TangoJuliet

Well-Known Member

- Joined

- Jun 26, 2016

- Messages

- 1,239

- Reaction score

- 13

Started assembling an Estes Big Daddy. Threw out the thrust ring and motor clip, and also replaced the stock shock cord with 300# Kevlar and 1/4" Bungee from Apogee.

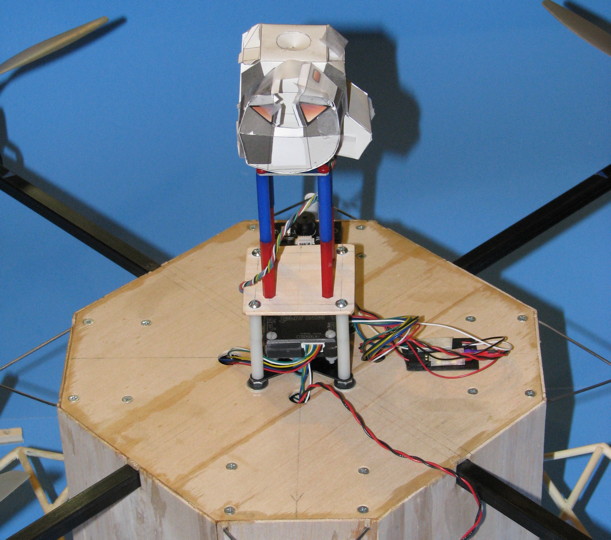

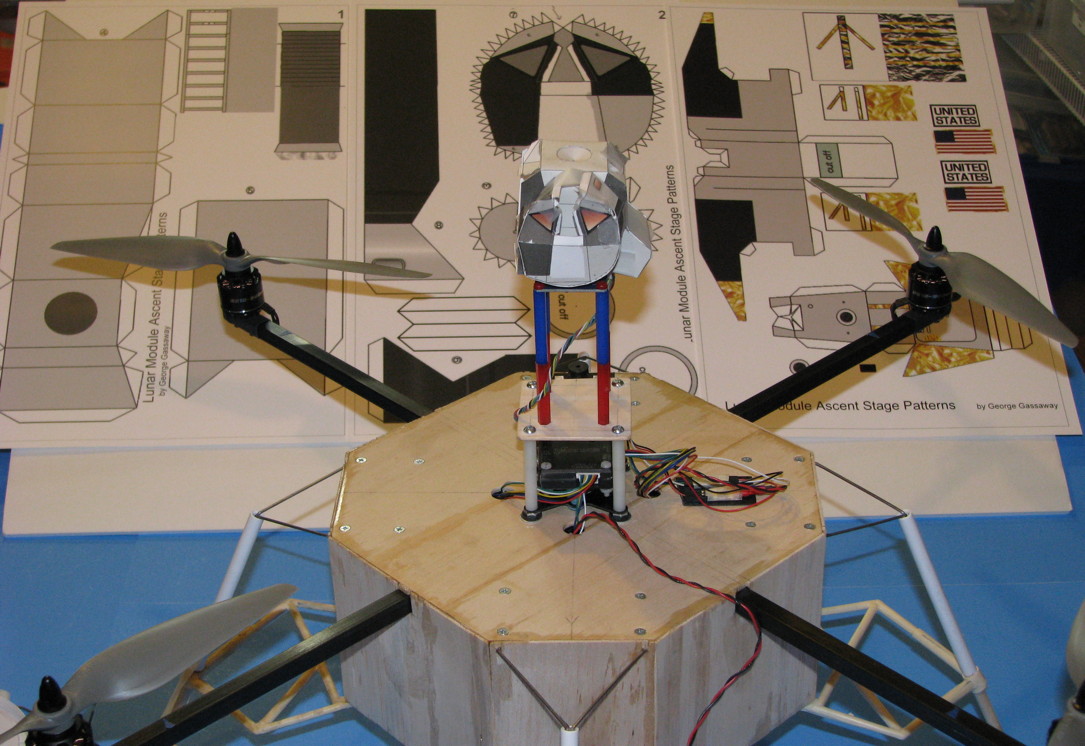

Performed a post-mortem analysis on my Terrordactyl. She will fly again with not too much effort. But my eggtimer TRS took a beating on landing. Cris has already been helpful in advising me how to repair it.

View attachment 306727

It looks like my electronics worked well: Both the drogue and main changes fired, but they didn't separate the airframe. There is black soot everywhere inside the payload and booster. These were identical to the charges that I had ground tested, but I suspect that the powder wasn't packed tight enough. It probably dispersed during the flight. I need to work on my charge prep technique. Lesson learned.

I filled out the paperwork to start a hobby rocketry company.

Whaaaa???? Details?

I will be waiting to post an official announcement until all the details are done. So far I have filled out the paperwork to register an assumed business name, created a web domain, did a market survey (https://www.rocketryforum.com/showthread.php?137397-New-rocketry-product-feedback-request), and started to make the production tooling. I still need to build the website/store, talk to potential vendors and distributors, negotiate pricing, build initial inventory, and do some quality testing. Once that is complete (mid January-ish) I will make a big official announcement.

Broke a friggin' carbide drill in a piece of stainless steel. And I'm seriously torqued off about it.

Broke a friggin' carbide drill in a piece of stainless steel. And I'm seriously torqued off about it.

Performed a post-mortem analysis on my Terrordactyl. She will fly again with not too much effort. But my eggtimer TRS took a beating on landing. Cris has already been helpful in advising me how to repair it.

View attachment 306727

It looks like my electronics worked well: Both the drogue and main changes fired, but they didn't separate the airframe. There is black soot everywhere inside the payload and booster. These were identical to the charges that I had ground tested, but I suspect that the powder wasn't packed tight enough. It probably dispersed during the flight. I need to work on my charge prep technique. Lesson learned.

Enter your email address to join: