Nathan

☢

- Joined

- Apr 19, 2012

- Messages

- 2,230

- Reaction score

- 755

My Porsche DX3 was damaged a couple of weeks ago when then upper and lower sections crashed together hard during parachute deployment. I just finished repairing it, and I took some pictures of the process.

The lower section got the most damage so I am only showing the repair of the lower section. The impact was hard enough to tear the cardboard tube. One of the fins also got slightly dinged up.

First step was to sand down the damaged area.

Then I did a repair job using Bondo Glazing and Spot Putty. I wouldn't want a body shop using this stuff on my car but it's great for rockets. This picture was after 3 coats of Bondo. After each coat I dry sanded with 600 grit. It may not look smooth from this picture but it is.

The texture of the Bondo will show through the paint unless it gets covered with primer. Here it is masked for primer.

I lightly sanded the primer with 400 grit and feathered the edges of the primered area so that there will be no visible ridges once it's repainted. This picture is with the rocket masked for spraying black. Notice that although only one fin was damaged, I am repainting both, to make the repair less visible.

I forgot to take a picture after spraying the black paint. Here it is after spraying black, waiting 3 days, and then wet sanding the repainted area with 2000 grit.

After polishing and waxing it's as good as new!

The only sign of the repair job is the barely visible paint edge just below the Porsche emblem.

The lower section got the most damage so I am only showing the repair of the lower section. The impact was hard enough to tear the cardboard tube. One of the fins also got slightly dinged up.

First step was to sand down the damaged area.

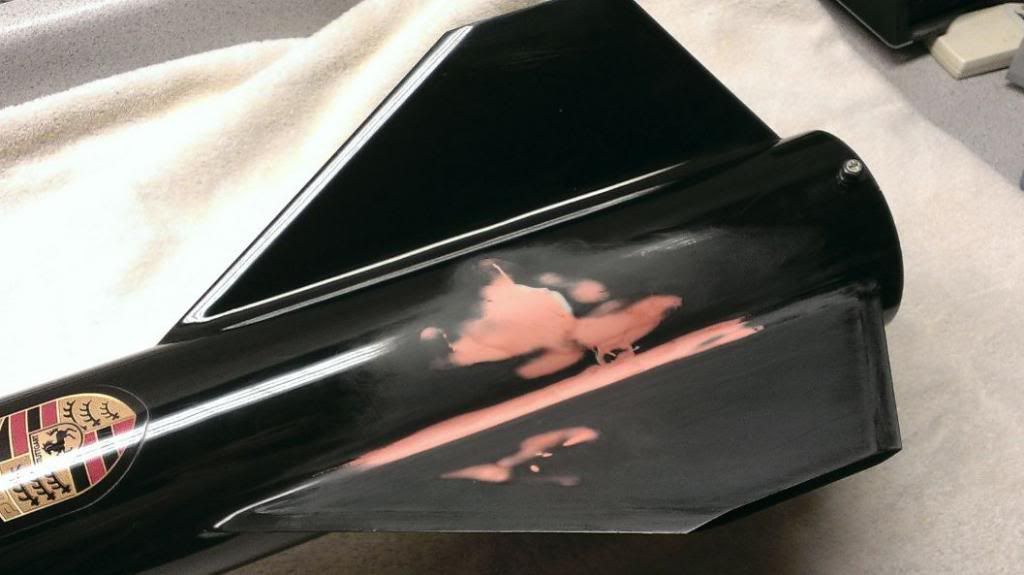

Then I did a repair job using Bondo Glazing and Spot Putty. I wouldn't want a body shop using this stuff on my car but it's great for rockets. This picture was after 3 coats of Bondo. After each coat I dry sanded with 600 grit. It may not look smooth from this picture but it is.

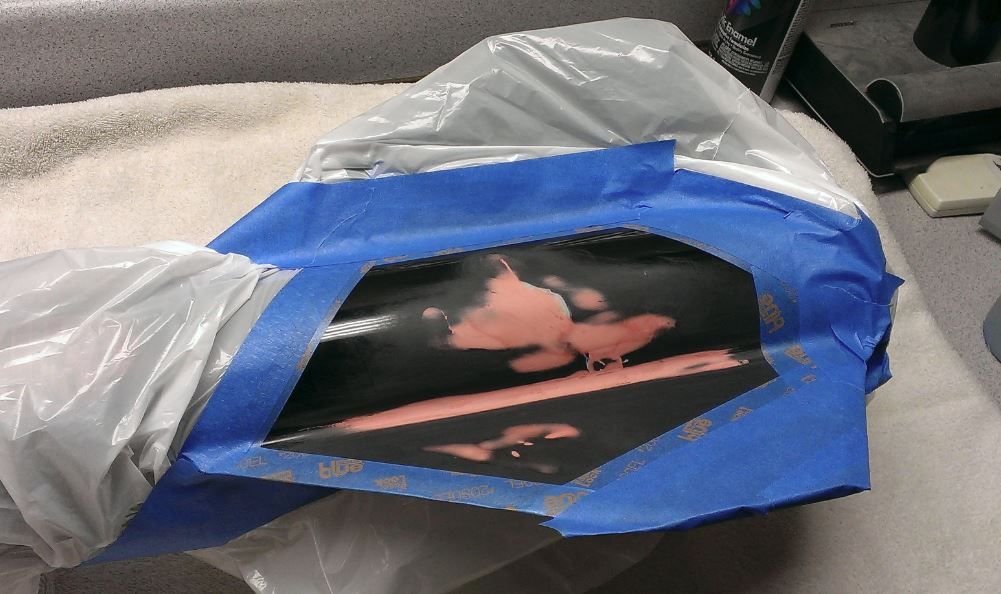

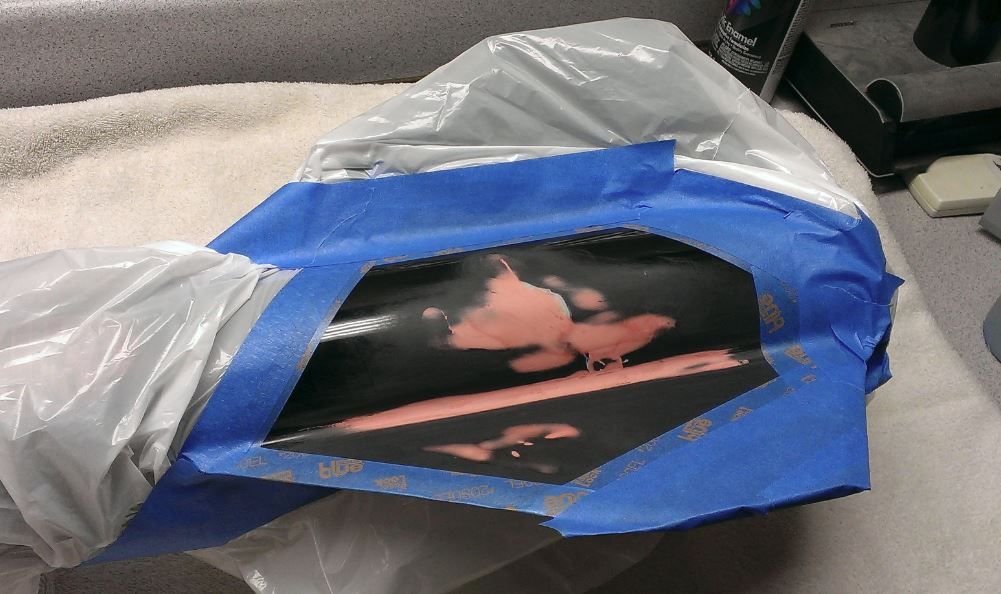

The texture of the Bondo will show through the paint unless it gets covered with primer. Here it is masked for primer.

I lightly sanded the primer with 400 grit and feathered the edges of the primered area so that there will be no visible ridges once it's repainted. This picture is with the rocket masked for spraying black. Notice that although only one fin was damaged, I am repainting both, to make the repair less visible.

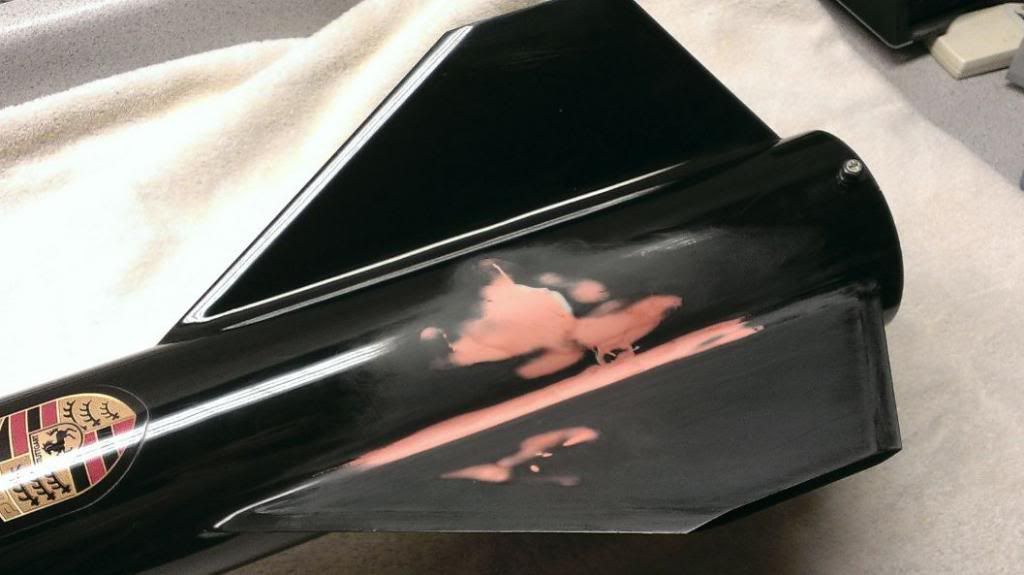

I forgot to take a picture after spraying the black paint. Here it is after spraying black, waiting 3 days, and then wet sanding the repainted area with 2000 grit.

After polishing and waxing it's as good as new!

The only sign of the repair job is the barely visible paint edge just below the Porsche emblem.