ECayemberg

Well-Known Member

- Joined

- Jan 21, 2009

- Messages

- 2,877

- Reaction score

- 850

Please enjoy this abbreviated build thread of our Dangerous Dave 11.5" V-2 (who here remembers Dangerous Dave Gawlik?). This is not intended to be a full build thread, just cover a few highlights before it hits the pad.

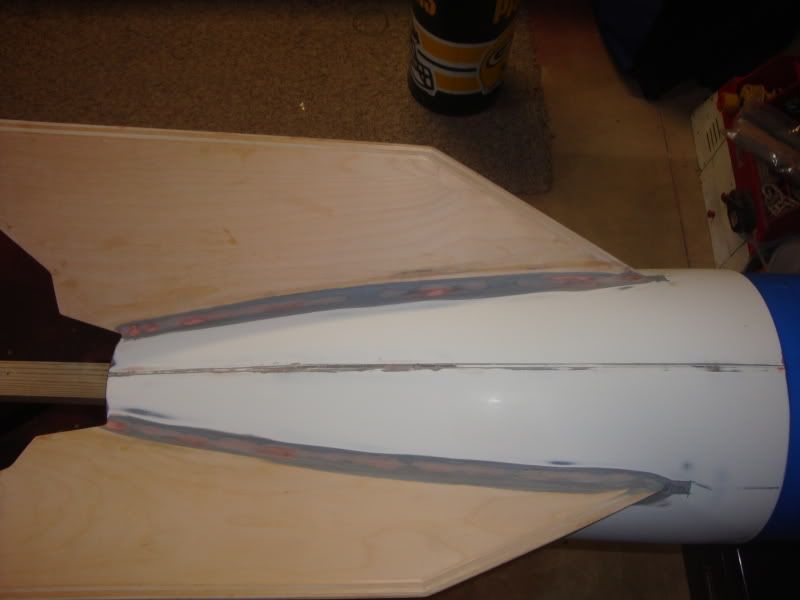

The Kit was originally available from Dangerous Dave in the early 90's; we purchased it second hand last year. The kit consists of a gray gelcoated 3:1 ogive glass nosecone, 3:1 ogive tailcone, ply fins, PML phenolic airframe, and a 4" carpet tube style motor mount.

The Plan is to complete the project and fly at Tripoli Wisconsin's July 23rd launch at the infamous Bong Recreation Area in Southeastern Wisconsin. Motor will be the Aerotech M1939W.

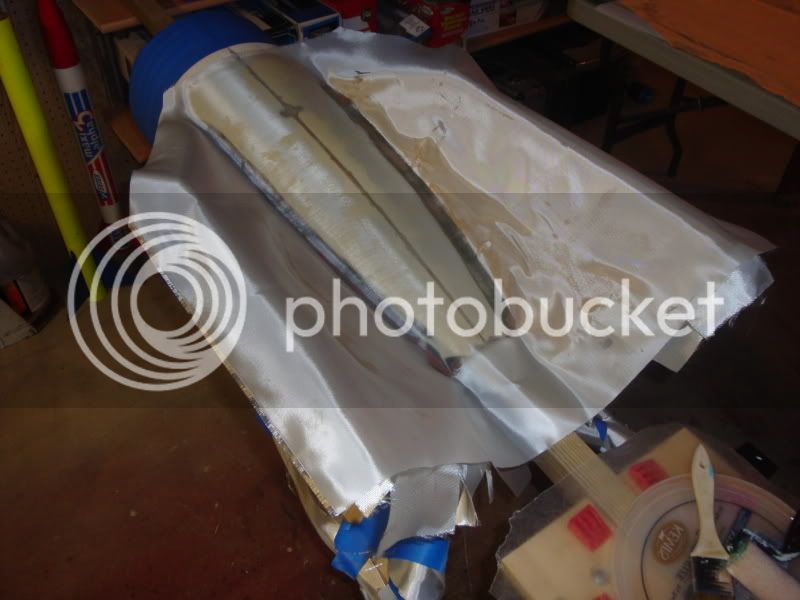

The Team consists of Tom, Kevin, Brandon, and Eric Cayemberg. Tom (my Dad) is responsible for general deconstruction and construction, electronics, transport, and painting. Kevin (my uncle, Tom's brother) is in charge of recovery gear for the big turd. Brandon (my 2 year old son) is in charge of reminding me to work fast as I don't have much free time with him around and another munchkin on the way in a few weeks. Eric (me) is in charge of filling, sanding, glassing, priming, and propulsion.

On to construction!

The Kit was originally available from Dangerous Dave in the early 90's; we purchased it second hand last year. The kit consists of a gray gelcoated 3:1 ogive glass nosecone, 3:1 ogive tailcone, ply fins, PML phenolic airframe, and a 4" carpet tube style motor mount.

The Plan is to complete the project and fly at Tripoli Wisconsin's July 23rd launch at the infamous Bong Recreation Area in Southeastern Wisconsin. Motor will be the Aerotech M1939W.

The Team consists of Tom, Kevin, Brandon, and Eric Cayemberg. Tom (my Dad) is responsible for general deconstruction and construction, electronics, transport, and painting. Kevin (my uncle, Tom's brother) is in charge of recovery gear for the big turd. Brandon (my 2 year old son) is in charge of reminding me to work fast as I don't have much free time with him around and another munchkin on the way in a few weeks. Eric (me) is in charge of filling, sanding, glassing, priming, and propulsion.

On to construction!