Igotnothing

Well-Known Member

- Joined

- Oct 26, 2014

- Messages

- 997

- Reaction score

- 209

As of last night, "Legionnaire's Revenge" is ready to fly (ignore the mess...need to get another shelf):

View attachment 303316

What mess? I see no mess.

As of last night, "Legionnaire's Revenge" is ready to fly (ignore the mess...need to get another shelf):

View attachment 303316

Last year I built this Hyperloc 835 for my L2. It was named "Legionnaire's Lament":

View attachment 303318

I failed:

View attachment 303317

I discovered the speed limit of unreinforced balsa! Estes Star Orbiter, stock build save for a baffle installed in the coupler and buttons in place of lugs ...

Economax G74-9W to (guessing) 1800+ ... up and down parts good, but figuring sometime near motor burnout the balsa more or less disintegrated!

From the ground it was a good clean flight until I went to recover and found this:

View attachment 303426

View attachment 303427

Definitely not landing damage

I tried to talk my son into letting me have one of his frisbees, which would have made an awesome saucer rocket. He wouldn't let me.

Found this "Vacmaster" thing on the side of the road in a free pile, and am hoping that I can adapt it to do vacuum bagging on fg and cf stuff.

It appears to work, but I have no idea what it is supposed to do other than package food, so I need to look up the owners manual and find a wiring schematic to get the heating element out of the way or whatever I have to do to try to make use of the vacuum pump inside. I'm clueless, but have other projects going on right now so there's plenty of time to figure out if it will be useful.

View attachment 303620

Found this "Vacmaster" thing on the side of the road in a free pile, and am hoping that I can adapt it to do vacuum bagging on fg and cf stuff.

It appears to work, but I have no idea what it is supposed to do other than package food, so I need to look up the owners manual and find a wiring schematic to get the heating element out of the way or whatever I have to do to try to make use of the vacuum pump inside. I'm clueless, but have other projects going on right now so there's plenty of time to figure out if it will be useful.

View attachment 303620

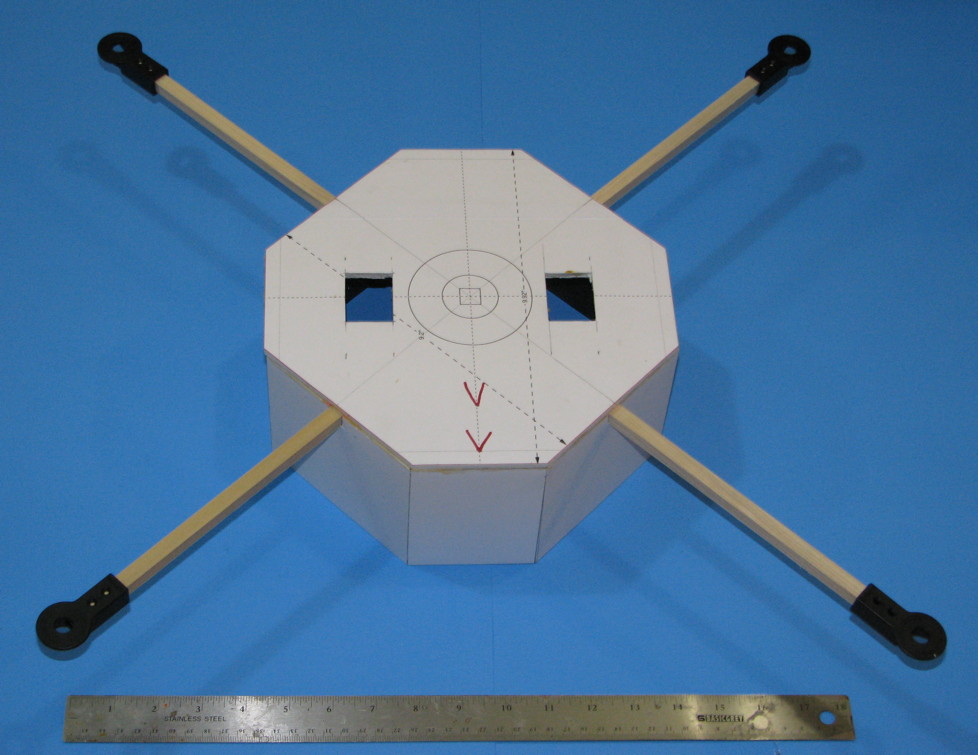

"Finished" my Quinstar, although I may do a clear coat.

Used calligraphy ink applied with a foam brush and some sharpies

View attachment 303656

Enter your email address to join: