- Joined

- Mar 27, 2013

- Messages

- 22,537

- Reaction score

- 14,950

I've yet to get my hands on my D-Region Tomahawk (2 on order) but in reading Estes' instructions online, I found these instructions that make me feel like this is going to be a mess, and perhaps be unsafe even.

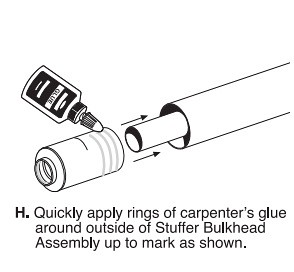

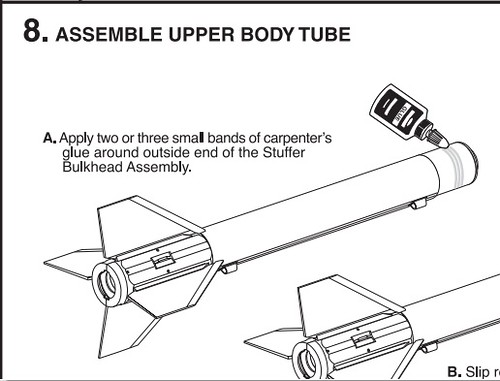

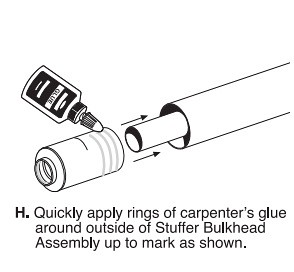

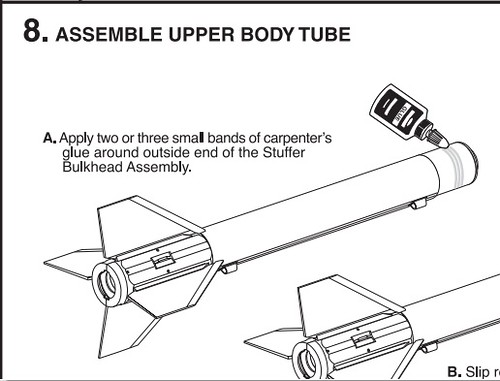

I've discovered in the past that a great way to mess up a build is by putting glue on the outside of something that slips inside of another. It pushes glue out (potentially onto your hand), and can mess up a finish. These are Steps "4H", and "8A".

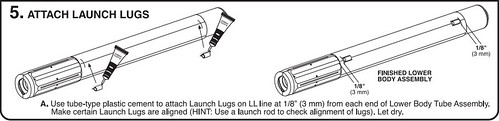

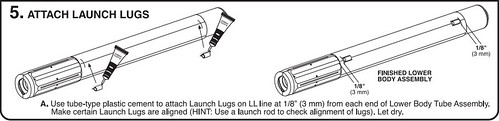

As for the Launch Lugs, tube-type plastic cement is a solvent dissolved into a plastic matrix. Upon application, it is designed to dissolve the surface of the part slightly, melting it, then the solvent evaporates off leaving a welded joint, or (such as on the inside of cardboard tubes) it will melt a plastic part slightly while absorbing a little into the rough cardboard surface before it sets. If the launch lugs, and outer body tube surface, are typical of Estes' products, they're not made from something that will react to (and thus bond with) the tube-type plastic cement given in the instructions. This is found in step "5"

Should the glue bonds fail under the stress of an E9-4 launch, that could cause the rocket to careen off course possibly into people (causing injury), or property (causing damage (to the rocket at least)). My Estes Gemini Titan (1978) kit lost much of it's plastic surface detail to the cement not bonding to the body tube (and it never flew once).

Feedback appreciated.

Jim

I've discovered in the past that a great way to mess up a build is by putting glue on the outside of something that slips inside of another. It pushes glue out (potentially onto your hand), and can mess up a finish. These are Steps "4H", and "8A".

As for the Launch Lugs, tube-type plastic cement is a solvent dissolved into a plastic matrix. Upon application, it is designed to dissolve the surface of the part slightly, melting it, then the solvent evaporates off leaving a welded joint, or (such as on the inside of cardboard tubes) it will melt a plastic part slightly while absorbing a little into the rough cardboard surface before it sets. If the launch lugs, and outer body tube surface, are typical of Estes' products, they're not made from something that will react to (and thus bond with) the tube-type plastic cement given in the instructions. This is found in step "5"

Should the glue bonds fail under the stress of an E9-4 launch, that could cause the rocket to careen off course possibly into people (causing injury), or property (causing damage (to the rocket at least)). My Estes Gemini Titan (1978) kit lost much of it's plastic surface detail to the cement not bonding to the body tube (and it never flew once).

Feedback appreciated.

Jim

Last edited: