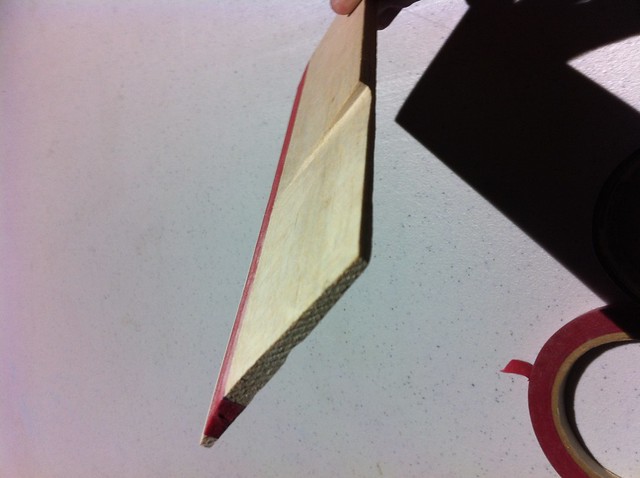

After getting rid of all that excess wood, you'll end up with an airfoil:

I have a little finish sanding to do, mainly dressing up the leading edge and thinning the trailing edge a little bit, but most of the work was done by the plane.

kj