sugardaddy

Well-Known Member

- Joined

- Oct 12, 2010

- Messages

- 211

- Reaction score

- 0

Hi Guys,

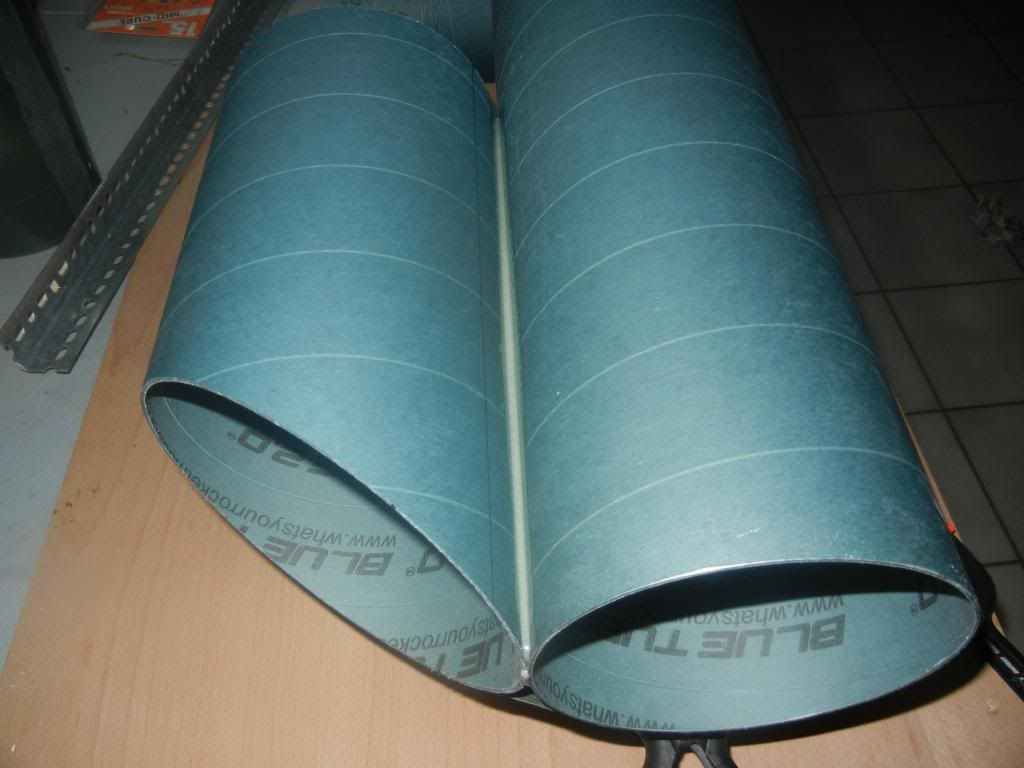

I have decided to take the plunge and go for my L3. My rocket of choice will be a scratch built 6" tube fin made from Blue Tube.

Since i did my L2 on "Going Postal" a 3" duel deployment tube fin, I felt I needed to do the same for L3. My cert flight will be made on a Gorilla M1665WC.

This isnt going to br a masterpiece or anything like that, I'm just building a monster tube fin design to pass a cert flight.

Pics are coming up.

Danny

I have decided to take the plunge and go for my L3. My rocket of choice will be a scratch built 6" tube fin made from Blue Tube.

Since i did my L2 on "Going Postal" a 3" duel deployment tube fin, I felt I needed to do the same for L3. My cert flight will be made on a Gorilla M1665WC.

This isnt going to br a masterpiece or anything like that, I'm just building a monster tube fin design to pass a cert flight.

Pics are coming up.

Danny