rharshberger

Well-Known Member

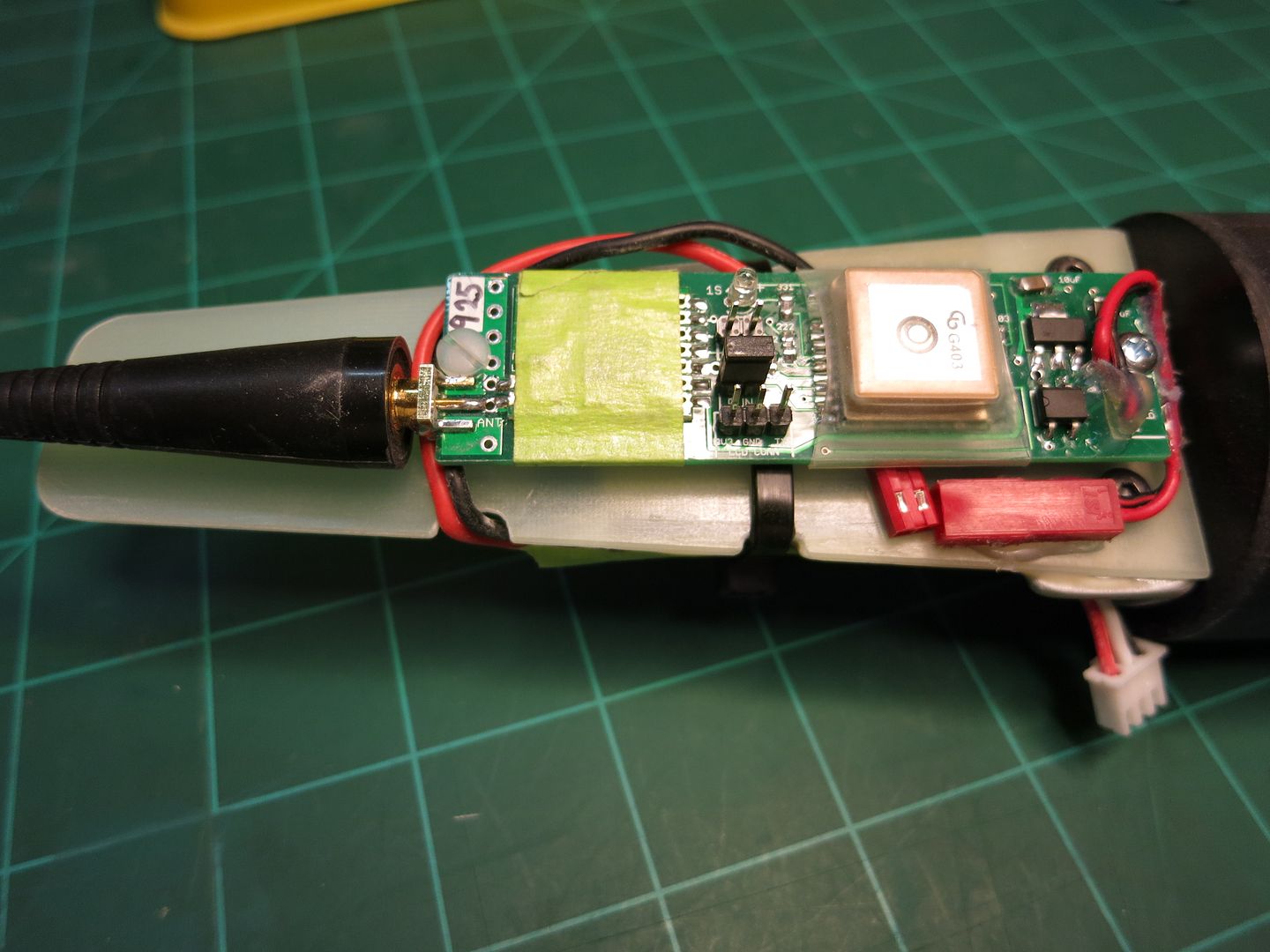

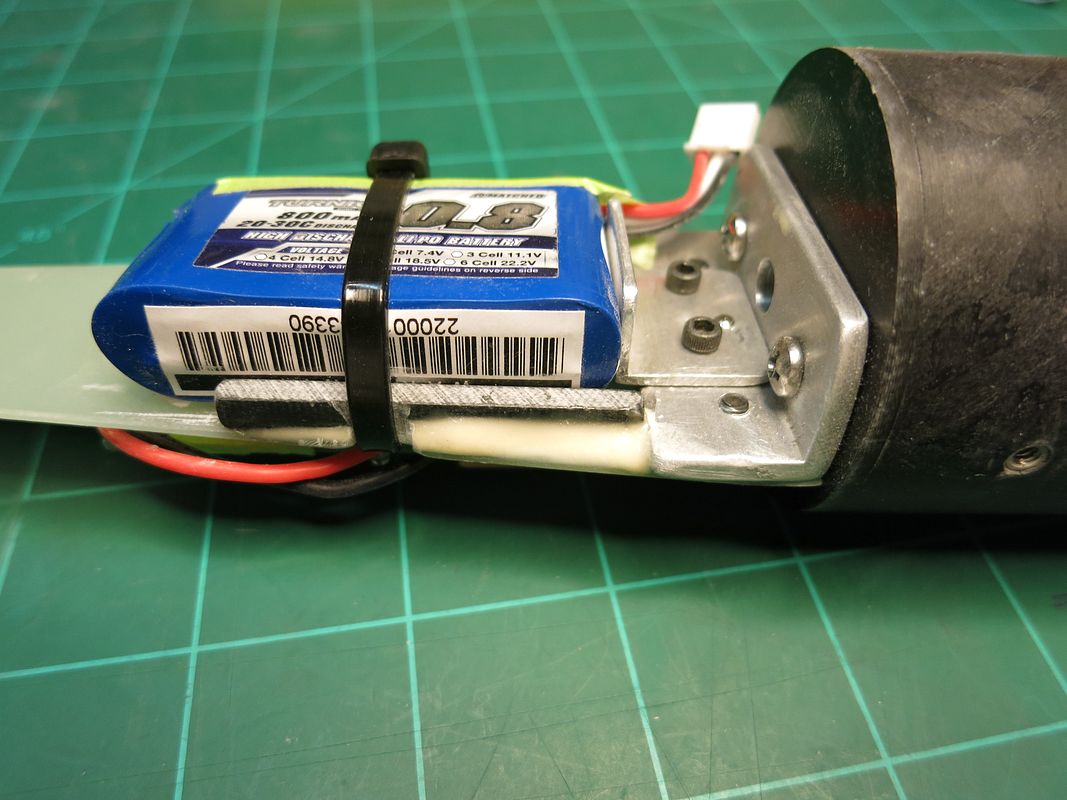

Did some more work on my L3 project a Cherokee-D upscale. Looked at the partially completed Big Daddy...then went back to work on the Cherokee-D.

https://www.rocketryforum.com/showt...t-Cherokee-D-L3-build-thread-for-rharshberger

https://www.rocketryforum.com/showt...t-Cherokee-D-L3-build-thread-for-rharshberger

Last edited: