Estesbasher

Well-Known Member

- Joined

- Mar 29, 2013

- Messages

- 373

- Reaction score

- 48

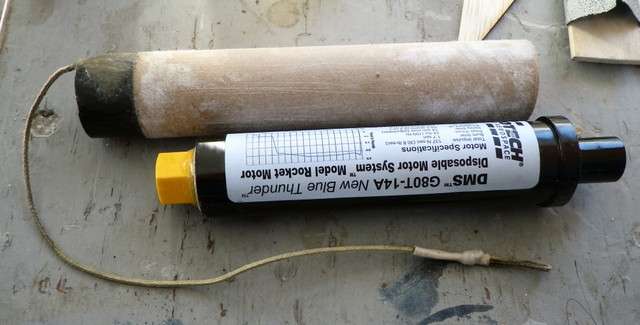

I thought some of you guys and gals would like to see how you could build a mach buster using parts from balsa machine. With one of the estes BT-55 cones, And yes some of you low power guys will like this build.No fiber glass or carbon fiber will be used on this build.Other than g-10 for the fins. It will be kept lite, I don't care how high this rocket goes. I just want to see how fast I can get one to go on the G-80.

The rocket is built and the weight comes in at 4.7 oz.

so I'll post pictures and explain what I've done and why. because you know after all it is rocket science.

so I'll post pictures and explain what I've done and why. because you know after all it is rocket science.

Spec.

17.5" long

29mm.

4.7 oz.

.049 G-10 fins

Root cord. 4.5"

Span.1.25"

The rocket is built and the weight comes in at 4.7 oz.

Spec.

17.5" long

29mm.

4.7 oz.

.049 G-10 fins

Root cord. 4.5"

Span.1.25"

Last edited: