- Joined

- Dec 7, 2009

- Messages

- 3,531

- Reaction score

- 2,784

48"..no way that would be insane. It's 46". Tony

48"..no way that would be insane. It's 46". It's one of the ones Loki had on 'special'. I have not done any sims or motor calcs yet. I needed to get the parts together first. I'll come up with the motor specs tonight...and sims as I build it.

Tony

48"..no way that would be insane. It's 46". It's one of the ones Loki had on 'special'. I have not done any sims or motor calcs yet. I needed to get the parts together first. I'll come up with the motor specs tonight...and sims as I build it.

Tony

48"..no way that would be insane. It's 46". It's one of the ones Loki had on 'special'. I have not done any sims or motor calcs yet. I needed to get the parts together first. I'll come up with the motor specs tonight...and sims as I build it.

Tony

How come there are only two fins?

..but I'm not flying the N5800 either.

Tony, good luck and take water!

-Kevin

Looking good! Can you elaborate some on the motor thrust ring you made and how it stays attached?

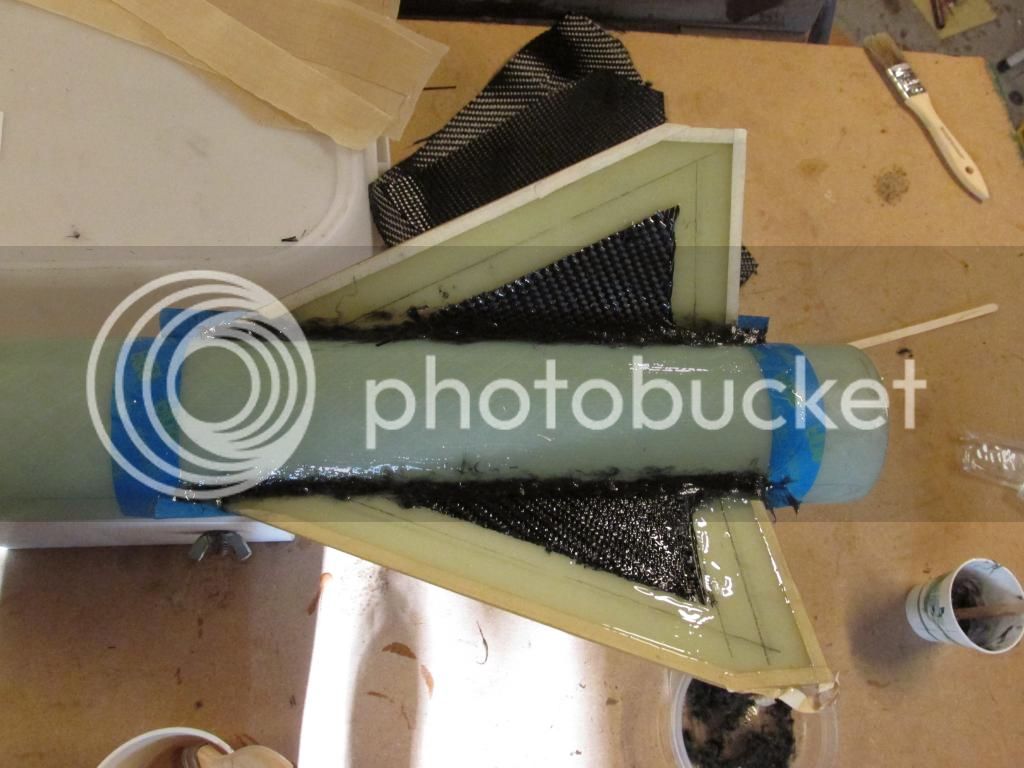

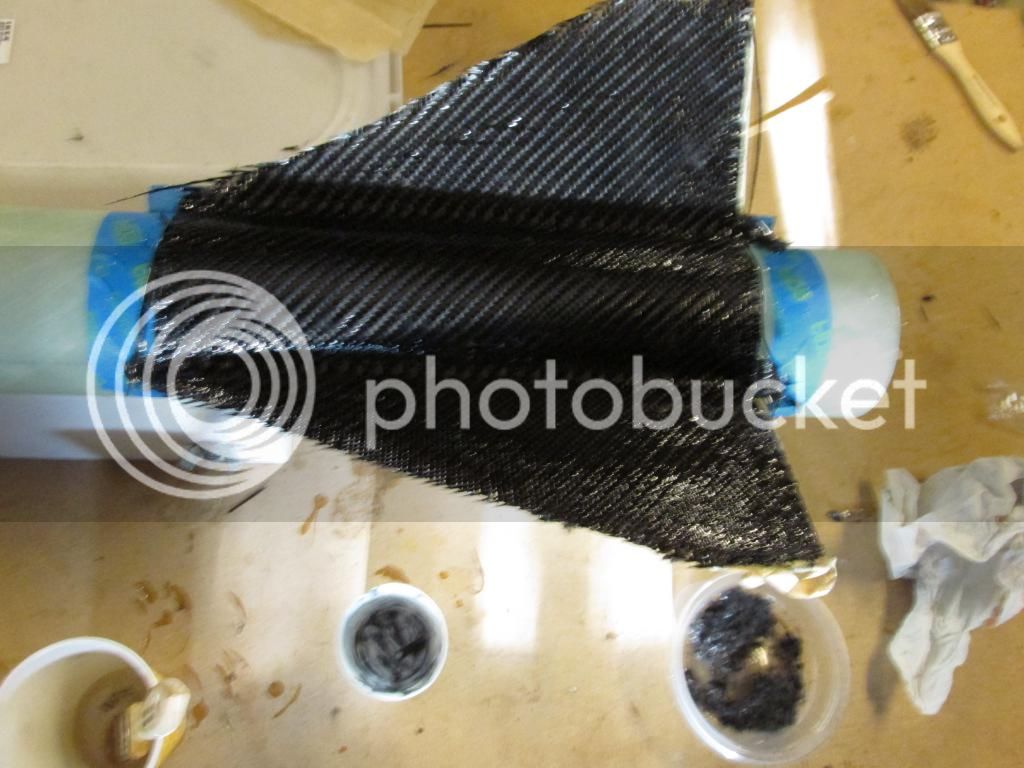

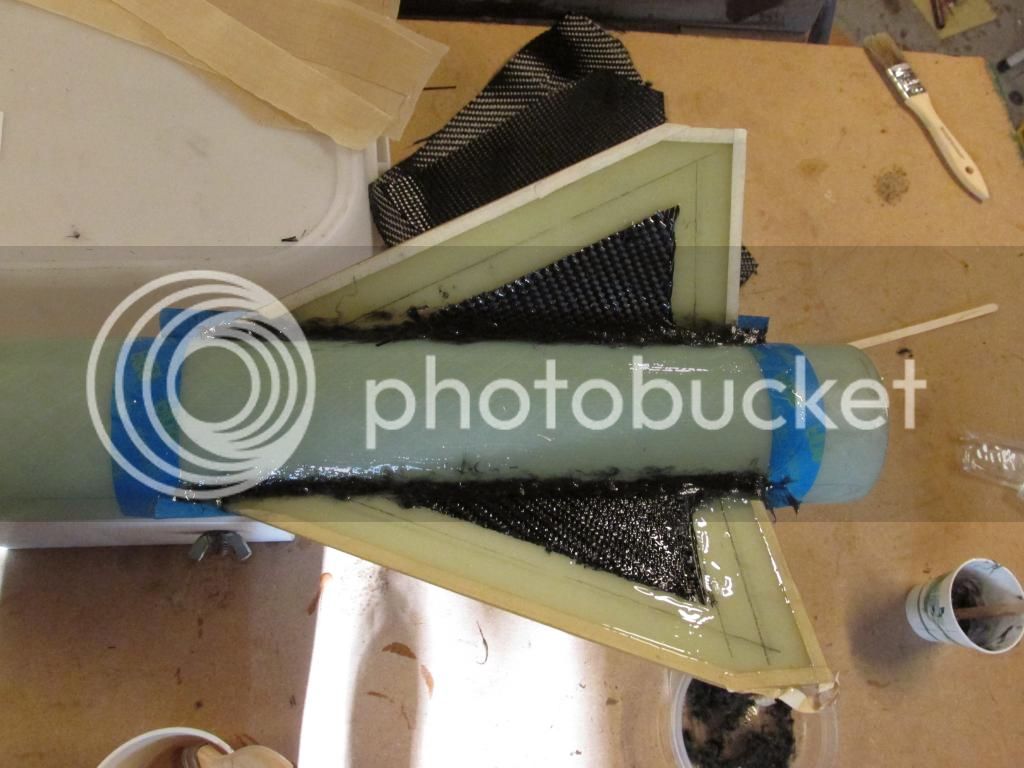

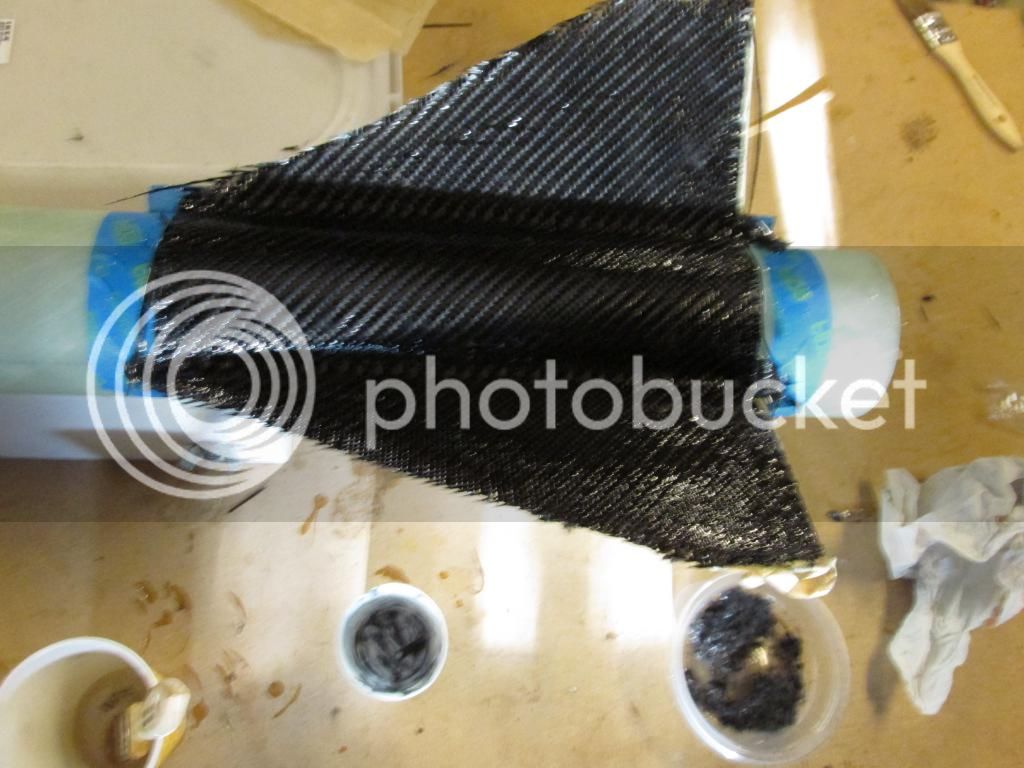

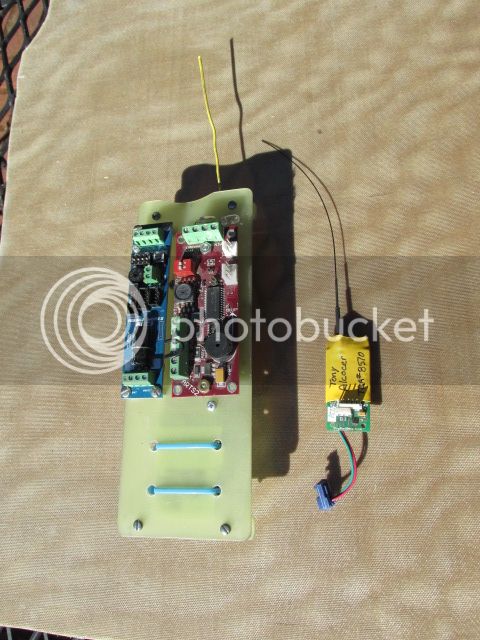

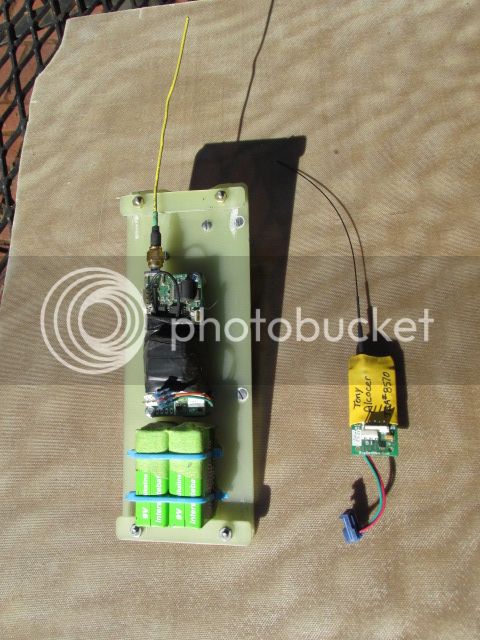

I got one of the bays done .. a bit different then I normally do it.

I went with a couple of small wedge pieces to give the fin a tad more tickness.

There one more piece under this full tip to tip

The peel ply...strips on the filets..a piece that covers the body tube..and one on each fin.

Tony

Wow, looks great!

I noticed the masking tape on your leading, trailing and tip edges. Do you trim the cloth off with a razor and then peel the tape up?

Wow, looks great!

I noticed the masking tape on your leading, trailing and tip edges. Do you trim the cloth off with a razor and then peel the tape up?

Enter your email address to join: