Got the bandsaw moved into the house with my Son, then went and got a new belt for it.

I'll have to clean her up real nice and do a fair amount of re-working the wiring, and a few other things, but then I'll be using bandsaw tactics on rocketry.

She runs, and would do fine for just cutting stuff, but I might as well get to know her inside and out first, like any decent machine worth knowing.

My very first lathe was given to me by my Grandpa, when I was 18 and had taken up gunsmithing as a hobby first, then as a gun salesman and correspondence course trained gunsmith.

He sure must have thought I was a smart one, because it was only a lathe in definition. In reality it was a box, containing all the parts of a lathe, and not just any lathe, but something that was probably made in the 20's from what I could learn in the Library by doing research.

After about a year, and many conversations on the phone with my Grandpa, I had something of the most hideous aspect, yet it would turn things like trigger assembly retention pins for shotguns or similar simple parts with reasonable certainty and much practice.

I had not learned annealing, hardening, tempering or any real forms of heat treatment yet, so the parts were only made when they were absolutely not going to affect safety in any way, so stuff like firing pins or safety parts I had to say no to making, but when a customer comes in with an old Sears/Stevens/Savage whatever, and there is a No.2 Wooden Pencil retaining the trigger assembly, a call to GPC might yield.... a part in a week, when you can make it from a drill bit or brass nail in a few hours if you are careful....

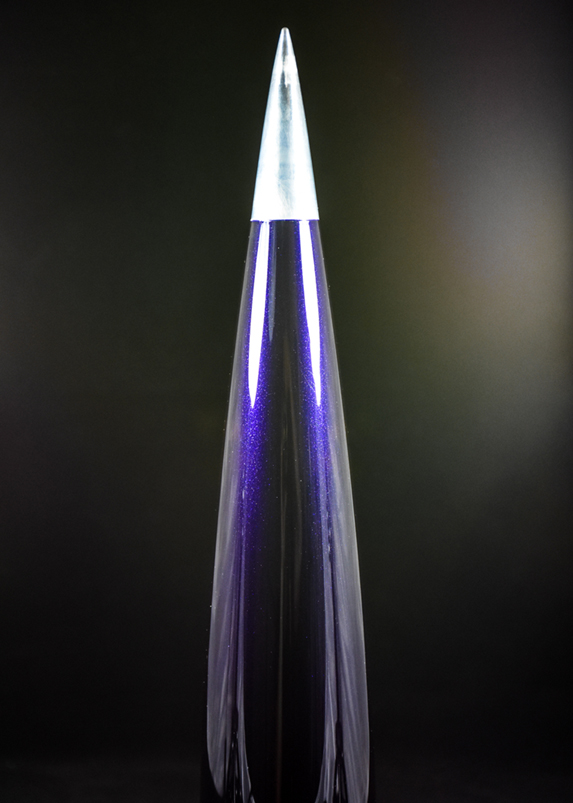

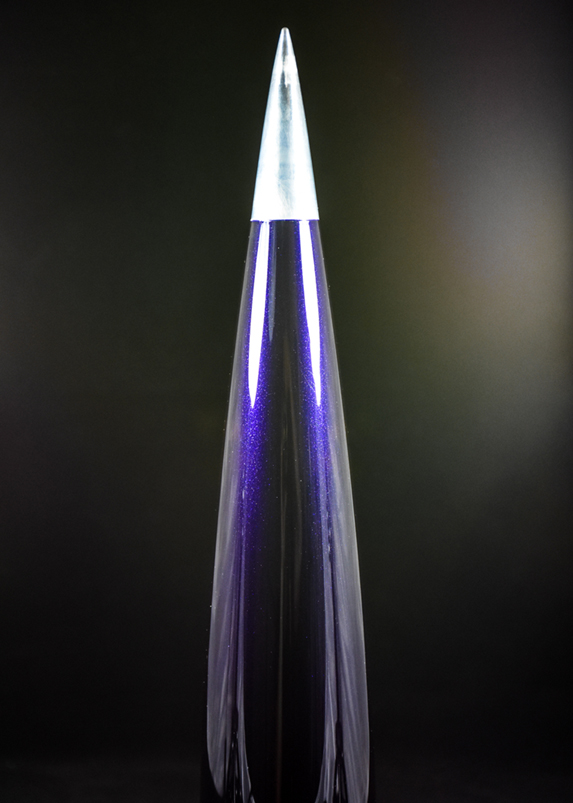

Anyhow, I'm honored to have the unit and to have it right here not five feet from me to marvel at.

Because all the parts were well made when they were made, the highest cost in cleaning it up will only be some effort and work on my part.

The upper wheel guard has had a rough go at the years, but I suspected the original sizing and dimensions could be found in the lower wheel guard, as I suspect they are typically made from identical castings.

I believe that I can remove the imperfections from the top one, then use the bottom one as a "Control" for what the top one should be.

If I have to skeletonize the top one in places, I will do so in perforations, then add the mass back to the area in lead, covered in carbon fiber, which will all be invisible under a coat of gray paint, like the original supposedly was.

I'm only "Ankle Deep" into the research, but am already blown away by how bandsaws are just as cool as I always thought they were.

With a bandsaw and a drill press, I could build a bandsaw and a drill press in a reasonable enough amount of time that I could give them to someone who would do the same thing with them. Tools that can make tools, or even rudimentary clones of themselves are awesome!

Other than that, I spent the day at the hardware store and lumber store getting stuff to fix my house.

Too bad my house can't build me a new house.

I fit a 4'X8' sheet of 3/4" plywood in the back of my Yukon XL, and someone said "It's really much larger on the inside than it looks from here.", and I totally got a kick out of that, as I'm a Doctor Who fan, but by no means a "Whovian".