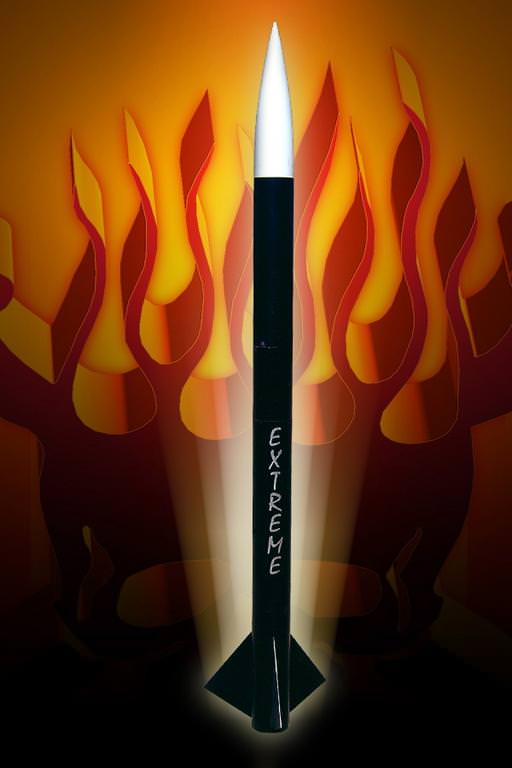

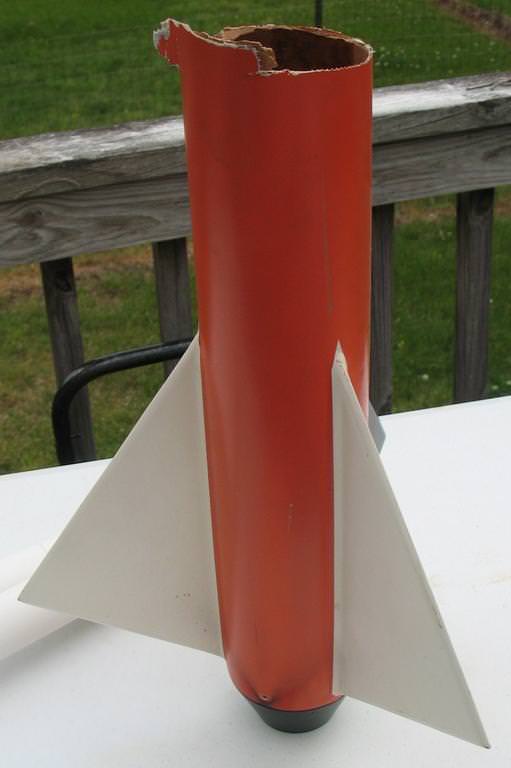

The Black Dahlia before the Rocket Godz took her from me...

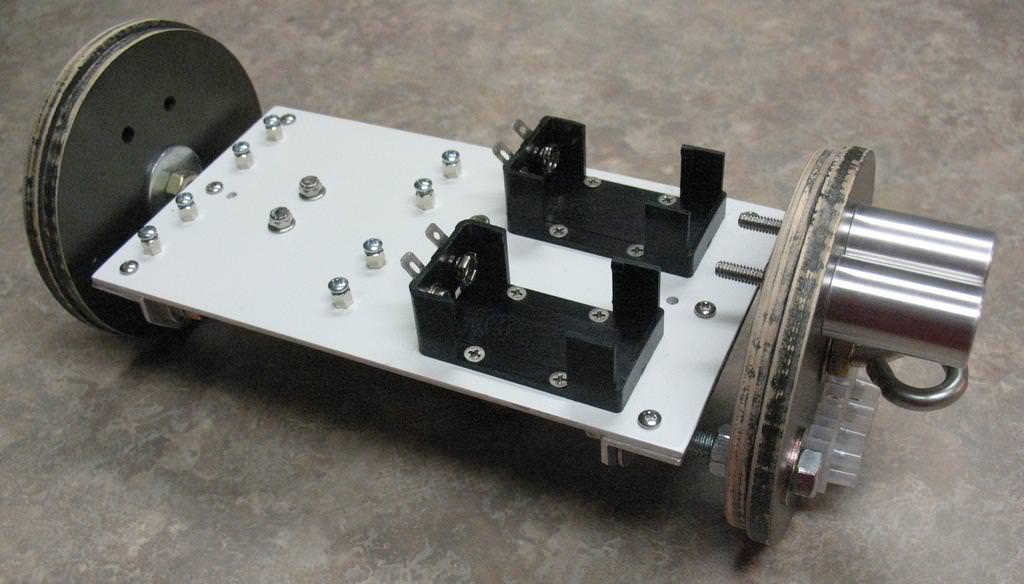

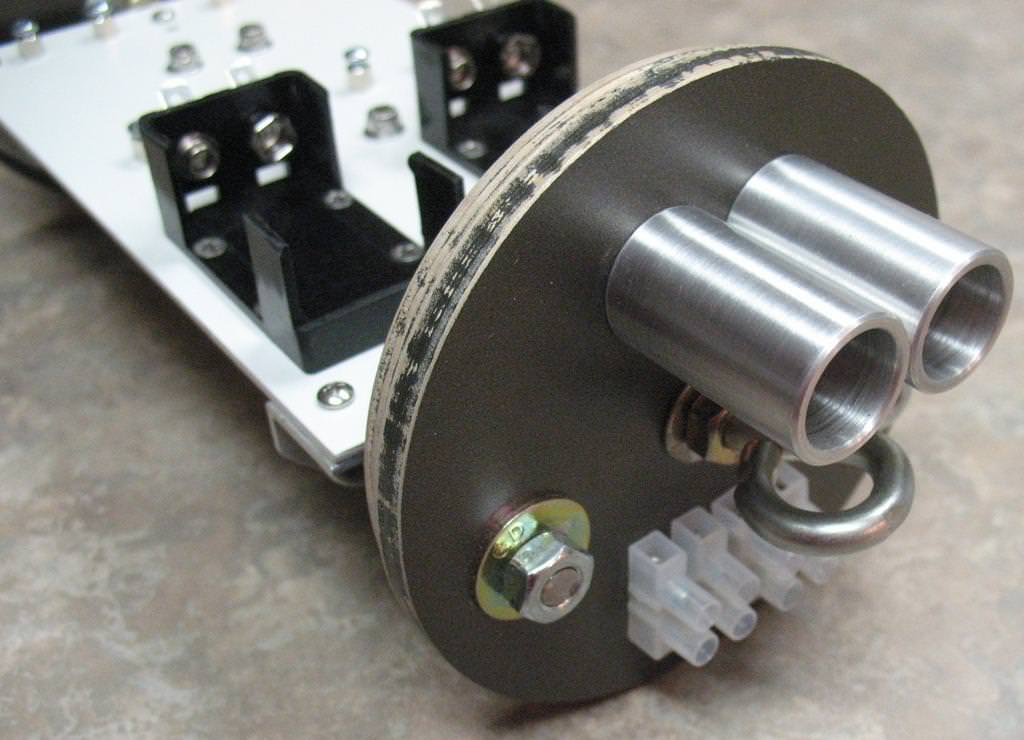

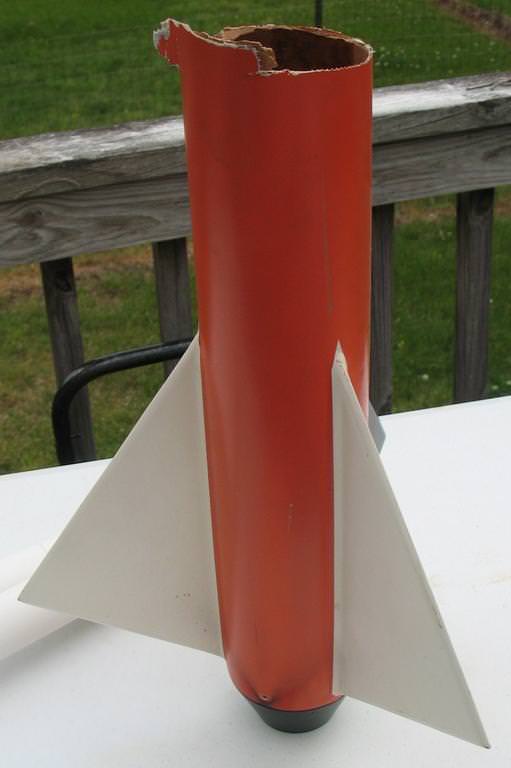

Yeah, I know, no Black paint anywhere. Here is what was left after one of my failed attempts at a parachute controlled landing...

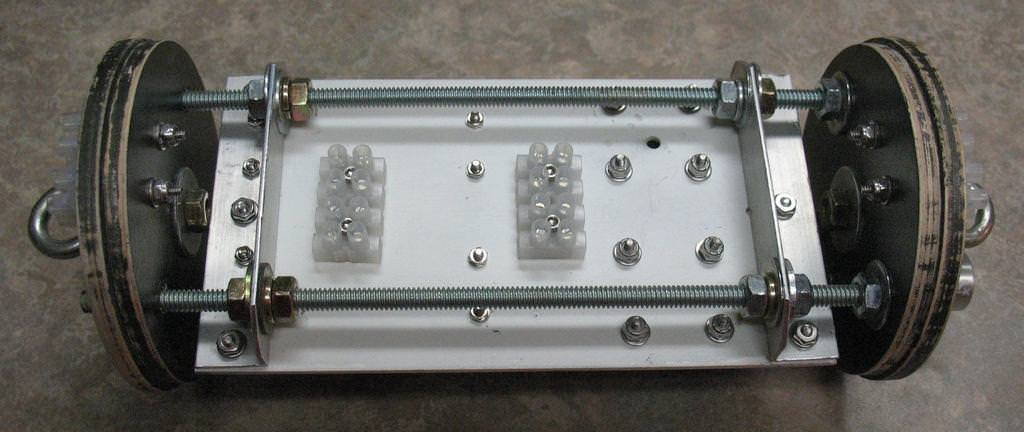

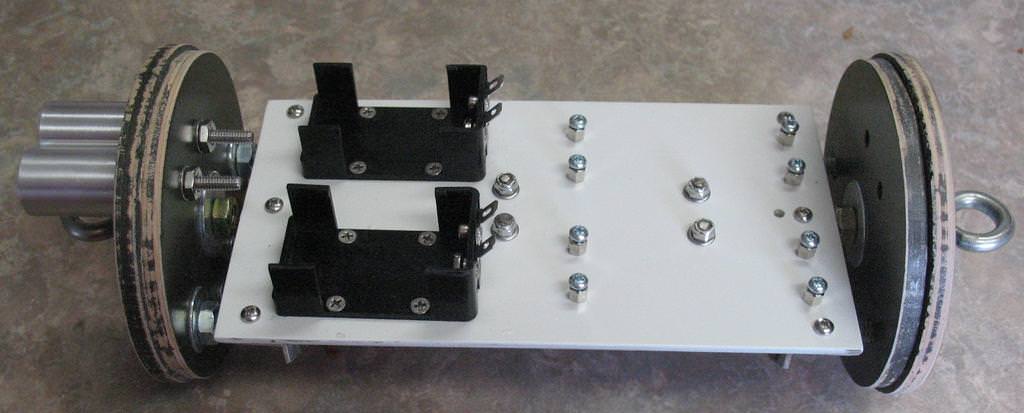

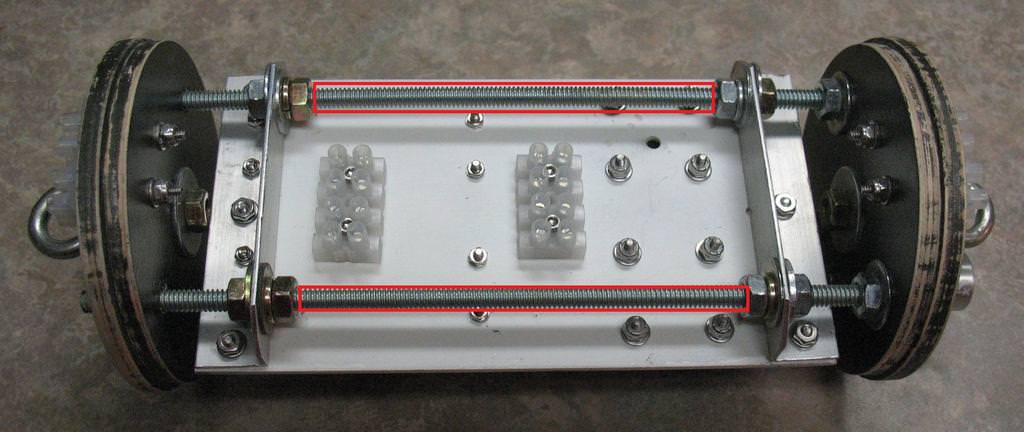

The rocket was originally an old Public Enemy 4" Extreme Performer. When I finished the Black Dahlia basically all that remained of the original kit was the nosecone and the fins... everything else was stretched and modified.

Here are my intended goals for the rebuild:

Here is a video record of her first flight:

[video=youtube;-fyOPxCQvms]https://www.youtube.com/watch?v=-fyOPxCQvms[/video]

It is time to get busy living or get bust dieing...

Yeah, I know, no Black paint anywhere. Here is what was left after one of my failed attempts at a parachute controlled landing...

The rocket was originally an old Public Enemy 4" Extreme Performer. When I finished the Black Dahlia basically all that remained of the original kit was the nosecone and the fins... everything else was stretched and modified.

Here are my intended goals for the rebuild:

- Build a reliable recovery system

- Return to the dimesional shape of the original kit from Public Enemy

- Repair while reinforcing

- New look (I will need some help from Stickershock23 on this one)

Here is a video record of her first flight:

[video=youtube;-fyOPxCQvms]https://www.youtube.com/watch?v=-fyOPxCQvms[/video]

It is time to get busy living or get bust dieing...

Last edited: