Watched Apogee Components videos on YouTube.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do rocket wise today?

- Thread starter BeerorKid

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Flyfalcons

Well-Known Member

- Joined

- Apr 14, 2015

- Messages

- 2,584

- Reaction score

- 912

TangoJuliet

Well-Known Member

- Joined

- Jun 26, 2016

- Messages

- 1,239

- Reaction score

- 13

I ordered a launch pad and a CTI Starter Kit from Heavenly Hobbies.

jeff_j_black

Well-Known Member

- Joined

- Oct 31, 2014

- Messages

- 235

- Reaction score

- 2

OK it wasn't today, but on the 4th I went alone to the local park and flew an A, three B's, two C11's and a D12 in absolute wind free conditions. All but one stayed inside the fenced baseball field I was in. For all the MPR and HPR I enjoy, sometimes it's good to go out and remember what got me into it in the first place.

TangoJuliet

Well-Known Member

- Joined

- Jun 26, 2016

- Messages

- 1,239

- Reaction score

- 13

OK it wasn't today, but on the 4th I went alone to the local park and flew an A, three B's, two C11's and a D12 in absolute wind free conditions. All but one stayed inside the fenced baseball field I was in. For all the MPR and HPR I enjoy, sometimes it's good to go out and remember what got me into it in the first place.

Yes, yes, yes! Good for you :clap:.

OK it wasn't today, but on the 4th I went alone to the local park and flew an A, three B's, two C11's and a D12 in absolute wind free conditions. All but one stayed inside the fenced baseball field I was in. For all the MPR and HPR I enjoy, sometimes it's good to go out and remember what got me into it in the first place.

Sharon and I have been going back to our Estes rockets recently, even leaving a day early for a HPR launch and flying Class 1 rockets before the waiver opens up. I'm painting an Astron Elliptic Sharon built today, and recently finished a Pro Series Ascender 2 stage. We plan to attend Hellfire on the Bonneville salt flats next month, and have a bunch of class 1 rockets to fly on Thursday, the first day of the launch. After flying a bunch of big rockets at LDRS, it's nice to back off a bit and have some simple flights.

markkoelsch

Well-Known Member

- Joined

- Mar 18, 2009

- Messages

- 4,362

- Reaction score

- 160

Who makes that trick fin jig you're using? The last fin jig I had was an Estes one that I got for X-mas back in the early 80's.

I think, and apologize if I am mistaken, TRF user tmacklin is your man for the fin jig.

TangoJuliet

Well-Known Member

- Joined

- Jun 26, 2016

- Messages

- 1,239

- Reaction score

- 13

Thanks. I think I also saw one at the Apogee website. After seeing the price, I've decided I don't need it that bad. :wink:

EXPjawa

Well-Known Member

This was yesterday, actually, but I gave a kit (an extra Estes Equinox) to a friend's 8-yr old son. They came over to discuss buying one of my old race karts, but he found the rockets very interesting...

Estesbasher

Well-Known Member

- Joined

- Mar 29, 2013

- Messages

- 373

- Reaction score

- 48

rocketgeek101

Well-Known Member

Uploaded this weekend's launch video to YouTube

[video=youtube;_uuDPbeHGNQ]https://www.youtube.com/watch?v=_uuDPbeHGNQ[/video]

[video=youtube;_uuDPbeHGNQ]https://www.youtube.com/watch?v=_uuDPbeHGNQ[/video]

EXPjawa

Well-Known Member

- Joined

- Jan 30, 2016

- Messages

- 8,993

- Reaction score

- 3,518

Thanks. I think I also saw one at the Apogee website. After seeing the price, I've decided I don't need it that bad. :wink:

If that jig saves me a couple of BTs and fins over the years it'll be paid off in no time.

If it helps prevent a single shred or prang; an undestroyed airframe, casing, and populated ebay pays it off in about 30 seconds.

- Joined

- Nov 8, 2015

- Messages

- 1,401

- Reaction score

- 78

TopRamen

SA-5

- Joined

- Aug 9, 2013

- Messages

- 9,955

- Reaction score

- 112

I went questing for a free Refrigerator, which I found first, then I found a free paper shredder and some other useful items.

I stripped some foamboard of it's paper layer, and created the item I've been seeing in my dreams for quite a while now.

Highly flexible and durable foam strips, that can be wound in a spiral fashion over the foam or "other" rings and ribs of foam or "other" airframes.

You cannot bend foamboard enough to make it useful as a skin on a mostly foam rocket.

Now, it is not only possible, but convenient, as the shredder does all of the cutting and pressing for me, so I can make the material as needed, in about 5-6 seconds, as long as my foamboard already has the paper layer removed.

It can be wound onto things as small as 2.6" without showing any creasing or breaking. Typical foam construction techniques have you cover the foam with a vinyl wrap or monokote or even paper and clear tape, so the texture is not an issue, and in my circumstance will actually be a beneficial aspect of the material, as I intend to use lightweight glass cloth, so that the final product may be sanded smooth.

I just barely came up with this, so I have only wrapped these around already built rockets and spray cans.

This is going to be an incredibly useful item to me, as I want to build 4" rockets, but my current materials simply cannot skin a rocket that size and leave room for my style of construction technique. I've had a 4" Martel AS37 ready to go for over a month now, but everything that I could build the sin out of was to heavy to allow for the necessary nose weight and motor.

Sure, if I was L1, this weight thing would not be an issue on a 4" rocket, but alas, I fly on my schedule, and the nearest club to me is like 50 or more miles away, and I don't like going that far to do anything.

Now all I need is that foam safe CA, and I can make some crazy stuff!!!

Also made good progress on my lathe, since it was cool and rainy today, and got some of the dollhouse parts sorted.

That's going to take atleast a month, as I made that second trip and got my vehicles capacity worth of what was left and known to be useful. Most of it is in my shed where it can stay dry and I don't have to worry about bringing more mold around my living quarters. None of it looks wet or moldy, as on my second trip I dug out the sealed stuff that was beneath the top layers of rained on stuff.

I stripped some foamboard of it's paper layer, and created the item I've been seeing in my dreams for quite a while now.

Highly flexible and durable foam strips, that can be wound in a spiral fashion over the foam or "other" rings and ribs of foam or "other" airframes.

You cannot bend foamboard enough to make it useful as a skin on a mostly foam rocket.

Now, it is not only possible, but convenient, as the shredder does all of the cutting and pressing for me, so I can make the material as needed, in about 5-6 seconds, as long as my foamboard already has the paper layer removed.

It can be wound onto things as small as 2.6" without showing any creasing or breaking. Typical foam construction techniques have you cover the foam with a vinyl wrap or monokote or even paper and clear tape, so the texture is not an issue, and in my circumstance will actually be a beneficial aspect of the material, as I intend to use lightweight glass cloth, so that the final product may be sanded smooth.

I just barely came up with this, so I have only wrapped these around already built rockets and spray cans.

This is going to be an incredibly useful item to me, as I want to build 4" rockets, but my current materials simply cannot skin a rocket that size and leave room for my style of construction technique. I've had a 4" Martel AS37 ready to go for over a month now, but everything that I could build the sin out of was to heavy to allow for the necessary nose weight and motor.

Sure, if I was L1, this weight thing would not be an issue on a 4" rocket, but alas, I fly on my schedule, and the nearest club to me is like 50 or more miles away, and I don't like going that far to do anything.

Now all I need is that foam safe CA, and I can make some crazy stuff!!!

Also made good progress on my lathe, since it was cool and rainy today, and got some of the dollhouse parts sorted.

That's going to take atleast a month, as I made that second trip and got my vehicles capacity worth of what was left and known to be useful. Most of it is in my shed where it can stay dry and I don't have to worry about bringing more mold around my living quarters. None of it looks wet or moldy, as on my second trip I dug out the sealed stuff that was beneath the top layers of rained on stuff.

Last edited:

- Joined

- Jan 30, 2016

- Messages

- 8,993

- Reaction score

- 3,518

Would foam weather strip serve a similar function? I have a hunch it would be too heavy / dense, but I imagine it to be available in different weights.

In any case, neat!

In any case, neat!

TopRamen

SA-5

- Joined

- Aug 9, 2013

- Messages

- 9,955

- Reaction score

- 112

Would foam weather strip serve a similar function? I have a hunch it would be too heavy / dense, but I imagine it to be available in different weights.

In any case, neat!

Thanks, but yes, it is the wrong type of foam, the gooey type, so it cannot be sanded or cut with precision easily. It is much heavier.

This is the exact item I was seeing in my dreams, and it is available for virtually nothing. I like the black color dollar store foam board, as it is slightly less brittle that the white stuff, and that must be why it is a whole 35 cents more than a dollar per sheet. The paper peals off easier too.

I have enough stocked up that I use entire sheets for the silliest things. 6 of them taped together side by side make a nice surface for me to drive my vehicle onto so that I don't tear my clothing on the rocks in my driveway when I'm under there looking at stuff or working, and a few more taped together and taped to the sides of the vehicle mean that I don't have to come out into the hot and bright sun as I wriggle out from under it.

I'm considering building a garage out of it.

Last edited:

TopRamen

SA-5

- Joined

- Aug 9, 2013

- Messages

- 9,955

- Reaction score

- 112

I now have plenty of lite ply to reinforce it with, and then some, so making pieces for tie down hard points is no longer an issue.Thanks, but yes, it is the wrong type of foam, the gooey type, so it cannot be sanded or cut with precision easily. It is much heavier.

This is the exact item I was seeing in my dreams, and it is available for virtually nothing. I like the black color dollar store foam board, as it is slightly less brittle that the white stuff, and that must be why it is a whole 35 cents more than a dollar per sheet. The paper peals off easier too.

I have enough stocked up that I use entire sheets for the silliest things. 6 of them taped together side by side make a nice surface for me to drive my vehicle onto so that I don't tear my clothing on the rocks in my driveway when I'm under there looking at stuff or working, and a few more taped together and taped to the sides of the vehicle mean that I don't have to come out into the hot and bright sun as I wriggle out from under it.

I'm considering building a garage out of it.

I'll face more challenges attaching it to the Earth than I will with the construction of the structure itself.

I can't go Geodesic, as it has to look like a real garage.

I'm weird enough as it is, and in WWII, inflatable "Ghost Airfields" and the like won the day sometimes.

By doing my garage out of foamboard, I can make a grid on the top, and position a mirror in a different grid square everyday, with a written record to accompany said position.

When I finally see an updated satellite picture online, I'll be able to know when it was taken.

The last one I anilized showed my puffy white Dog in enough detail to tell it was my Dog, as seen from space.:surprised:

Problem was, yeah, she is sometimes in the yard, but what time?

The sad/bad part is that just like looking up through the atmosphere, they likely used a laser or microwave to get that degree of resolution, so when I am capable of retaliatory measures, they will be enacted swiftly and in an equally non-chalant fashion.

Ironically, a person I know and am related to helped develop that system, so while I could actually just go defeat them physically, they don't even know me anymore, so it only makes sense to defeat them virtually instead.

Using lasers to cut through the atmosphere is a pretty douchebag thing to do, especially if they are looking down.

Flyfalcons

Well-Known Member

- Joined

- Apr 14, 2015

- Messages

- 2,584

- Reaction score

- 912

Finished shaping, and started sheeting, the Flying V.

- Joined

- Nov 8, 2015

- Messages

- 1,401

- Reaction score

- 78

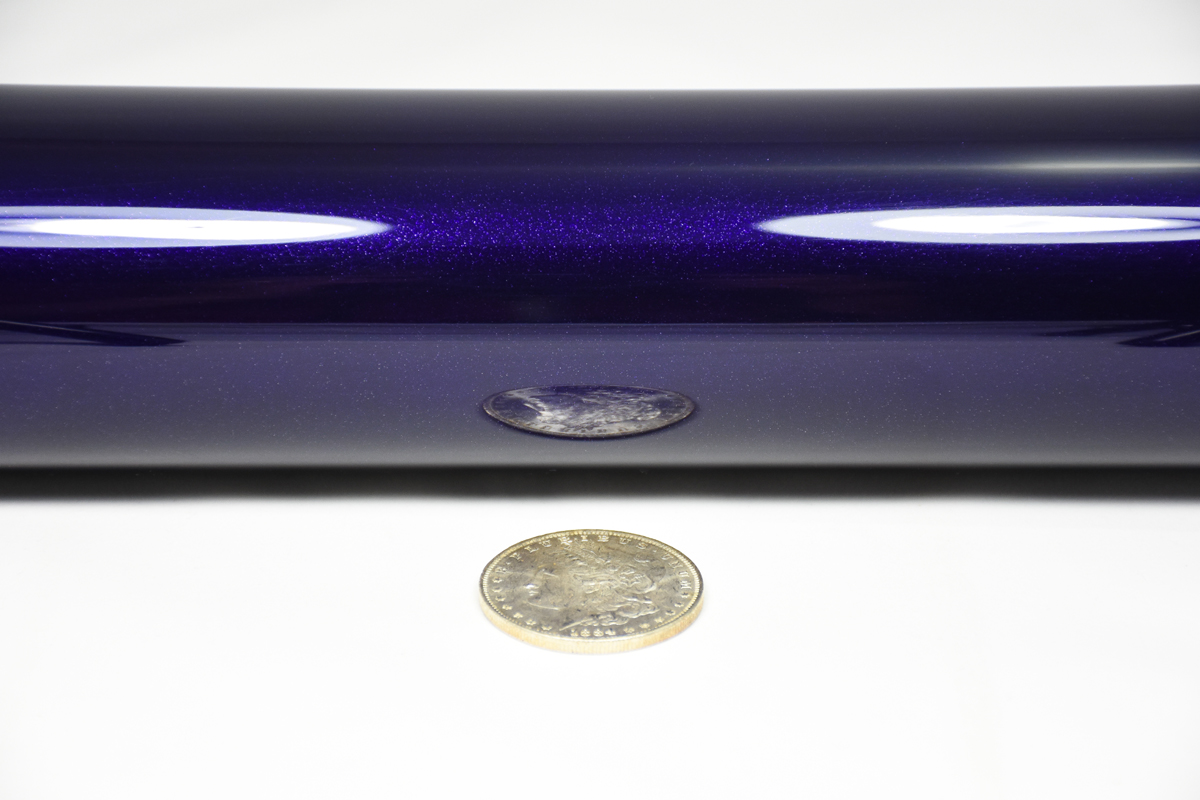

Spent some time sanding and polishing my 2.6" Super DX3. Not finished yet, trying to get it finished in time for MDRA next week. Here is a sneak preview. . .

Wow. You are really talented when it comes to a rocket finish!! I was impressed with the one I saw out at Culpepper, by this is a work of art!!

o1d_dude

'I battle gravity'

Made a couple of 38mm paint spikes from 1" PVC pipe and used masking tape wraps to build up a ledge to keep the motor tube from sliding all the way down. Hoping to shoot primer tomorrow on my Madcow Lil Goblin 38mm.

blackjack2564

Crazy Jim's Gone Banana's

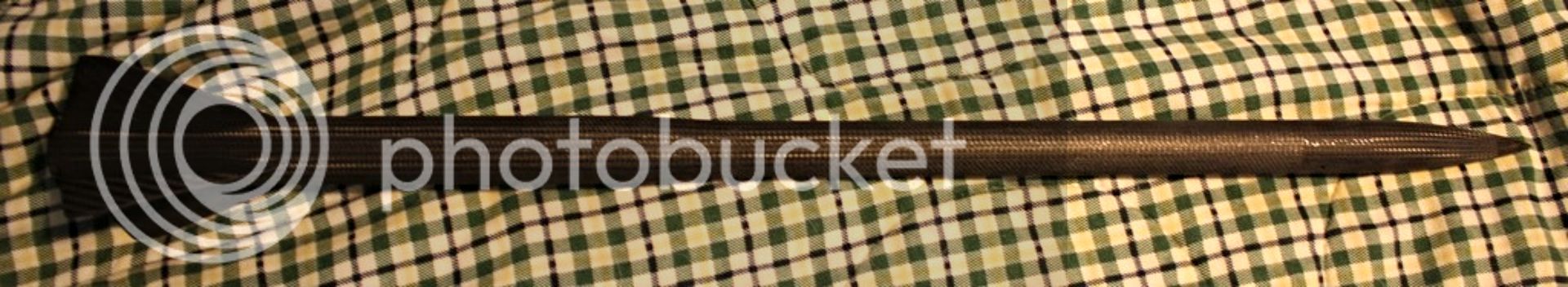

Finished tweaking this design. 3in screamer.......

Fins cut [4] carbon uni-plate.

Tube rolled 11 layers carbon uni-prepreg.

Coupler rolled double wall thickness, carbon uni..blah..blah..bla.

Main in NC.

Test mule for telemetry.

External antenna on 3 in vent band.

We shall seeeeeeeee..........should be very interesting!!!!:dark:

Assembly begins tomorrow.

Fins cut [4] carbon uni-plate.

Tube rolled 11 layers carbon uni-prepreg.

Coupler rolled double wall thickness, carbon uni..blah..blah..bla.

Main in NC.

Test mule for telemetry.

External antenna on 3 in vent band.

We shall seeeeeeeee..........should be very interesting!!!!:dark:

Assembly begins tomorrow.

Last edited:

Finished tweaking this design. 3in screamer.......

View attachment 296603

Fins cut [4] carbon uni-plate.

Tube rolled 11 layers carbon uni-prepreg.

Coupler rolled double wall thickness, carbon uni..blah..blah..bla.

Main in NC.

Test mule for telemetry.

External antenna on 3 in vent band.

We shall seeeeeeeee..........should be very interesting!!!!:dark:

Assembly begins tomorrow.

Anywhere I can follow this build?

Flyfalcons

Well-Known Member

- Joined

- Apr 14, 2015

- Messages

- 2,584

- Reaction score

- 912

Made good progress on the Flying V. Also stopped at a hobby shop and they had a Maxi Alpha III for 15 dollars, so I snagged that for the build pile.

o1d_dude

'I battle gravity'

Put down a coat of primer on the MC Kil Goblin 38mm and spread a coat of glazing putty on the fin fillets.

Also sanded the gelcoat of the nosecone to eliminate the molding marks so that I can put on the first cost of primer tomoorow morning before it gets to hot.

Also sanded the gelcoat of the nosecone to eliminate the molding marks so that I can put on the first cost of primer tomoorow morning before it gets to hot.

blackjack2564

Crazy Jim's Gone Banana's

:wink:

By the way this is the one I offered you to fly, but you said you didn't have anywhere to do it.

I may do some assembly type build, but the actual process of making all the parts is proprietary. What is being used is purchased by the pound, not the yard. Shipped frozen & must be kept frozen till use. Shelf life of 6 weeks.

400.00 just in carbon for 1 tube, 1 NC coupler & 4 fins. Fins glued on with another proprietary product then T-T with several layers carbon uni-prepreg, vacuum bagged. 750 degree high temp epoxy, & commercial ablatives.

If this flies as good as expected, it will be paired with a 4in booster. N to M.. carrying 2lb payloads [can-sats] to 90-100,000ft . Testing on smaller motor this fall at Airfest if finished by then. Working on imbedding telemetry antennas in airframe skin as it's carbon & they must be on exterior surface.

It takes too much time to photo document everything, as in a normal build thread. There is an unbelievable amount of research in this project. End result will be a spin stabilized sustainer for the Sparrow Hv-Arcus. Charlie's working on a Disc-gap-band chute for withstanding deployment & decent at mach speeds. Samples of tubing were sent out to a lab, for various tests...shear, compression, hoop, etc. Results are fantastic.

Here's a tease . So now it begins.............

Look carefully you can see shadow of motor in booster, only 9inches for recovery gear,between top of motor & I/S.

I'll hobble something together next week after some assembly. :wink:

Anywhere I can follow this build?

By the way this is the one I offered you to fly, but you said you didn't have anywhere to do it.

I may do some assembly type build, but the actual process of making all the parts is proprietary. What is being used is purchased by the pound, not the yard. Shipped frozen & must be kept frozen till use. Shelf life of 6 weeks.

400.00 just in carbon for 1 tube, 1 NC coupler & 4 fins. Fins glued on with another proprietary product then T-T with several layers carbon uni-prepreg, vacuum bagged. 750 degree high temp epoxy, & commercial ablatives.

If this flies as good as expected, it will be paired with a 4in booster. N to M.. carrying 2lb payloads [can-sats] to 90-100,000ft . Testing on smaller motor this fall at Airfest if finished by then. Working on imbedding telemetry antennas in airframe skin as it's carbon & they must be on exterior surface.

It takes too much time to photo document everything, as in a normal build thread. There is an unbelievable amount of research in this project. End result will be a spin stabilized sustainer for the Sparrow Hv-Arcus. Charlie's working on a Disc-gap-band chute for withstanding deployment & decent at mach speeds. Samples of tubing were sent out to a lab, for various tests...shear, compression, hoop, etc. Results are fantastic.

Here's a tease . So now it begins.............

Look carefully you can see shadow of motor in booster, only 9inches for recovery gear,between top of motor & I/S.

I'll hobble something together next week after some assembly. :wink:

Last edited:

:wink:

By the way this is the one I offered you to fly, but you said you didn't have anywhere to do it.

I may do some assembly type build, but the actual process of making all the parts is proprietary. What is being used is purchased by the pound, not the yard. Shipped frozen & must be kept frozen till use. Shelf life of 6 weeks.

400.00 just in carbon for 1 tube, 1 NC coupler & 4 fins. Fins glued on with another proprietary product then T-T with several layers carbon uni-prepreg, vacuum bagged. 750 degree high temp epoxy, & commercial ablatives.

If this flies as good as expected, it will be paired with a 4in booster. N to M.. carrying 2lb payloads [can-sats] to 90-100,000ft . Testing on smaller motor this fall at Airfest if finished by then. Working on imbedding telemetry antennas in airframe skin as it's carbon & they must be on exterior surface.

It takes too much time to photo document everything, as in a normal build thread. There is an unbelievable amount of research in this project. End result will be a spin stabilized sustainer for the Sparrow Hv-Arcus. Charlie's working on a Disc-gap-band chute for withstanding deployment & decent at mach speeds. Samples of tubing were sent out to a lab, for various tests...shear, compression, hoop, etc. Results are fantastic.

Here's a tease . So now it begins.............

View attachment 296692

Look carefully you can see shadow of motor in booster, only 9inches for recovery gear,between top of motor & I/S.

I'll hobble something together next week after some assembly. :wink:

Well I'm looking forward to seeing how this turns out. When do you expect to be finished building it?

Similar threads

- Replies

- 158

- Views

- 6K

- Replies

- 5

- Views

- 304

- Replies

- 19

- Views

- 2K

- Replies

- 1

- Views

- 989