lcorinth

Well-Known Member

- Joined

- Aug 5, 2014

- Messages

- 1,022

- Reaction score

- 46

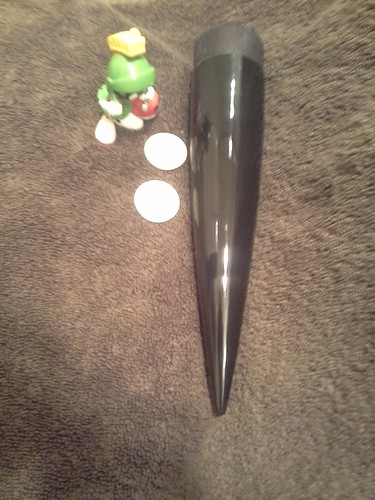

I have some Tamiya plastic putty which I intended to use to fill the seam on nose cones. I'm working on a rocket right now, and the seam, instead of being a lowered, divot-like area, is actually a little ridge, where the two halves of the nose don't quite meet just perfectly. I'm not sure putty is the answer for finishing this nose, since I'm dealing with a raised area.

I thought of sanding the ridge down. I tried it on the shoulder of the nose, but it seemed to scratch the plastic. However, I do have some higher grit papers - 600 and 800. I tested the 800 on the shoulder, and again, had scratches, but they seem pretty tiny, so I'm wondering if they won't show through after I prime the rocket. Then again, maybe 800 is too fine to actually take this tiny ridge off.

Anybody have any insight on this? I want this rocket to look really nice. Thanks!

I thought of sanding the ridge down. I tried it on the shoulder of the nose, but it seemed to scratch the plastic. However, I do have some higher grit papers - 600 and 800. I tested the 800 on the shoulder, and again, had scratches, but they seem pretty tiny, so I'm wondering if they won't show through after I prime the rocket. Then again, maybe 800 is too fine to actually take this tiny ridge off.

Anybody have any insight on this? I want this rocket to look really nice. Thanks!