Agatheron

Well-Known Member

- Joined

- Jun 2, 2014

- Messages

- 153

- Reaction score

- 0

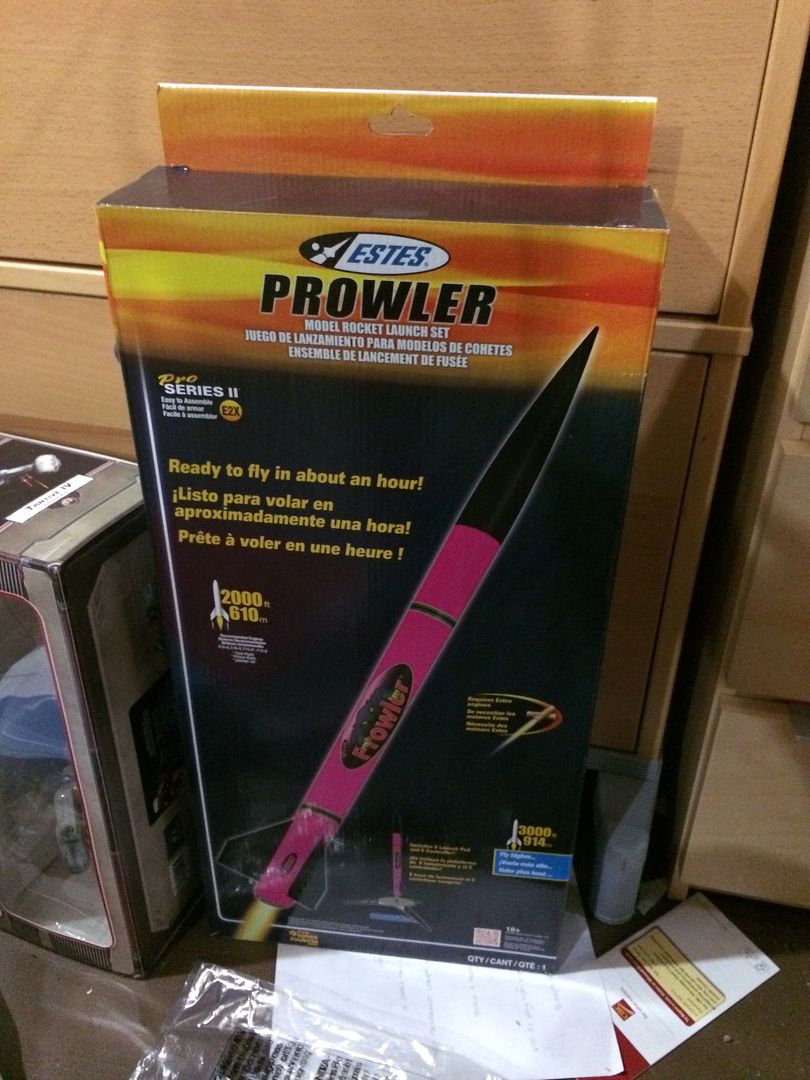

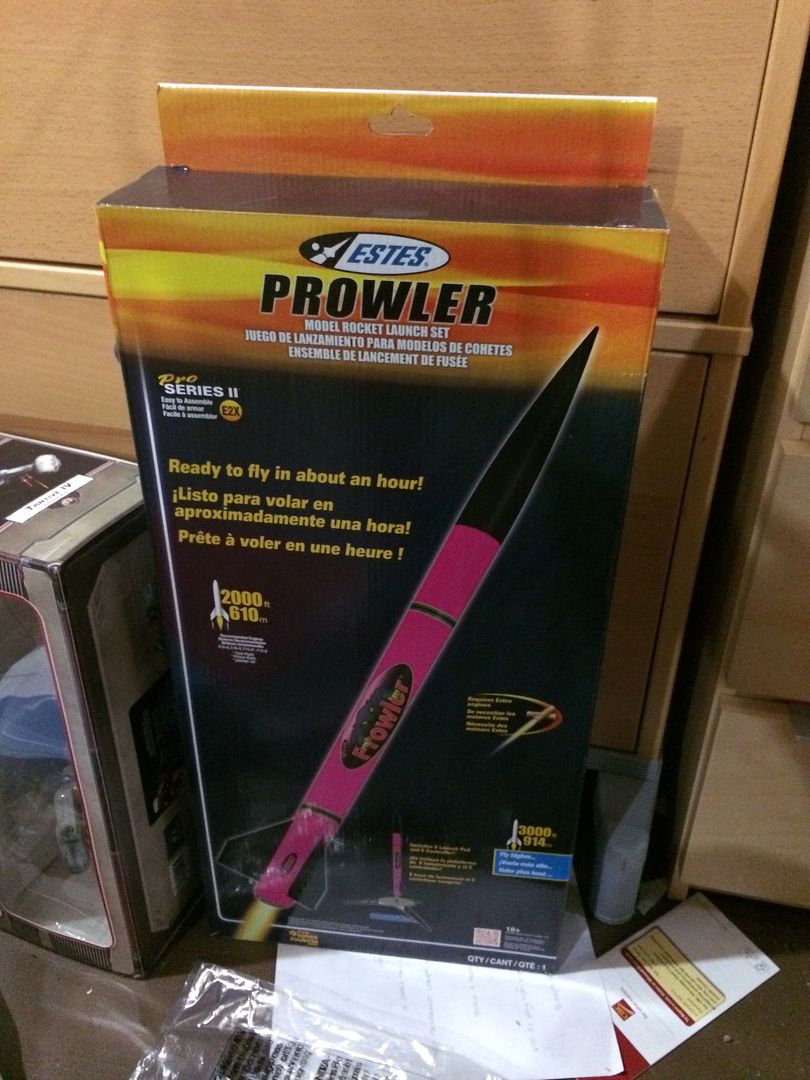

For the longest while I was convinced that the Estes Prowler Pro Series II starter kit wasn't available in Canada. Much to my surprise, after mentioning it to my local hobby shop, they called me with it now being in stock. I'm basically building this one concurrently with the Maxi-Alpha 3 in another nearby thread. However, since this kit is E2X, I am not planning to paint it, at least not yet. My daughter quite likes the hot pink look of it, and wants to keep that colour.

Here's the box it comes in:

And the parts to the Rocket itself:

In terms of size, it is thinner than the Maxi-Alpha 3. (2" vs. 2.6"), but it going to be about about a half-inch taller once it's all assembled.

In terms of assembly, my plan is to use primarily epoxy to put it together. The shock cord is attached to the interior of the tube with a plastic clip that glues in rather than the folded paper typical of lower-power rockets. I have some kevlar line, a few quick releases, and a few swivels, so I may modify the build to give this a bit more internal strength. I worry about the stock shock cord and zippers...

Any input would be appreciated, but at the same time this may also be helpful for those looking at a kit like this. I know it is an E2X, but it will be helpful for me to learn the basics of mid-power.

Here's the box it comes in:

And the parts to the Rocket itself:

In terms of size, it is thinner than the Maxi-Alpha 3. (2" vs. 2.6"), but it going to be about about a half-inch taller once it's all assembled.

In terms of assembly, my plan is to use primarily epoxy to put it together. The shock cord is attached to the interior of the tube with a plastic clip that glues in rather than the folded paper typical of lower-power rockets. I have some kevlar line, a few quick releases, and a few swivels, so I may modify the build to give this a bit more internal strength. I worry about the stock shock cord and zippers...

Any input would be appreciated, but at the same time this may also be helpful for those looking at a kit like this. I know it is an E2X, but it will be helpful for me to learn the basics of mid-power.