- Joined

- Mar 27, 2013

- Messages

- 22,535

- Reaction score

- 14,942

Through-The-Wall fins are guaranteed to eliminate cockeyed fins... And in the English language, a double positive statement can NEVER form a negative statement... Yeah, RIGHT! :eyeroll:

Several of my older two stage builds have pairs of beautifully aligned fins, and one cockeyed fin. This, of course makes the perfectly aligned fins on the booster look wrong, as the odd one screams out "LOOK AT ME!!! I'm messed up"

So, for my latest trick, I give you...

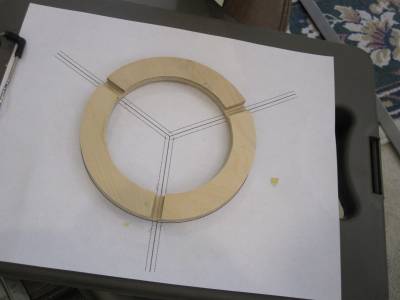

The TTW fins should have tabs that come in contact w/the motor tube, or upon failing that, contact with a forward centering ring. I say "a forward centering ring" instead of "the forward centering ring" because with Estes PSII kits there are three centering rings, and the tabs come in contact with the middle and aft centering ring. If the tab doesn't come in contact with either the motor tube or a forward centering ring, this won't help you.

First I determine which centering ring will be the aft one, and sand it so it will easily slip into place without much effort, then I set it aside.

I glue my forward centering ring and my middle centering rings in place first by tacking them with medium CA (DON'T use thin CA, as it sets too quickly, and is far too easy to mess up with). If I need to adjust one, I can cut the tack away, re-position it, and tack it again. Once I'm happy with that, I'm using epoxy to cement them firmly to the motor tube. As the tack will hold them in place well enough as the epoxy cures. While the epoxy cures, I go ahead and tack the motor mount in place (again with CA). I leave off the rear centering ring for now. If I'm happy with the location of the mount, I then tack my fins in place. One drop of medium CA just forward of the slot on the exterior of the body tube, and one aft of the slot. I position my fin, and when happy with it, set it with the accelerator (Insta-Set). I next tack (one drop of medium CA) the fin tab to the motor tube. Once all the fins are in place, I then use epoxy to lock them firmly in place with internal fillets (on the inside of the body tube, and to the motor tube. The epoxy will also lock the fin tab to the centering ring, and the centering ring to the body tube.

When all the fins are filleted, I apply epoxy on the rear of the fin tabs, on the inside of the body tube just behind the fin tabs, and the outside of the motor tube. I then slide the aft centering ring in place, and epoxy it from the outside. If there is a forward centering ring, I'll epoxy it after the rest of the assembly is well on the way to curing.

[EDIT] When you're working in and around the fillets, take care to only get the glue on the parts of the MMT and the BT that you want. IF YOU'RE NOT CAREFUL, you may end up with lumps that have to be sanded/cut away for the CR and motor retainer to fit, adding to the work you need to do.

Mind you, if the center of the fin tab is slotted to allow fin tabs to lock the middle centering ring in place (e.g. Estes' Mega Der Red Max), you may need to leave the forward-most centering ring off until you epoxy the fins in place. This could be a lot more difficult, but I feel it could be done.

[EDIT] Here's the link to my technique for papering fins (No Runs, No Drips, No Foul Language).

Several of my older two stage builds have pairs of beautifully aligned fins, and one cockeyed fin. This, of course makes the perfectly aligned fins on the booster look wrong, as the odd one screams out "LOOK AT ME!!! I'm messed up"

So, for my latest trick, I give you...

How to get TTW fins right the first time (or fix them if you foul up)

The TTW fins should have tabs that come in contact w/the motor tube, or upon failing that, contact with a forward centering ring. I say "a forward centering ring" instead of "the forward centering ring" because with Estes PSII kits there are three centering rings, and the tabs come in contact with the middle and aft centering ring. If the tab doesn't come in contact with either the motor tube or a forward centering ring, this won't help you.

First I determine which centering ring will be the aft one, and sand it so it will easily slip into place without much effort, then I set it aside.

I glue my forward centering ring and my middle centering rings in place first by tacking them with medium CA (DON'T use thin CA, as it sets too quickly, and is far too easy to mess up with). If I need to adjust one, I can cut the tack away, re-position it, and tack it again. Once I'm happy with that, I'm using epoxy to cement them firmly to the motor tube. As the tack will hold them in place well enough as the epoxy cures. While the epoxy cures, I go ahead and tack the motor mount in place (again with CA). I leave off the rear centering ring for now. If I'm happy with the location of the mount, I then tack my fins in place. One drop of medium CA just forward of the slot on the exterior of the body tube, and one aft of the slot. I position my fin, and when happy with it, set it with the accelerator (Insta-Set). I next tack (one drop of medium CA) the fin tab to the motor tube. Once all the fins are in place, I then use epoxy to lock them firmly in place with internal fillets (on the inside of the body tube, and to the motor tube. The epoxy will also lock the fin tab to the centering ring, and the centering ring to the body tube.

When all the fins are filleted, I apply epoxy on the rear of the fin tabs, on the inside of the body tube just behind the fin tabs, and the outside of the motor tube. I then slide the aft centering ring in place, and epoxy it from the outside. If there is a forward centering ring, I'll epoxy it after the rest of the assembly is well on the way to curing.

[EDIT] When you're working in and around the fillets, take care to only get the glue on the parts of the MMT and the BT that you want. IF YOU'RE NOT CAREFUL, you may end up with lumps that have to be sanded/cut away for the CR and motor retainer to fit, adding to the work you need to do.

The nice thing about this method, is that should a fin set in an awkward position, you only need to cut the tack and try again until you get it right. This is also speeding up my construction, as I'm now no longer having to wait for epoxy to cure before gluing my fins in.

Mind you, if the center of the fin tab is slotted to allow fin tabs to lock the middle centering ring in place (e.g. Estes' Mega Der Red Max), you may need to leave the forward-most centering ring off until you epoxy the fins in place. This could be a lot more difficult, but I feel it could be done.

[EDIT] Here's the link to my technique for papering fins (No Runs, No Drips, No Foul Language).

Last edited: