TopRamen

SA-5

- Joined

- Aug 9, 2013

- Messages

- 9,955

- Reaction score

- 111

It starts with me being bored and trying my hand at making a Nose Cone out of the left over Tip of a Cone I Chopped up awhile back for a different Project. I was going to give up on it, but decided to throw caution to the Wind and go for it.

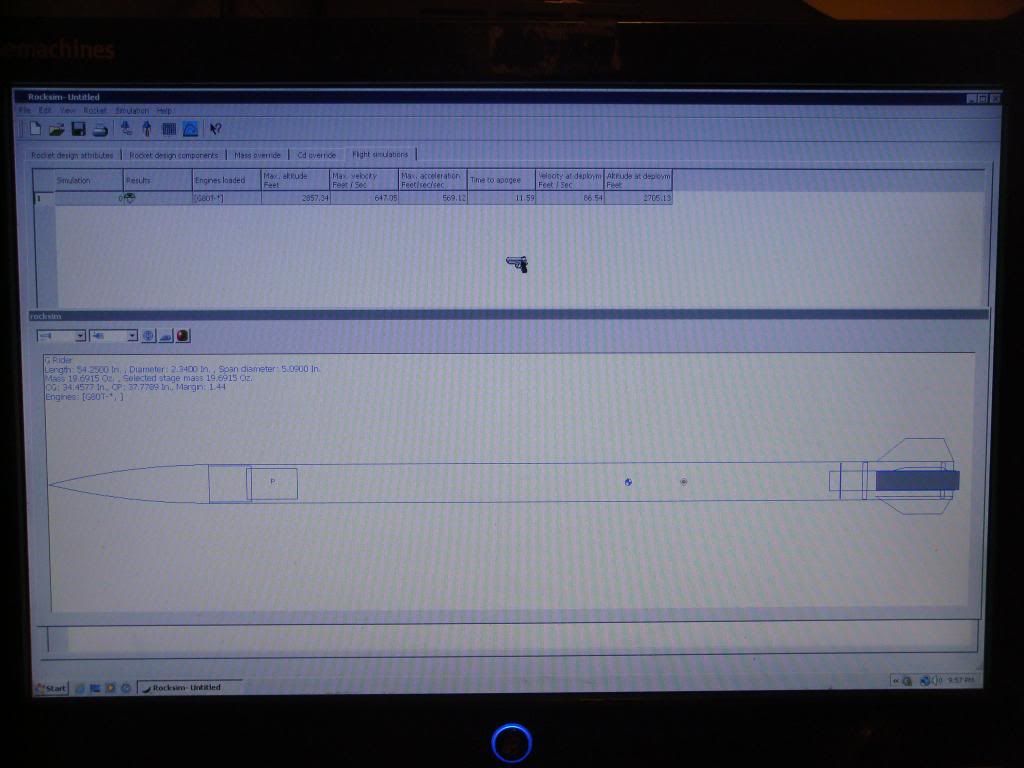

ETA: I likely will sim this now that it is taking shape.

Well, here we go!:

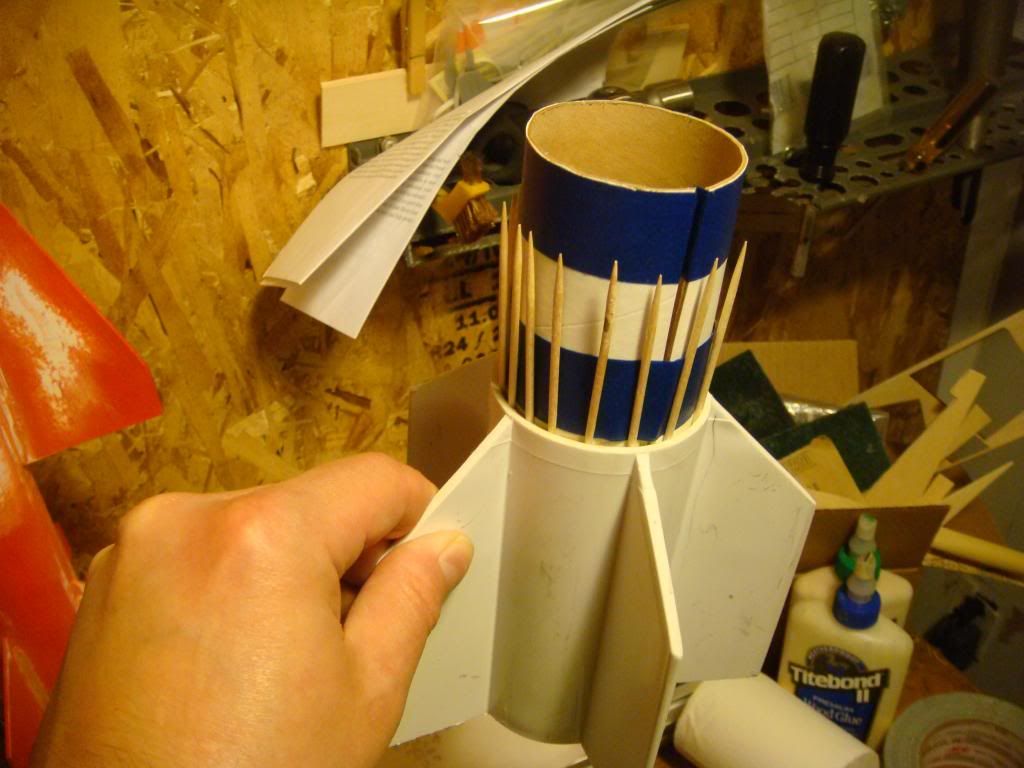

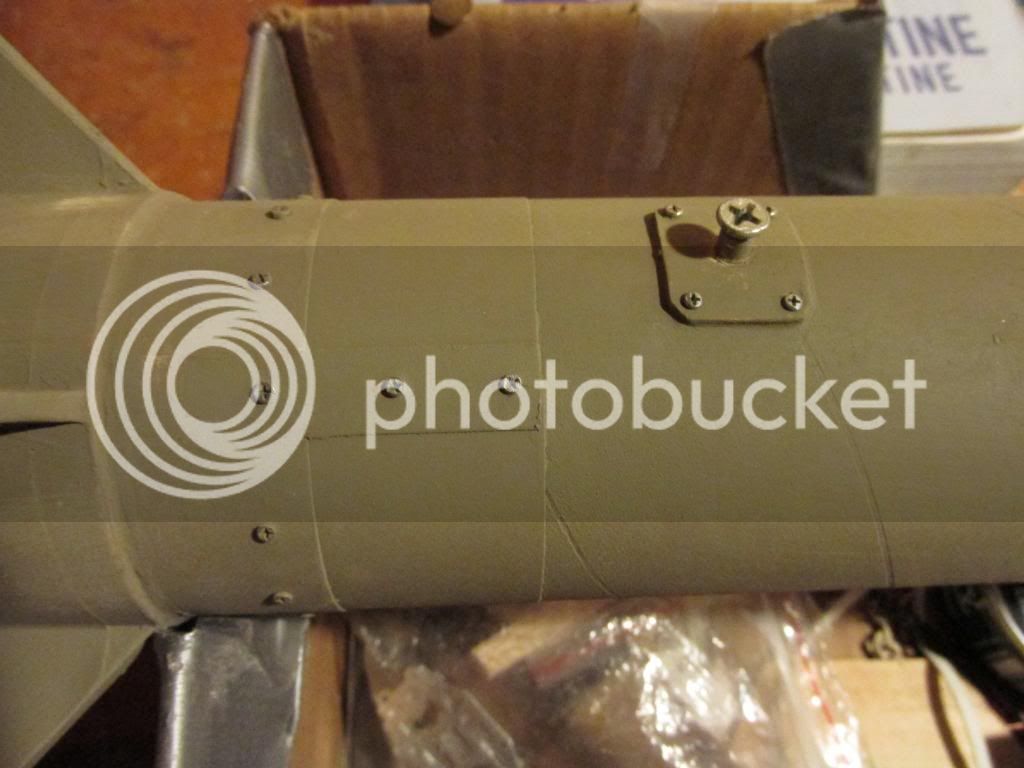

Started out with the tip of the old chopped up Cone. Rolled some 80lb. Card Stock around it and held it in place with some Tape to get the general Shape. I took the Cone out and tacked it in a few spots along the Seam with CA. I put a ring of CA around the Base of the small plastic Cone and slid the Paper Part on. Now, I slathered CA all over it, inside and out. When this dried, I trimmed the majority of the obvious excess. I then slathered it inside and out with 5 minute Epoxy. When that was dry, I added clippings of Paper to the inside with Titebond II Wood Glue to stiffen it. I had tried using a Cruciform of Balsa, but that warped it. The next Morning, I sanded the inside to even out the odd shapes of Paper I had fitted. Everything was stiff, so I trimmed some more, and sanded the Base til' it was even and concentric.:

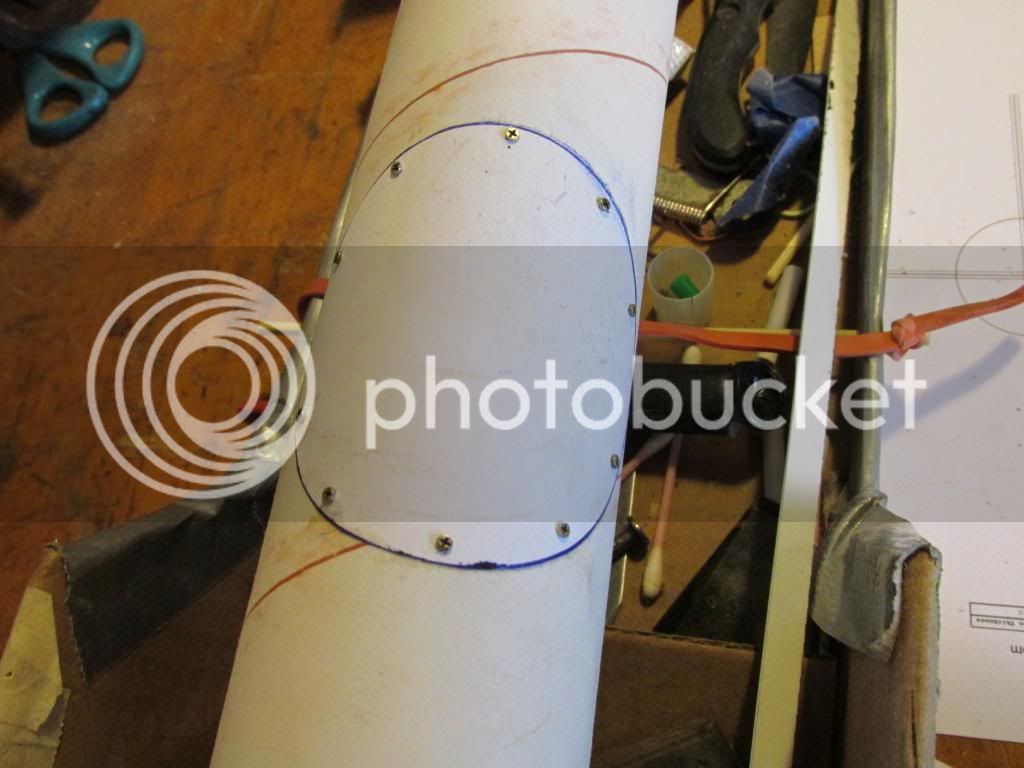

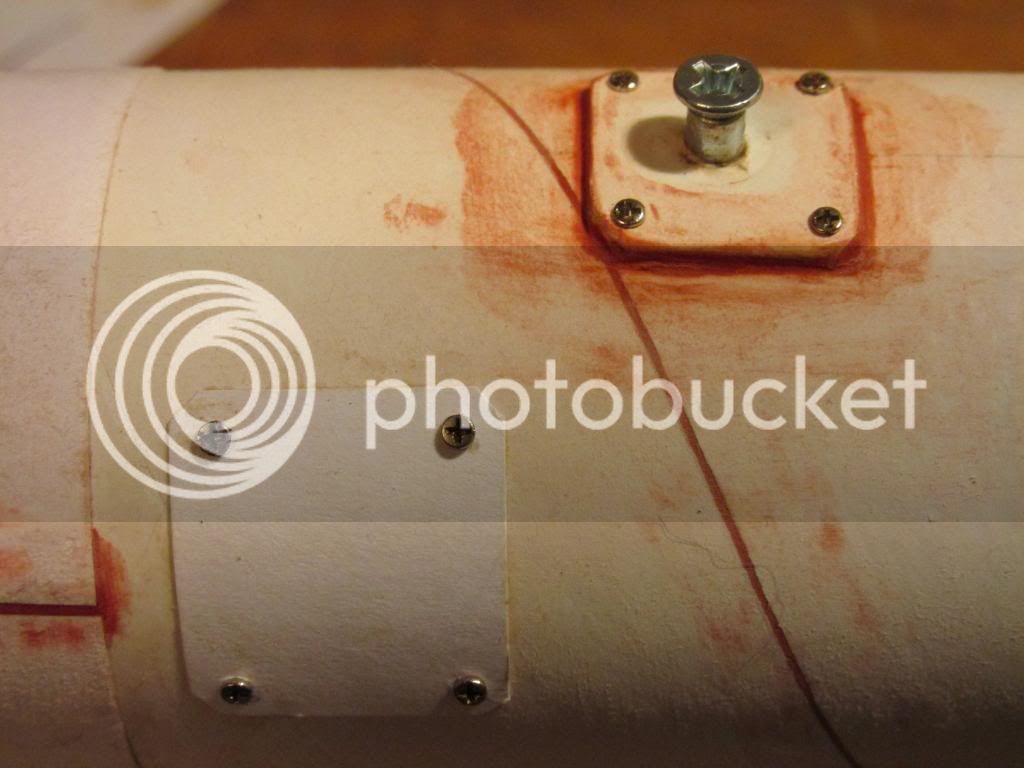

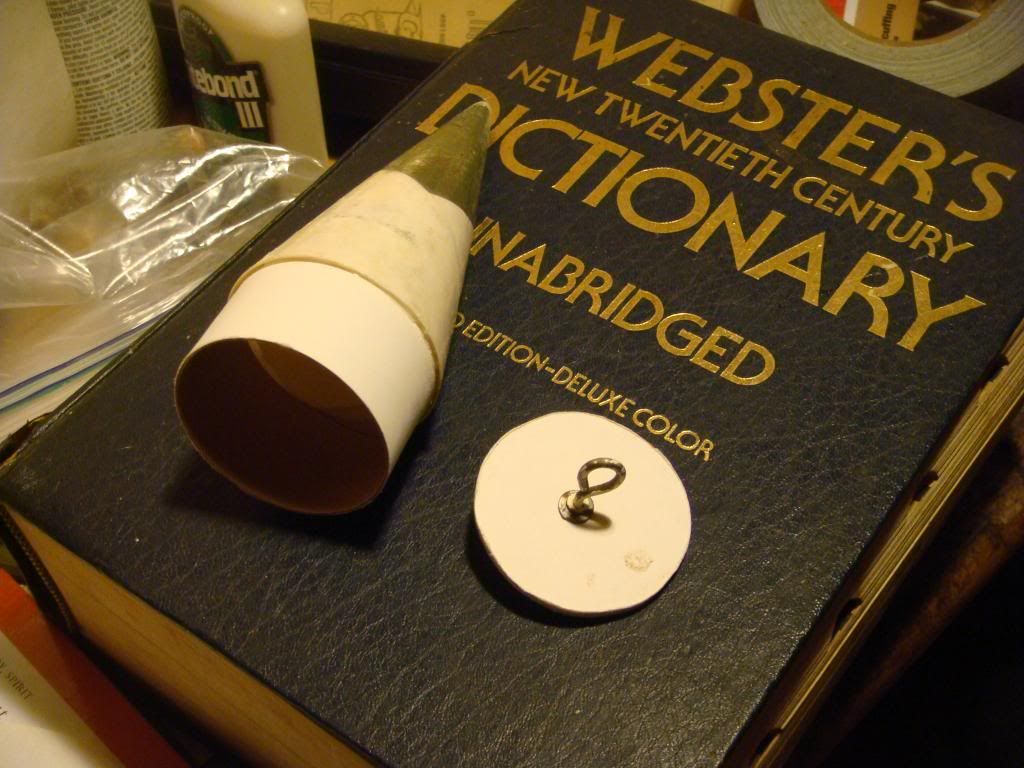

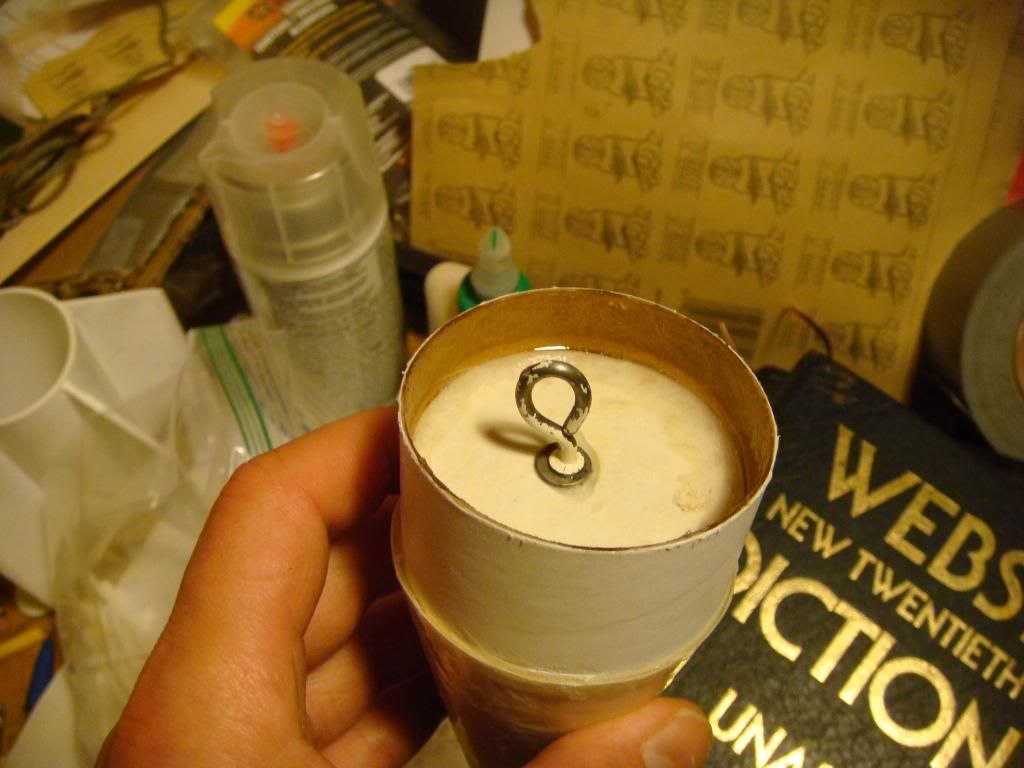

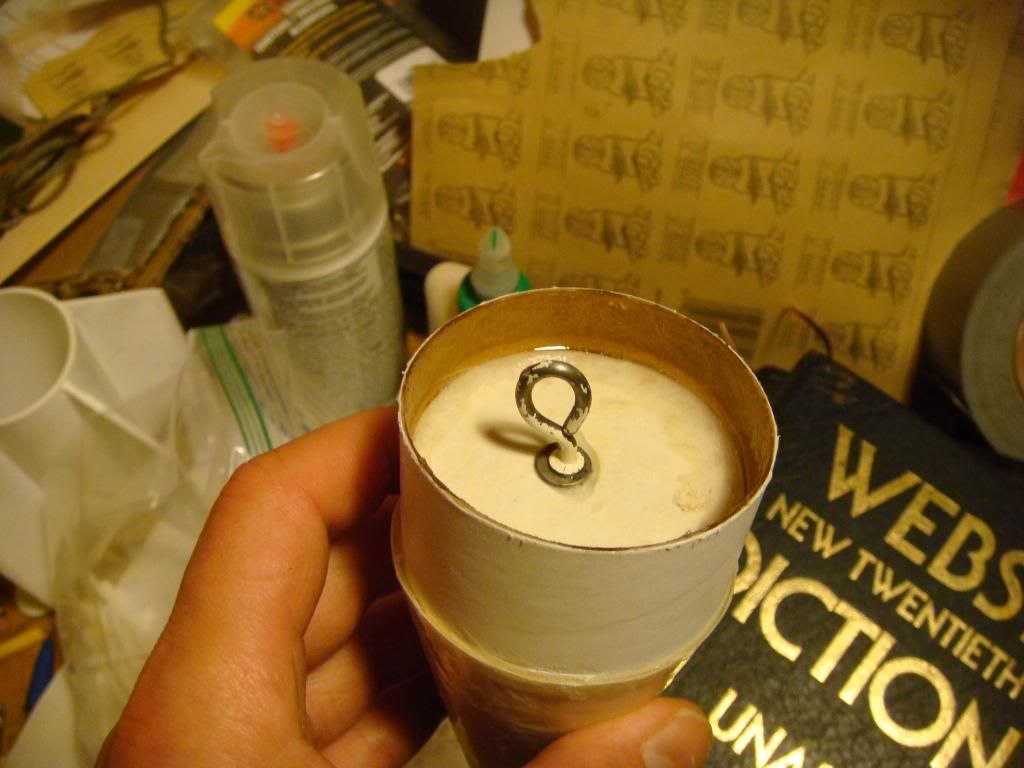

Next, I matched it up to the Body Tube, and did my final trimming of the Base. I then fitted a Coupler to it to allow it to fit into the Body Tube. This was done with 5min Epoxy too. I checked it for fit, and things were looking good, so I set to work making a Bulkhead with a Screw Eye Hook that I bent into a Screw Eye. The Bulkhead itself was fashioned out of 1/8" Balsa, Papered on both sides with the Wood Glue and 80# Paper. I epoxied the Screw Eye on both sides and on the Threads. It would have gone beyond the end of the Threads when I screwed it in, so I added a small washer on the Eye side. This was ofcourse then epoxied into the Coupler.:

This part was not "Finished", but structurally it was done.

ETA: I likely will sim this now that it is taking shape.

Well, here we go!:

Started out with the tip of the old chopped up Cone. Rolled some 80lb. Card Stock around it and held it in place with some Tape to get the general Shape. I took the Cone out and tacked it in a few spots along the Seam with CA. I put a ring of CA around the Base of the small plastic Cone and slid the Paper Part on. Now, I slathered CA all over it, inside and out. When this dried, I trimmed the majority of the obvious excess. I then slathered it inside and out with 5 minute Epoxy. When that was dry, I added clippings of Paper to the inside with Titebond II Wood Glue to stiffen it. I had tried using a Cruciform of Balsa, but that warped it. The next Morning, I sanded the inside to even out the odd shapes of Paper I had fitted. Everything was stiff, so I trimmed some more, and sanded the Base til' it was even and concentric.:

Next, I matched it up to the Body Tube, and did my final trimming of the Base. I then fitted a Coupler to it to allow it to fit into the Body Tube. This was done with 5min Epoxy too. I checked it for fit, and things were looking good, so I set to work making a Bulkhead with a Screw Eye Hook that I bent into a Screw Eye. The Bulkhead itself was fashioned out of 1/8" Balsa, Papered on both sides with the Wood Glue and 80# Paper. I epoxied the Screw Eye on both sides and on the Threads. It would have gone beyond the end of the Threads when I screwed it in, so I added a small washer on the Eye side. This was ofcourse then epoxied into the Coupler.:

This part was not "Finished", but structurally it was done.

Last edited: